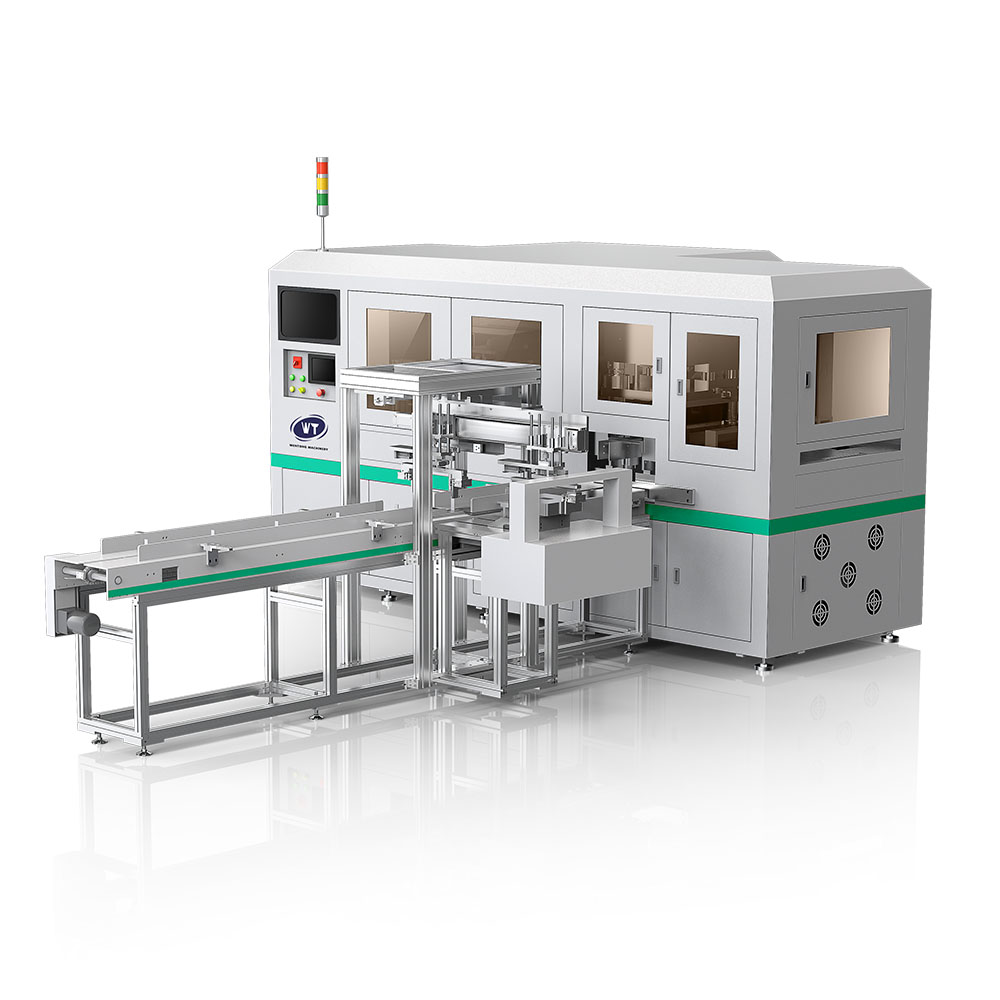

Cards are more than just tools for identification and payment. They also represent brand reputation, security level and user experience. In the global card manufacturing industry chain, cards have evolved from basic identity recognition and payment tools to high-value collectibles and security carriers. Manufacturing quality, especially the contour precision, edge texture, and degree of production automation, has become the most important factor for manufacturers to compete in the international market. Shenzhen Wentong Machinery, which is at the forefront of innovation in China, has created and released the core equipment for the global high-end market – the fully automatic transparent card die-cutting machine. This is due to the company’s deep understanding of precision machinery manufacturing and automatic control technology. This machine does more than just punch holes like a standard die-cutting machine. It has advanced functions such as high-precision servo punching, intelligent visual recognition, automatic classification and sorting, and flexible card collection. It aims to provide global card-making enterprises with a set of efficient, stable and customisable integrated production solutions. These solutions will help them cope with the challenges of modern production, which include small batches, multiple varieties, and high standards.

