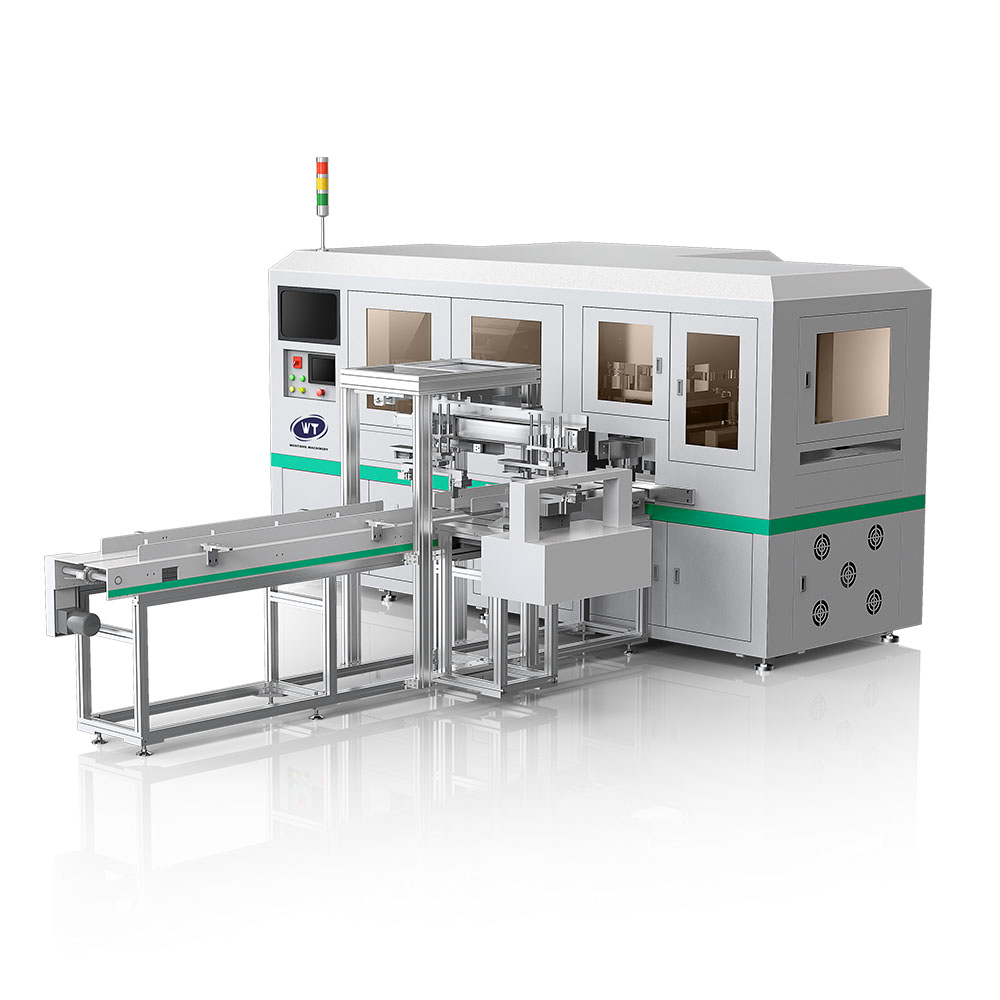

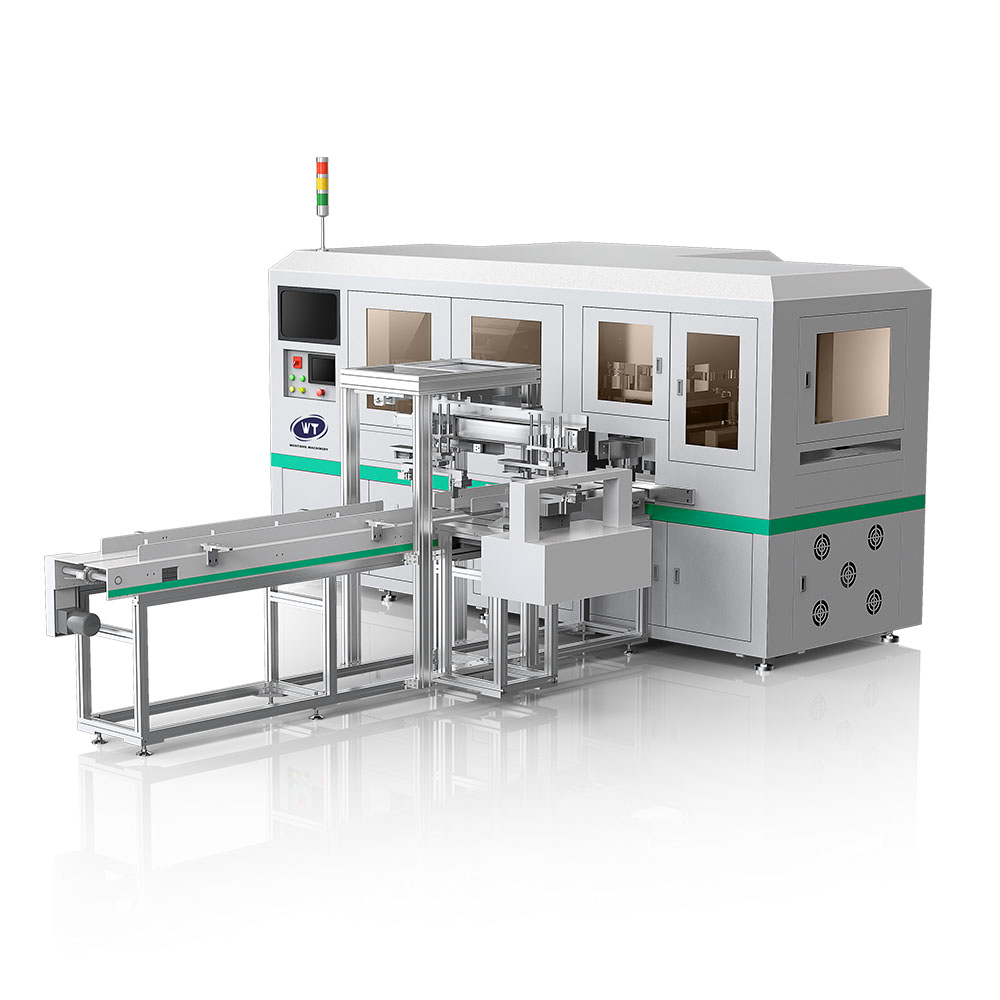

In the modern card product manufacturing industry, the edge precision, texture and production efficiency of the final product directly affect its competitiveness in the market. These include basic membership cards, access cards, high-end smart chip cards, financial payment cards, and various game cards and collection cards. Our company is located in Shenzhen, China, and our main goal is to sell high-performance industrial manufacturing equipment to customers all over the world. The professional PVC card die-cutting machine released this time is the main equipment created to meet the high-end and automated production needs. This machine is not only a punching tool but also a complete production unit integrating precision die cutting, automatic sorting and intelligent card collection.

The main function of this machine is to punch the laminated PVC card material into shape quickly and accurately. Its design is based on a wealth of industry experience and mature technology to ensure that production always produces high-quality finished products. The following is a list of its most important functional features:

Excellent punching accuracy and edge quality:

The equipment adopts a high-rigidity integral frame and precision guiding system, which will not shake during punching and has high punching accuracy and a good edge effect. The punching accuracy can reach ±0.1 mm with special high-hardness alloy dies. The common process problems such as edge burrs, wire drawing, and delamination are completely solved. The card edges are smooth and flat, and the touch is smooth. This directly improves the overall texture and high-end feel of the card and meets the requirements of products such as ID cards and bank cards that have very high requirements for edge quality.

Wide range of applications:

This machine is called a PVC card punching machine, but its powerful punching system makes it not only punch PVC cards. It can adapt to a variety of card-base materials, such as PVC, PET, ABS, and paper composite materials with different thicknesses and hardness. In addition, by changing the mould, the machine can easily switch to the punching of products such as book lining boards, special filter paper, and leather sheets. This allows the machine to play its maximum role and provides manufacturers with more choices when planning production.

Integrated hot stamping process interface, mature system integration:

the equipment has a standard interface, which can be easily connected with the fully automatic hot stamping unit. That is, different hot stamping effects, such as gold, silver and laser, can be achieved before and after die cutting. This allows die-cutting and decoration to be completed in one go, shortening the time to complete semi-finished products, improving production efficiency and reducing losses. The whole system is technically mature, the running logic is stable, and the failure rate is low.

