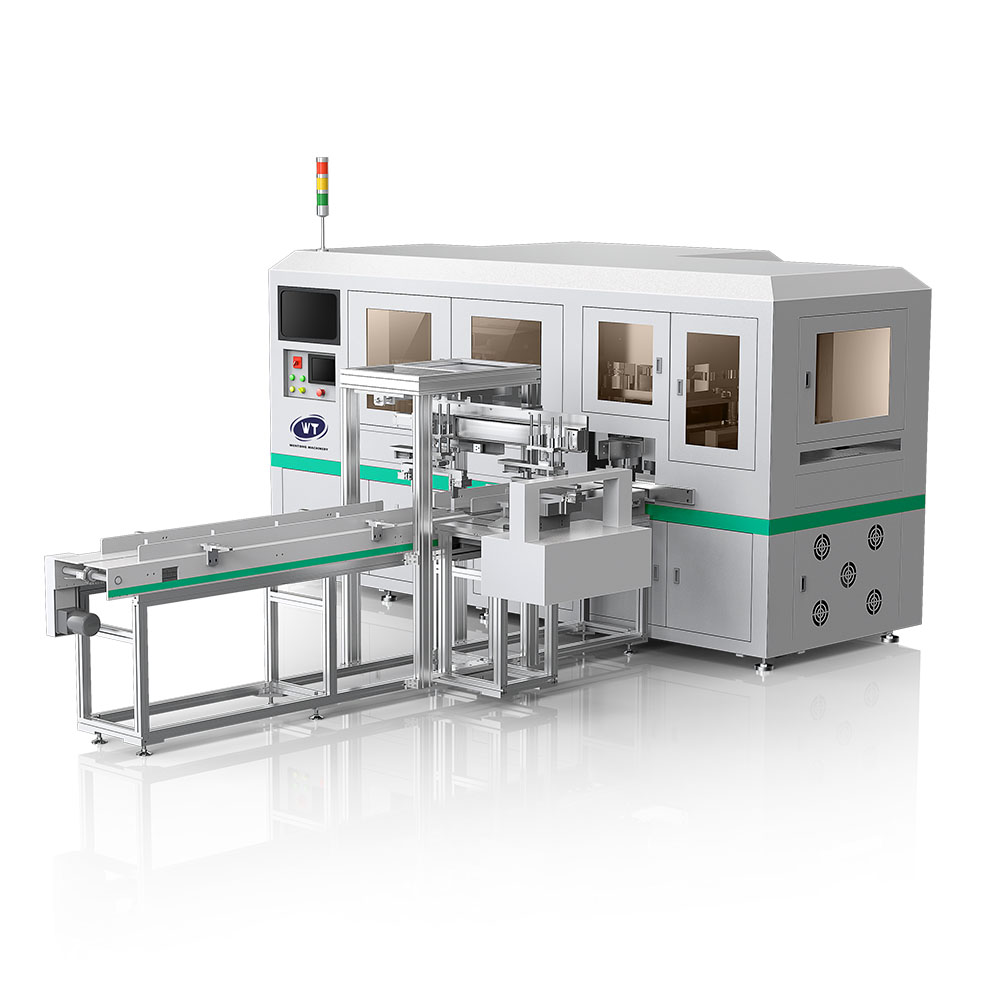

Cartoon card die-cutting machine

As the global trading card game market continues to grow, the main competitive advantage of card manufacturers lies in their ability to produce high-quality animation peripherals, high-end membership cards, and smart cards and the ability to produce products quickly, accurately and diversely. The anime card die-cutting machine breaks through the limitations of the traditional punching machine. Now it is a high-end automated production unit integrating precision die-cutting, multi-functional hot stamping, intelligent sorting and customised card collection. How does the cutting-edge animation card die-cutting machine reshape the card production line with mature technology, modular design, and data-based precision control to meet the high-standard production needs of various cards, from game cards and animation collection cards to bank cards and smart cards?

1. The main definition and use scenarios of the animation card die-cutting machine

The cartoon card die-cutting machine is a high-tech automatic machine specially designed for the final shape punching and surface treatment of card products. Its main work is to punch the printed large cards at one time through high-precision moulds, cut out the finished cards, and ensure that the edges are smooth and burr-free.

The equipment is especially suitable for mass production environments with extremely high requirements for the texture of the card edge, the consistency of the size, and the surface attachment process (such as hot stamping).

The main areas of application products are:

- Entertainment and culture: Trading cards include Yu-Gi-Oh!, Pokémon, Magic: The Gathering, anime character cards, celebrity cards, sports cards, etc.

- Games and entertainment supplies: playing cards, board game cards and dice cards are all games and entertainment supplies.

- Finance and identity recognition: bank cards, credit cards, membership cards, access cards, social security cards, etc. are all financial and identity recognition.

- Communication and intelligent carrier: SIM card and various intelligent IC cards

- Special printing: including high-end bookmarks, greeting cards, special-shaped filter paper, precision labels, etc.

This equipment is best suited for places where a large number of cards need to be made, and the edges of the cards need to be very smooth, the dimensions need to be very consistent, and the surface adhesion process (such as hot stamping) needs to be very good.

2. Accurate stamping and good texture are the key to no burrs on the edge.

High-end products first need the feel and appearance. Our animation card die-cutting machine adopts the following technologies to greatly improve the punching accuracy:

- Ultra-high rigidity integral frame: The heavy-duty steel structure is optimised by finite element analysis to ensure that the body deformation is minimal during long-term high-tonnage stamping cycles, providing a stable benchmark platform for each stamping.