2. Main uses and positioning of transparent card die-cutting machine

The equipment is designed to meet the highest standards of the card manufacturing industry in terms of quality, efficiency and flexibility. It accurately covers and defines the entire range of high-end card production:

- Financial payment and secure identity recognition: The equipment is suitable for the final forming and punching of various cards such as credit cards, debit cards, social security cards, ordinary card layers of resident identity cards, personal information page carriers of electronic passports, high-end access control cards, and membership cards. Its burr-free technology ensures the complete flatness of the chip module embedding and magnetic stripe fitting area, avoiding wear and tear in later use.

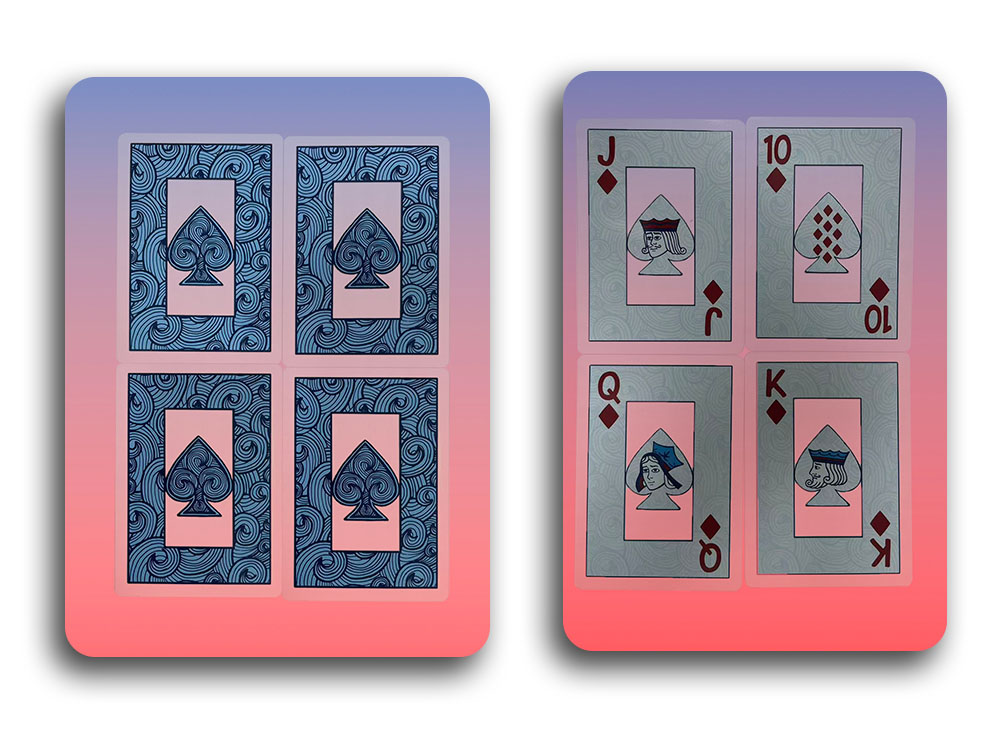

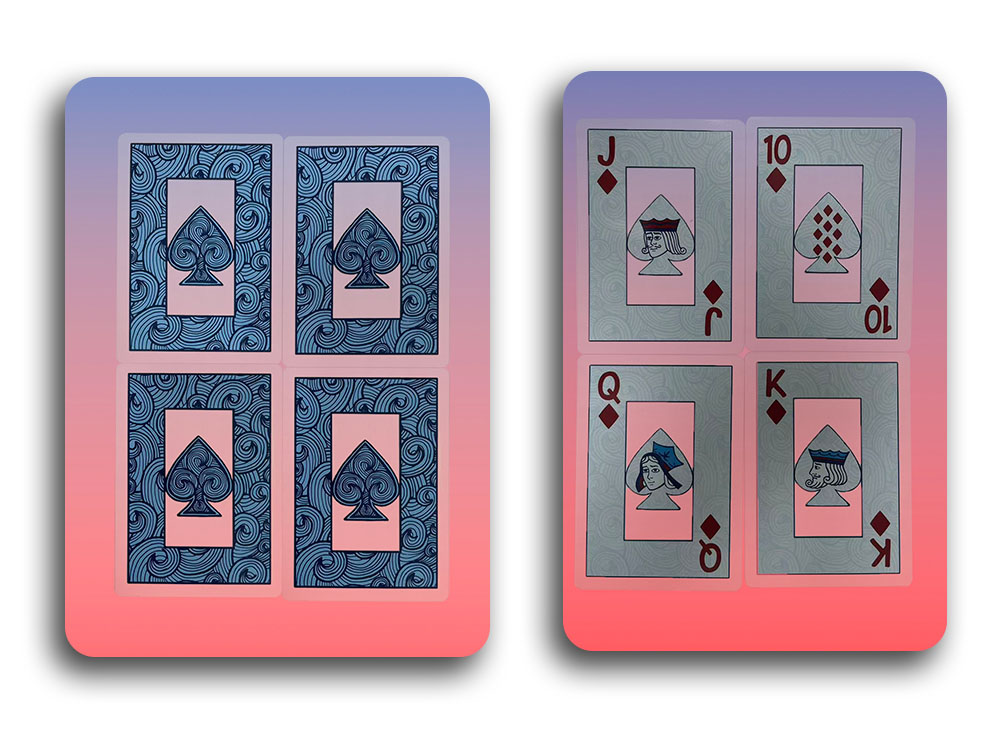

- Entertainment and collectables: The system is ideal for collectable cards such as Magic: The Gathering, Yu-Gi-Oh!, and Pokémon, as well as sports cards, anime cards, luxury playing cards, and promotional scratch cards. Its built-in automatic classification and sorting system can directly send cards with different patterns, series, or rarity to different places according to what it sees, which makes packaging and transportation much easier.

- IoT and communication basic parts: With the popularity of 5G and IoT, the demand for card slot carriers remains stable. The equipment can punch SIM card carriers, eSIM card white cards, M2M module cards, and various RFID/UHF label cards with high precision. This ensures that the dimensions meet international standards (such as ISO/IEC 7810), the material properties are stable during high-speed punching, and the chip function is not affected.

- Special materials and new process cards: In order to meet the market demand for personalised products, the equipment has been specially optimised for transparent PVC, PETG, acrylic composite materials, metal composite layers, local screen printing or film-coated materials. Whether it is a fully transparent card, a semi-transparent frosted card, or a perfect substrate for partial UV, hot stamping, or laser engraving, the punching and cutting edges can be guaranteed to be clear and transparent or neat and clean.

- Cross-industry precision punching and cutting applications: The platform has been successfully extended to high-end hardcover book covers (such as hot stamping letterpress and special-shaped book covers), industrial-grade filter materials (such as HEPA filter pre-cut type and laboratory precision filter paper), medical test paper contours, electronic consumer goods internal insulation gaskets and other fields, showing a strong process adaptability.