Fully automatic sorting and collecting system:

This is the most prominent feature of the machine, which is better than ordinary die-cutting machines. The machine is equipped with a high-sensitivity visual recognition or mechanical induction system. The system can automatically sort and group the finished products after die-cutting according to the pre-set program. For example, cards with different patterns, different batches, and different grades can be automatically distinguished.

Sequential collection:

This helps to keep the serial number order of cards, such as scratch cards and lottery tickets. This way, they are made in the same order as they are cut.

Sorting by category:

It can automatically sort good and bad products into different collection bins. It can also collect different kinds of cards, such as game cards of different characters. This saves a lot of time and money that would otherwise be spent on manually sorting things out later, and it also prevents things from getting mixed up.

High automation and powerful core:

The equipment adopts a high-power 7.5 kW high-response servo drive system, which is stable, powerful and accurate. Servo control ensures that the punching stroke, speed, and pressure are just right for each material. The whole process is basically automated, and only a small amount of manual feeding and care is required. This not only reduces the labour intensity but also ensures the safety of production.

Part 2: Production and industry problems solved by the PVC card die-cutting machine

These are the problems that card manufacturers around the world often encounter as they strive to improve production capacity and quality, and this PVC card die-cutting machine is manufactured to solve these problems:

The machine uses high-precision punching to ensure that the product has no burrs. This makes the product reliable and gives it a high-end appearance.

Solve the problem of slow and error-prone manual sorting: When a large number of different types of items need to be sorted, such as anime cards or game cards, or when it is necessary to distinguish between good and bad products, manual sorting is slow and error-prone. The automatic sorting and classification function frees people from repetitive labour. The sorting accuracy rate is almost 100%, and the packaging and delivery speed is much faster.

Small batch, multi-variety production, line change problem: The equipment can quickly switch from producing PVC bank cards to producing paper bookmarks or special filter paper because it has a quick mould change design and can handle various materials. This means the machine doesn’t have to sit idle for long periods, making it ideal for factories that take on a large number of different types of orders.

Solving the problem of scattered production process chains: The machine combines the hot stamping interface with a customised collection solution to integrate multiple independent post-processing procedures. It provides a complete customised solution from semi-finished products to finished products, which can be packaged immediately. This makes production management easier and speeds up delivery.

Longer service life and lower maintenance costs: The equipment needs to be very durable in order to operate continuously at high intensity levels. The most important parts of the machine are made of strong alloys and treated with special processes. The main gearbox system is durable and requires little maintenance, which means lower running costs over time.

Part 3: Production effect and humanised operation

Easier to use: The friendly human-machine interface (HMI) centrally controls all parameters, and the settings of punching mode, sorting rules, collection method, etc. are clear at a glance. People who have never done it can quickly learn it with a little training.

Production visualisation management: The control system displays information such as the production quantity, production speed, and qualification rate in real time. It can also provide self-diagnosis prompts for faults to help managers better understand the production situation.

Better working conditions: Automation makes the stamping process safer because it frees people from the stamping process. The machine runs well, with no great noise or vibration.

Comprehensive improvement of benefits: high-speed automated production directly increases the average daily production capacity on the premise of ensuring quality. Automatic sorting reduces the number of sorting workers and reduces labour costs. Reducing waste means more materials. When these things work together, they can help people make better products.

Part 4: Application scenarios and industry applicability of PVC card die-cutting machines

This PVC card die-cutting machine is exquisitely designed, easy to operate, suitable for making card products and precision sheets, and widely used. Main applicable situations:

Financial security card industry production: a large number of high-quality bank cards, credit cards, social security cards, ID cards and other cards. The requirements for edge precision and cleanliness are very high.

Smart card and electronic label industry: used for punching and cutting various smart cards, access cards, traffic cards, RFID labels and other base materials. If the punching is done properly, the internal antenna will not be damaged.

Game and cultural and creative product industry: Quickly and conveniently produce playing cards, collectible game cards (such as Yu-Gi-Oh, Pokémon cards), animation collection cards, etc. The automatic sorting function is very suitable for sorting and making cards of different styles at the same time.

Commercial and membership service industry: Hot stamping technology can be used to improve the quality of various cards such as hotel room cards, membership cards, VIP cards, and gift cards.

