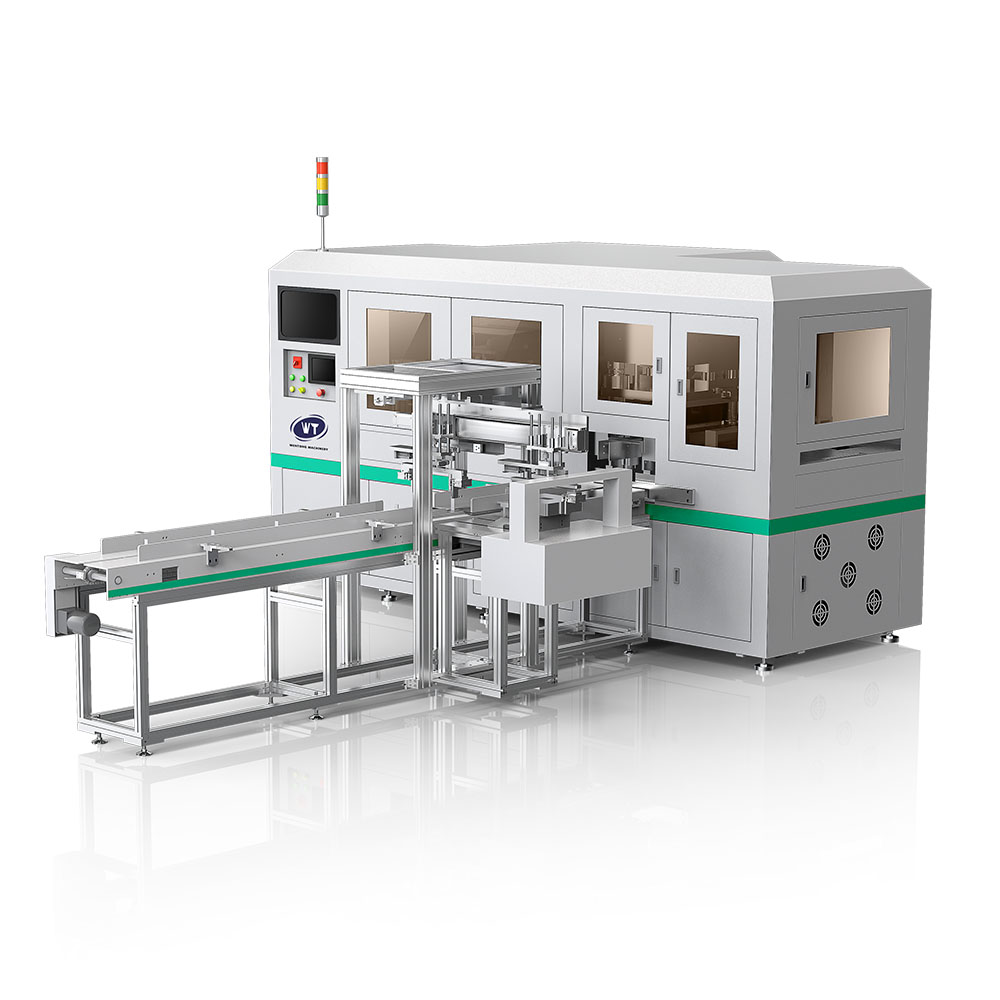

Game card die-cutting machine

1. Problems and Solutions of Modern Card Making

The global card industry is undergoing a major transformation. The market for trading card games (TCG), smart ID cards, high-end collectable cards, and functional cards is expanding. This means that the production process needs to be more flexible, with more card types, smaller batches, and faster delivery speeds. At the same time, the standards for production accuracy, consistency, and traceability are also constantly improving. The traditional manufacturing method mainly has three problems:

- Low efficiency of order change: It takes several hours to change the mould and adjust the parameters, which is difficult to keep up with the product changes.

- The “honest” process: sorting, classifying, counting and other work are all done manually, which is costly, time-consuming and difficult to count.

- Quality issues: For example, there may be differences in size or edge quality that are difficult to distinguish with the naked eye between different batches or even the same batch of products.

We have manufactured a new generation of game card die-cutting machine in Shenzhen, which is a world leader in manufacturing technology. It was developed in response to the pain points of the industry. This machine is not only a high-precision punching machine but also a complete production solution, including intelligent visual recognition, automatic sorting and classification, and a fast order change system. It will turn separate steps into a single, intelligent, digital production process, thereby completely changing the way cards are made.

2.1 Precision stamping and pressure control module

The super-stable punching unit is the most important part of the equipment. We abandoned the traditional mechanical transmission mode and changed to the automatic 7.5 kW servo motor as the main driving force. The servo system has a fast response speed and strong closed-loop control ability, which is the embodiment of its superiority.

Precise pressure control: The pressure can be precisely set within the range of 0-300 kN and can be adjusted steplessly. The sensor provides real-time feedback to ensure that each card, whether it is a 0.2 mm thin paper card or a 1.2 mm thick composite card, can get the appropriate punching force. Directly achieve precise punching without burrs; the cut is as smooth as a mirror, giving the card an excellent, unique feel and texture.

Dynamic stroke adjustment: The programme controls the punch movement curve (such as fast forward-slow cut-fast backwards), and the no-load speed is set to the highest on the premise of ensuring the punching quality. The theoretical maximum punching speed is increased to 12,000 times per hour.

2.2 Intelligent Visual Recognition and Automatic Sorting and Classification System

The system is an important step towards intelligent production of “Industry 4.0”. It has high-resolution line array and area array cameras, a dedicated light source system, and an industrial control mechanism for rapid image processing.