3. Ten core features and technological advances of the transparent card die-cutting machine

This device is the best because it is constantly improving and striving for excellence in ten different areas. It’s not just a list of features; it’s a complete technical response to the pain points of the industry.

①Unique texture display: perfectionism at the microscopic level

The “high-end feel” of the card is first touched by the fingertips. When traditional die-cutting is used, it is easy to produce fibre burrs or fine cracks, which are particularly obvious on transparent or light-coloured cards and are regarded as quality defects. The equipment completely solves this problem through three technologies:

- Rigid Fortress: The one-piece high-strength cast iron body is optimised by finite element analysis (FEA), and the pre-tightened precision roller guide rail makes the stamping process free from deformation and vibration, providing a completely stable working environment for precision tools.

- Precise power control: The 7.5 kW full closed-loop servo drive system can precisely control the downward speed of the punch, the pressure application curve, and the return time. For different materials such as soft PVC or hard PETG, the best “fast-slow-fast” punching curve can be programmed to obtain a cutting effect that is more like “precise tearing” rather than rough punching.

- Blade Collaboration: Our unique blade angles and coating treatments, in collaboration with special steel blade manufacturers, cut polymer materials at optimal speed and pressure. The final result is that the punched edge is as smooth as a mirror under a 20x magnifying glass, without drawing, white edge, or chipping. The transparent cards punched out in this way look very neat and crystal clear.

② Better durability: A reliability commitment based on engineering data

The return on investment (ROI) of manufacturing equipment is closely related to its frequency of use. Quantifiable engineering data forms the core durability indicator of the equipment:

- Service life of core components: Key transmission components such as the main shaft and bearings are all heavy-duty products of top international brands such as SKF and THK. The design life is more than 20,000 hours. The high-precision gearbox uses oil bath lubrication to maintain a stable temperature for a long time and minimise wear.