Speciality paper and industrial parts: Die-cut hardback liners for high-end books, filter paper for precision filtration equipment, and small leather or soft composite parts. This shows that it can be used for many different things.

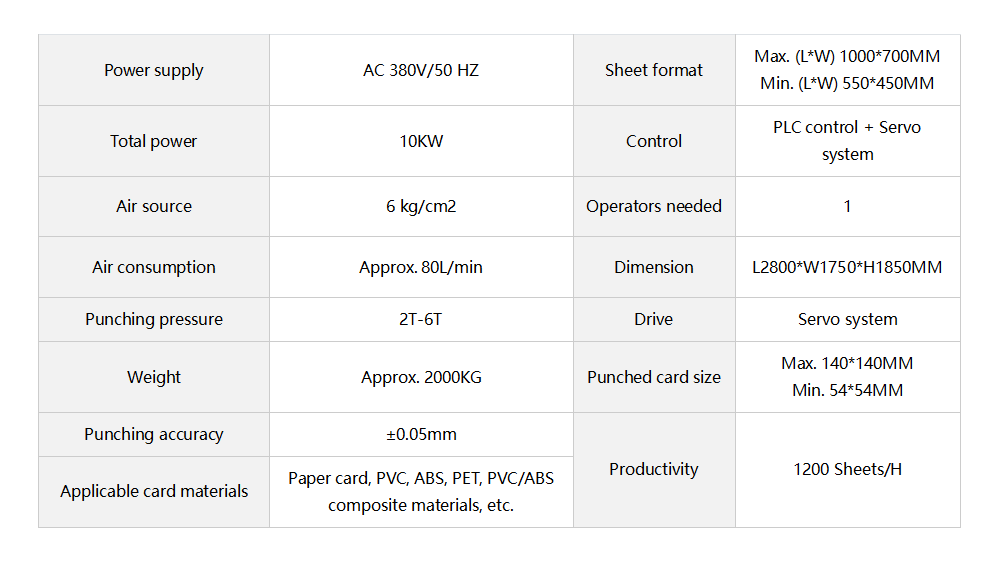

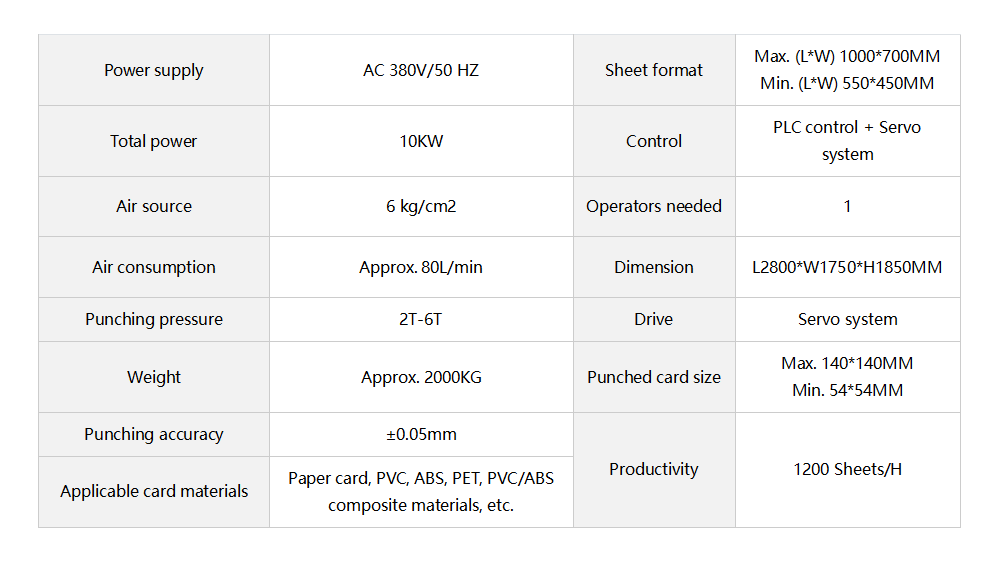

PVC card die-cutting machine parameters

This PVC card punching machine is not only production equipment but also a strategic tool to help global card-making enterprises improve quality, efficiency and competitiveness. It has the characteristics of high-precision punching, automatic sorting and multi-process integration. It meets the main needs of the market for automation, intelligence and flexible production and is a good choice for future production.