- Precision guiding and transmission system: ultra-high precision ball guide rail, adjustable pre-tightening force, heavy-duty double toggle or four-bar linkage force increasing mechanism, making the mould closing process very smooth and accurate. The system also has an automatic 7.5 kW high-power servo drive system. The servo system can precisely control the pressure, position and speed so as to avoid impact and vibration.

- Professional-grade mould compatibility and adaptability: The equipment is compatible with high-precision moulds such as laser knife moulds and corrosion knife moulds. The precision flatness adjustment mechanism (which can usually control the flatness of the worktable within ±0.02 mm) ensures that the force on each point of the mould is consistent. Thus, the main purpose of “punching and cutting accurately without burrs” is achieved. The edges of the cards made by the equipment are smooth and flat, and there is no need to polish them again. This directly improves the quality of the product and makes the user feel better.

Key parameters include:

- Punching accuracy: ±0.05 mm

- Maximum die-cutting pressure: 2T-6T tonnes

- The flatness of the worktable should be within L2800*W1750*H1850MM.

- A 7.5 kW AC servo motor is the main drive motor.

Equipment for the global market needs to work at different speeds and intensity levels around the world. The durability of the equipment is directly related to the output and income of customers.

- Long-life design of core components: bearings, guide rails, lead screws, etc. are all from world-renowned brands. The central automatic lubrication system ensures that these components will not wear even at high speed and have a long service life.

- The control system is mature and stable: Based on an industrial PC or high-performance PLC, the algorithm has been tested by the market for many years. The interface supports multiple languages (Chinese, English, Spanish, etc.), with clear logic and a perfect self-diagnosis function. This makes it easier to use and less time-consuming to repair.

- Strict manufacturing and quality control standards: Each piece of equipment at the Shenzhen headquarters factory undergoes more than 36 hours of continuous no-load and load testing before leaving the factory. The real production environment is simulated to ensure that after delivery to the customer’s factory anywhere in the world, it can be quickly put into stable production.

4. Diversification of functions and increase of technology of cartoon card die-cutting machine

This cartoon card die-cutting machine has great functional scalability, which helps customers to obtain the maximum benefits from equipment investment.

- Wide range of material adaptability: The tool can be used for a variety of card materials, including cardboard, PVC and PETG. By changing the pressure and mould, it can also accurately punch books (exercise books, notebook covers and inner pages), industrial filter paper, composite materials, etc.

- Optional integrated hot foil stamping unit: The unit can be easily connected to the fully automatic hot foil stamping machine. The unit can control the hot foil stamping temperature (±1°C), pressure and time very precisely. It can also achieve multiple effects, such as ordinary hot foil stamping, texture hot foil stamping and holographic positioning hot foil stamping. Die cutting and surface decoration are performed simultaneously in one system, which speeds up the process, makes it more efficient and reduces registration errors.

5. Intelligent post-processing: automatic sorting, classification and collection

This feature is the difference between a modern animation card die-cutting machine and an old die-cutting machine. It directly meets the strict requirements of “version” and “classification” in the production of collection cards.

Optional: The automatic visual recognition and sorting system has a high-resolution industrial camera at the discharge end, which can quickly find the patterns, codes or specific marks printed on the card, such as rarity marks, series symbols, etc. The system sends different types of cards into different channels according to the set rules.

There are many ways to get a custom-made product, and they are very flexible:

- Sequential collection: After punching, the order of the cards is guaranteed to remain unchanged. This makes it easy to check against the previous printing process or to facilitate strict serial number management (such as serial number collection cards).

- Collect by category: Use the vision system above to stack different types of cards (such as common cards, rare cards, and flash cards) or put them into different finished product boxes. This allows sorting and production to be carried out at the same time, saving a lot of work for the next step.

- Efficient waste separation system: Automatic waste suction or mechanical waste removal system can easily sort and collect the waste frame after punching and the finished cards. This can keep the working area clean and make the finished products free of impurities.

6. Fully integrated animation card die-cutting machine personalised solution

We know that every production line is different in some way. We manufacture equipment, but we do more than just sell individual machines. We also offer customised, integrated solutions to meet our customers’ specific needs.

- Customised process flow: According to the specific process of the customer’s products (such as whether online hot stamping, UV varnishing, QR code printing, etc. are required), a plan is formulated on how the equipment is connected and how it works together.

- Die and fixture support: Full range of assistance from die design concepts to fixtures that help with things like special card holders and stackers.

- Open electrical and software interfaces: The equipment adopts standard communication protocols such as Modbus TCP/IP, which can be easily connected to the customer’s MES (Manufacturing Execution System) or factory Internet of Things, making production data easier to view and manage.

- Global technical service network: We have established technical service outlets or partners in major overseas markets to provide remote support, localised training, and rapid delivery of spare parts. This is due to our R&D and manufacturing centre in Shenzhen.

Summary

In short, this cartoon card die-cutting machine is oriented to the global market and is becoming an essential tool for global high-end card manufacturers to improve production capacity, quality and competitiveness. It has unique precision punching, durable and reliable quality, multi-functional flexibility, expandable hot stamping technology, mature and stable core technology, intelligent automatic classification and sorting collection capabilities, and highly flexible customised solutions. It not only completes the punching process but also makes the entire card post-press production process a better intelligent workstation. Choosing it means choosing an efficient, high-quality and flexible card-making method.