- Structural fatigue strength: The main stress points of the fuselage have undergone more than 10 million times of dynamic load simulation tests to ensure that there is no structural fatigue risk in the long-term use of the rated tonnage.

- Maintenance cycle: According to the status monitoring data, the recommended main maintenance interval (such as replacing the hydraulic system filter element, re-lubricating the guide rail, etc.) is 1.5 to 2 times longer than that of traditional equipment. This reduces maintenance costs and shortens maintenance time.

③ Multi-purpose: modular design, variable production capacity.

To keep up with the market trend of “small batches and multiple batches”, the equipment needs to be very flexible. The machine has a modular quick-change system:

- Quick die change platform: It adopts a hydraulic or mechanical die locking device and a standardised die base and can change and position the whole set of upper and lower dies within 5-10 minutes. After mould change, the repeated positioning accuracy can be maintained at ±0.01 mm.

- Programmable pressure stroke: The human-machine interface (HMI) can save and call the stamping settings (pressure, speed, and pressure holding time) of different products. From stamping 0.5mm-thick PVC cards to stamping 3mm-thick hardcover book covers, you only need to call the correct recipe.

- Expansion interface: The frame is reserved with standard electrical and pneumatic interfaces, which is convenient for adding an automatic waste removal device, an online visual inspection module for detecting the punching quality, and a synchronous signal interface connected with the printing machine, hot stamping machine and other front and rear processes.

④ Seamless connection with post-press processes such as hot stamping: Ensure correct offline positioning processing.

Many high-end card products need to be hot stamped, embossed, and partially varnished after they are made. The equipment design takes into account the process series connection:

- High-precision positioning system: The worktable is equipped with a precision optical positioning ruler or an optional mechanical positioning pin to ensure that the semi-finished product has a stable and uniform reference edge when it is transferred to the offline hot stamping machine. In this way, the secondary processing can be accurately positioned.

- Process data compatibility: The equipment control system can record and output the coordinate data of the starting point of the punching and cutting of each batch of products. It provides data support for the process equipment that needs digital alignment in the future and ensures that the position of the hot stamping pattern relative to the card edge or the original pattern on the card surface is always correct.

⑤Mature and stable technology: the mechatronics that has been tested by the market

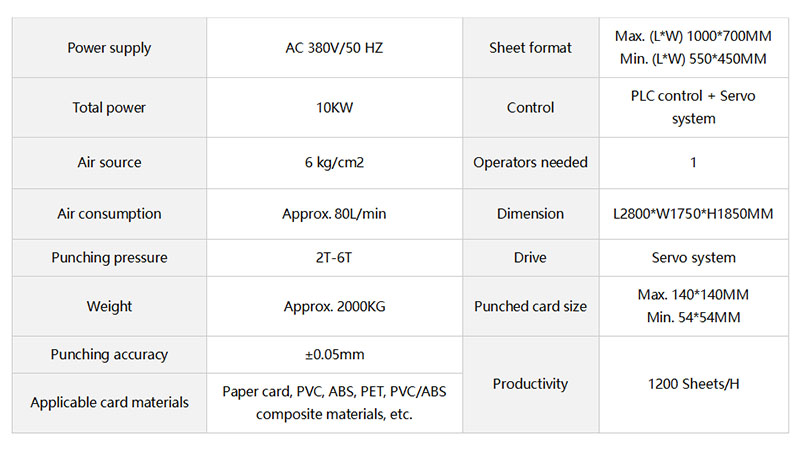

The device is not just a collection of new technologies but a natural combination of old technologies. The heart of the control system is an industrial-grade programmable logic controller (PLC). It controls all motion sequences and logic. It has a more stable architecture than a commercial PC and is more resistant to interference. It has a high-resolution colour touch screen, a graphical wizard-style operation interface, and can support multiple languages. All electrical components meet international safety standards such as CE and UL. They can also work in factories with different voltages around the world.

⑥ One-stop personalised mobile line design from raw materials to finished products

We know that the best performance of a machine does not always mean that the production line is running at its best. That’s why we offer motion design and integration services for production lines, tailored to each customer’s needs:

- Front-end feeding scheme: According to the type of raw materials of customers, an automatic feeding rack for coil materials (with tension control and visual deviation correction) or an automatic feeding machine for single sheet materials can be adopted.