- Working principle: After the card is punched, it directly enters the high-speed camera area. The system takes photos of the card in milliseconds and compares them with the pre-set template library. The basis for comparison can be:

- Pattern features: Distinguish different card surface designs.

- Colour information: Look for special versions, such as flashcards and cards in different colours.

- Code recognition: Read QR codes, serial numbers or invisible UV codes.

- Sorting execution: The identification results are sent to the high-speed electromagnetic sorting valve in real time. The cards are then directed to the correct collection channel by air flow or mechanical action. Standard systems can sort 2-4 channels simultaneously, and integrated, customised overall solutions can increase to a maximum of 8 channels or more.

Core value: This function can realise the sorting and fully automatic collection. For example, when making a set of game cards, including ordinary cards, rare cards, flash gold cards, etc., the equipment can sort them when outputting, and the accuracy rate is more than 99.95%. It prepares for the next step of automatic packaging and pairing, saving more than 80% of the workload in the next step.

2.3 Quick Changeover and Flexible Production System

To meet the market demand for “small batch, multiple batches”, we have made revolutionary changes in the ease of use and flexibility of the equipment.

- Quick mould change device: adopts European standard modular mould interface and pneumatic locking system. The operator does not need a lot of tools, and the core mould can be replaced in 3-5 minutes. For product lines that are used more often, a set of pre-installed mould components can be added so that the fastest changeover time can reach 2 minutes.

- Digital recipe management: All process parameters (pressure, stroke, speed, sorting logic, collection method) can be set on the human-machine interface (HMI) and saved as “product recipes”. When switching products, simply call up the corresponding recipe from the database. Most settings are automatically loaded and the system is automatically calibrated. This avoids the problems caused by the old method of debugging relying on the experience of the old master. It also ensures the maturity and consistency of production standardisation in technology.

2.4 Various Finished Product Collection and Stacking Schemes

The collection unit is the end of the production process and the beginning of the packaging machine. We have many different ways for you to choose the finished product:

- Collection in order: For items with strong seriality, such as numbered collection cards and complete sets of banknotes, the system strictly stacks them in the order of production to ensure the integrity of each set of products.

- Multi-channel sorting and collection: Each sorting outlet is connected to a collection stacking position through an automatic sorting system. The stacking height and counting quantity can be set in advance. When the set value is reached, the system will automatically prompt or change the box.

- Extended interface: The collection end is equipped with a conveyor belt that can be directly connected to the automatic boxing machine, plastic sealing machine, and strapping machine to realise a true end-to-end unmanned production line.

2.5 Process expansion capability: hot stamping, multi-material

The design of the device platform has the potential to be used in a variety of different ways in the future.

- Online hot stamping: A precision hot stamping unit can be added to the machine to realise synchronous punching and hot stamping. The hot stamping position accuracy can reach ±0.1 mm, and the applicable range of electro-aluminium foil materials is wide. This not only makes the card look more beautiful and more difficult to counterfeit but also makes the whole process more efficient and increases the output by speeding up the process.

- Material versatility: With powerful servo pressure control, the machine can perfectly handle all kinds of cardboard, PVC and PETG cards. By changing the parameters and moulds, it can also be used for other tasks, such as stamping and cutting books and filter paper. This means that one machine can do many things, giving you the most return on your investment.

3. Technical specifications and configuration of the game card die-cutting machine

| Power supply |

AC 380V/50 HZ |

Sheet format |

Max. (L*W) 1000*700MM

Min. (L*W) 550*450MM |

| Total power |

10KW |

Control |

PLC control + Servo system |

| Air source |

6 kg/cm2 |

Operators needed |

1 |

| Air consumption |

Approx. 80L/min |

Dimension |

L2800*W1750*H1850MM |

| Punching pressure |

2T-6T |

Drive |

Servo system |

| Weight |

Approx. 2000KG |

Punched card size |

Max. 140*140MM

Min. 54*54MM |

| Punching accuracy |

±0.05mm |

Productivity |

1200 Sheets/H |

| Applicable card materials |

Paper card, PVC, ABS, PET, PVC/ABS composite materials, etc. |

4. Safety and value for the world market

We know that equipment exported to other countries must meet the highest standards of safety, stability and ease of maintenance.

- Reliability design: All main components (servo motor, PLC, sensor, guide rail) are international top brands, ensuring stable spare parts support anywhere in the world. The average fault-free time (MTBF) of the whole machine design is more than 2000 hours.

- Safety: The equipment meets the CE safety standards and has a fully enclosed protective cover, a grating safety area, a two-hand start button, and an emergency stop device to ensure the safety of the operator.

- Localisation service: The Shenzhen headquarters has a complete spare parts warehouse and has established a technical service network covering the world’s major markets. We provide full life cycle services, including installation, commissioning, operation training, remote technical support, etc., to ensure your production never stops.

5. Conclusion

In the increasingly competitive global card and card manufacturing market, the key to winning is the right balance between speed, adaptability and high quality. Our game card die-cutting machine is born for this. The revolutionary automatic sorting and distribution system makes the slow and arduous manual post-processing completely automated. The intelligent quick-change design reduces the production switching time to the extreme, making flexible manufacturing a reality.

It is not just a device but a personalised overall solution. We can help you set up the equipment so that it can be perfectly integrated into your production system and become your most reliable partner in improving your core competitiveness and meeting the challenges of the future market. We can provide you with specific configuration recommendations and process support based on your materials, product design and production capacity goals.