- Mid-process integration: This machine can be used as the host for connecting stations such as online printing quality inspection and chip function testing.

- Customised back-end output: The main automatic sorting, diversion and collection system will be customised according to the finished product processing logic to form a complete production closed loop.

⑦ Revolutionary automatic classification and sorting function

This is one of the most important additional features of the equipment. Most of the time, sorting systems use high-resolution CCD vision systems or RFID readers:

Working principle: After the punching and cutting are completed, the finished card enters the visual inspection area, and the camera quickly captures the pattern, colour, pre-printed QR code or serial number and other information on the surface of the card. The system compares the image features with the preset categories in the database. It then sends instructions to high-speed pneumatic or electric levers that guide the cards to the correct collection channel in less than 100 milliseconds.

When making game cards, the game cards can be divided into “ordinary cards”, “rare cards”, “flash cards” and so on. When making bank card blanks with chips, it can be connected to the front-end test station to automatically sort out “good products”, “communication defective products” and “chip damaged products”. When making personalised cards, it can automatically distinguish cards of different customers or orders. This can reduce manual sorting by more than 75% and completely eliminate human error.

⑧7.5 kW full closed-loop servo drive system technology advantages

The servo system is the most important part of the modern high-end die-cutting machine. This machine adopts a 7.5 kW large torque servo motor and a high-precision encoder to realise full closed-loop feedback control:

- Energy-saving effect: The servo system only uses energy when stamping or cutting and uses very little energy when not working. This is different from the traditional asynchronous motor, flywheel, and clutch drive mode. Overall, it can save 30% to 50% of energy costs.

- Accuracy and speed: The displacement control accuracy can reach 0.01 mm, and the maximum stamping speed can reach 8,000 times per hour, depending on the complexity of the mould. At the same time, the bottom dead centre position of each stamping is always consistent. This is the most important point to ensure the consistency of the size of the batch products.

- Intelligent: The servo system can monitor the load change in real time. If an abnormality is detected, such as a double sheet or foreign object in the mould, it can be stopped immediately, and an alarm can be issued to ensure the safety of the mould and equipment.

⑨Customised finished product collection method: adapt to different types of production management needs.

You need to pick up the cards you have sorted out neatly. There are two main data acquisition methods for the device, as well as some variations:

- Mode 1: Strict order collection. The cards are stacked on the collection table in the order they are punched. This is important for ID cards that need to be kept in strict order and consecutively numbered tickets or cards that need to be matched one by one with personalised data. You can add automatic counting and batch separation functions to the collection device.

- Mode 2: Intelligent sorting and collection. Each sorting outlet is connected to the sorting system and has its own collection container, such as a stacking box, chute or conveyor belt. When the container is full, it can be automatically prompted or automatically replaced. This mode can directly comb the production process to ensure that the packaging link is clear and smooth and is suitable for multi-variety mixed-line production, promotional card package filling, waste isolation and other scenarios.

⑩ Burr-free precision blanking

The final accuracy is only guaranteed when all subsystems work together. We ensure that our promises are kept through strict quality control and final inspection:

- Process control points: including the processing precision of the mould (using slow wire cutting and optical curve grinding), the flatness and parallelism of the equipment workbench (≤0.02 mm/m), and the perpendicularity of the slider movement trajectory to the workbench (≤0.01 mm/300 mm).

- Final inspection standard: The three-coordinate measuring machine (CMM) is used to sample and inspect the batch trial production samples. The diagonal dimension error of the card shape is stable within ±0.05 mm, which fully meets or even exceeds the requirements of the ISO/IEC 7810 ID-1 standard. To ensure the “no hand feel” standard, burrs are detected by both fingertip touch and magnifying glass.

Manufacturing partner for the future

With the global manufacturing industry shifting to intelligent and flexible manufacturing, simply providing hardware can no longer meet the needs of large manufacturing enterprises. Shenzhen Wentong sells not only a transparent card die-cutting machine but also an intelligent production module that can be customised in multiple dimensions, interact with data, and be constantly updated. We hope to establish long-term cooperative relationships with card manufacturers, printing companies and people in various industries who need precision punching and cutting around the world. Together we will meet market challenges, improve production efficiency and product quality, and provide customers with the tools they need to gain a strong competitive advantage in their respective fields. Feel free to contact us at any time to discuss the possibilities of developing a solution that suits your needs.