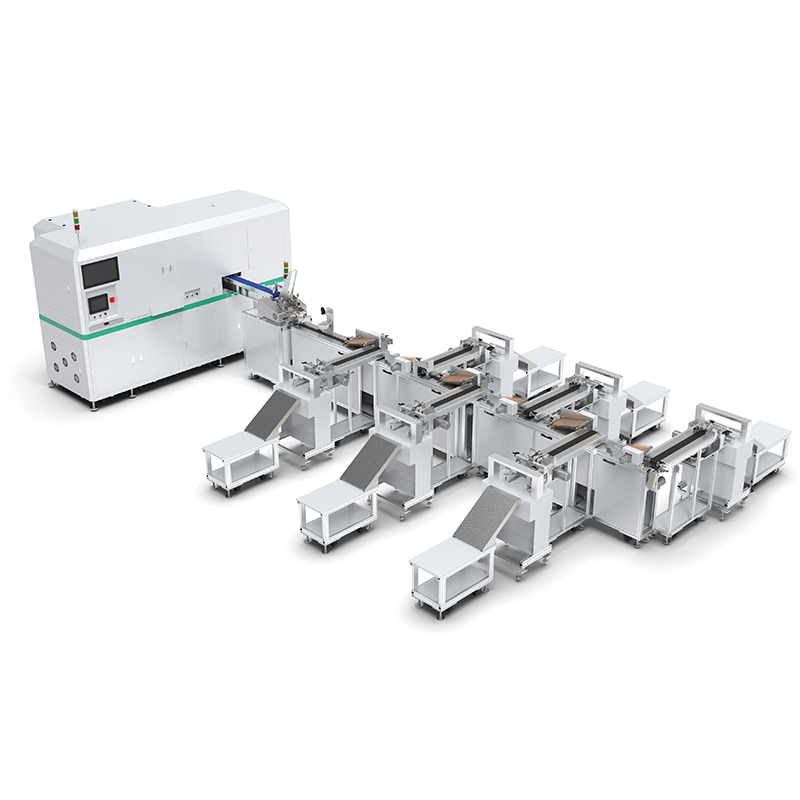

In the global business card printing industry, competition has surpassed the efficiency of just looking at things. The company is now also paying attention to how accurate their products are, with complex processes and flexible production. And how intelligent their backend processing is. Manufacturers are always told to do better, deliver products to customers faster, and reduce costs. This applies to smart chip cards that protect the security of your funds and collectible game cards that look and feel great, as well as membership and game cards that are always in high demand. Shenzhen Wentong Machinery is very familiar with the changes in this business over the years. They have successfully manufactured and released a fully automatic punching machine that can accurately classify and categorize items, with a wide range of applications. This device is not only a better version of traditional die-cutting machines; it is a complete solution platform that will change the way things are manufactured, allowing you to go from raw materials to finished products in one place. It is designed specifically for modern manufacturing companies that sell high-end products around the world.

1. The core functions and modern production of card punching machines

The concept behind the design of this device is to make the end product as good as possible and the manufacturing process as efficient as possible. The main technical value is displayed in a systematic manner through the following functional modules:

Micron-level precision and excellent finished product texture guarantee:

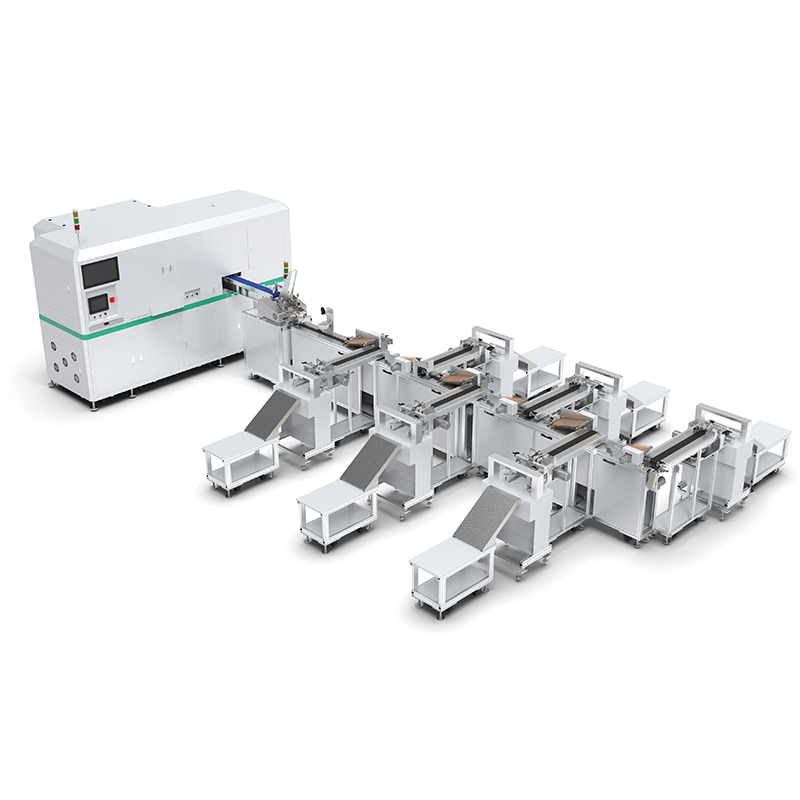

This device is built on the concept of perfect accuracy, which means it can measure within micrometers and ensure high-quality finished products. The high-stiffness frame optimized through finite element analysis, as well as the pre-tensioned precision ball guide rail, ensures that the stamping process does not bend or vibrate. The automated 7.5 kW servo system in the drive core allows you to control power and response speed in amazing ways. By using alloy steel molds that have undergone special heat treatment and grinding, we can achieve long-term stable stamping accuracy of ± 0.05 mm. The absence of burrs and smooth edges that look like mirrors are indicators of this level of precision. PVC、PET、ABS, Even more advanced paper-based materials can have sharp or rounded corners. This makes the card feel more professional and easier to hold, making it look like a high-end product.

Durable architecture designed for continuous production:

A reliable architecture built for continuous production: Reliability is the key to production capacity. All important moving parts that support weight are made of high-quality cast iron and a special type of alloy steel. They have also undergone high-precision machining and hardening. There is an automatic lubrication system in the middle of the device, which can maintain good shape even if important parts run at high speed for a long time. The mean time between failures (MTBF) is much higher than the industry average, making it easy to handle continuous 24-hour production tasks. Customers can be confident that their investment is worthwhile in the long run, as the plan lasts for over a decade.

Multifunctional application extension of card punching machine (one machine for multiple purposes):

This platform is suitable for various processes and can help customers make full use of their equipment. It can perfectly punch various cards and also do other things such as cutting books, making precise industrial filter paper, and die-cutting electronic insulation materials. It achieves this by quickly changing molds and modifying program settings. This versatile design gives the production line a great deal of freedom. It enables businesses to quickly respond to various market orders and maximize the production capacity of individual devices.

Online integrated hot stamping process unit:

This machine can easily add high-precision hot stamping modules to meet the high-end card decoration needs. This module has its own servo drive, which can be stamped when it is cold or hot. The position of hot stamping is accurate to within ± 0.1 mm. By placing the stamping and hot stamping processes on a machine that can run continuously, you can eliminate all registration errors and losses that occur when using conventional machines. This not only accelerates the speed of these composite processes, which can produce up to 10000 sheets of paper per hour, but also ensures that decorative effects such as embossed logos on bank cards and patterns on luxury membership cards remain unchanged.

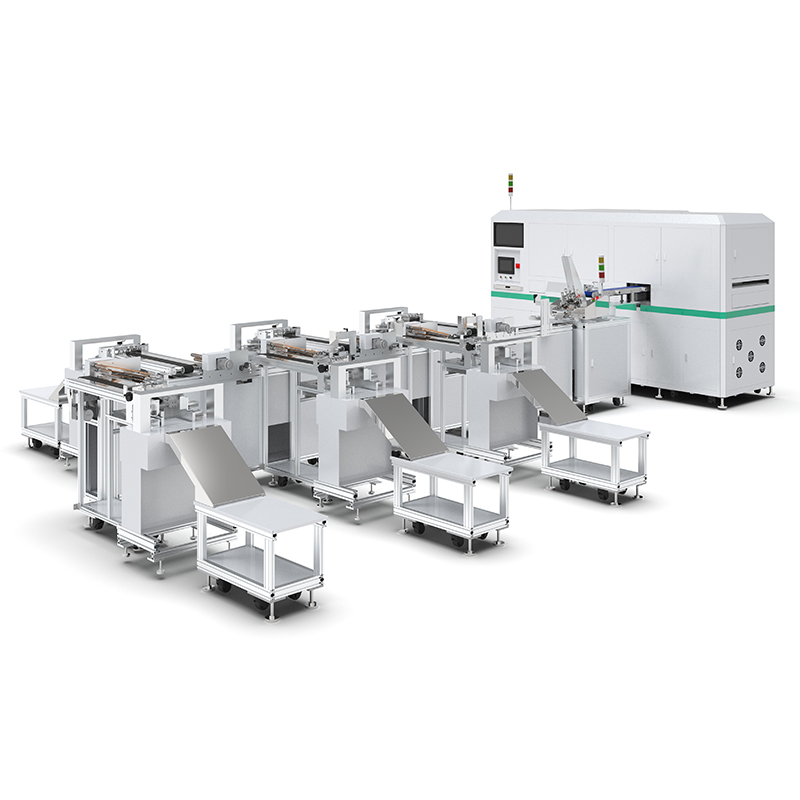

Intelligent classification and sorting system:

What sets this device apart in the industry is its revolutionary intelligent classification and sorting system. The system has a high-speed industrial vision camera or RFID reader that can read the text code, pattern, color, or data embedded in the chip on each card in real time. The high-speed servo-driven sorting system performs precise tasks after processing information, resulting in two main modes:

- Collecting in order: It is important to maintain the production serial number order of tickets, certificates, serialized gift cards, and other similar items. This ensures that information about production and logistics is completely identical.

- Collect by Category: Automatically send different patterns (such as anime characters), levels (such as rarity of game cards), models (such as smart card types), or qualified/unqualified products to the collection channel you set up.

This automatic sorting and classification feature eliminates the need for manual and error-prone work in the next step. This is an important step towards achieving production completion in an intelligent manner.

Deep customized integrated solutions: We understand that each factory has its own needs and production environment. We provide complete and integrated customized solutions, including everything from device infrastructure platforms to ways to collect different products from each customer. Our engineers can collaborate with customers to manufacture unique collection hoppers, connect interfaces to automatic packaging machines, and use feeding systems with non-standard-size materials. This ensures that the equipment is fully compatible with the production line already in place and solves some problems in production.

2. Competitive advantage analysis of automated card punching machine

This fully automatic sorting and card-punching machine is better than other machines on the market. It not only has the best individual parameters but also makes the entire system work better.

This machine can do everything by itself, from feeding to cutting to receiving. It has increased production efficiency by over 200% and eliminated all safety and quality issues caused by manual operations. This product meets transportation standards and does not require any additional processing, as it has precise stamping and no burrs.

The built-in intelligent classification and sorting system sets this machine apart from other fully automatic clock-in machines. Although conventional machines make stamping and cutting more automated, finished products are often mixed and sent out, which means a lot of manual sorting, counting, and packaging work is required. This machine can reduce the workload required to complete tasks by 70% from manufacturing to “classification ready.” Sorting is almost perfect, solving the long-standing problems of board confusion and installation errors in the industry. The automatic 7.5 kW servo system also uses less power and responds faster to changes. This helps save a lot of energy and makes long-term large-scale production more stable.

In addition, due to its flexible platform design and ability to be used in conjunction with hot stamping technology, this equipment provides a “one-stop” solution for many process needs of customers. This flexibility makes production easier to operate, as it reduces the cost of purchasing multiple single-function devices and frees up factory space. What ultimately makes us competitive is that we can provide our customers with more than just one machine. We can provide them with customized solutions. We also provide a production system to ensure stable production, smooth operation, and keeping up with the times.

3、 User experience of automated classification card punching machine

Every department of the enterprise has felt the value brought by this device:

The multi-touch human-machine interface (HMI) is easy to use and learn, making it easier for on-site operators to learn and use the system. You can use the mold quick-change mechanism to replace the product within 15 minutes. Low noise design and full safety features such as grilles, emergency stops, and interlocks ensure a safe and comfortable workplace. The intelligent sorting function eliminates the boring and repetitive work of sorting cards and provides more important tasks such as checking equipment, sampling quality, and viewing data. This makes work more interesting and beneficial.

The built-in Industrial Internet of Things (IIoT) module of this device is an excellent tool for production and operations managers who want to operate their business more efficiently. A dashboard that displays all content in real-time can easily show production volume, equipment operating conditions (OEE), how much energy is used, and any possible fault warnings. These numbers are a good starting point for developing better production and maintenance plans and finding places with limited production capacity. You can directly connect the customized finished product collection method to the downstream automated packaging line. This makes a part of the assembly line truly ‘unmanned,’ thereby accelerating the delivery cycle of orders and making it easier for customers to contact you.

The device has an extremely low failure rate and high durability, which means that maintenance costs are very low and production is always stable. This directly protects investment in production capacity. Enterprises can accept higher-value orders and be more competitive in the market because they can be used in multiple different ways. This device is based on comprehensive calculations aimed at improving efficiency, saving labor, reducing waste rates, and lowering energy usage. This is a confident decision to raise funds.

4、 Practical case of automatic card punching machine

Many of the best companies in the world have stated that this device works very well:

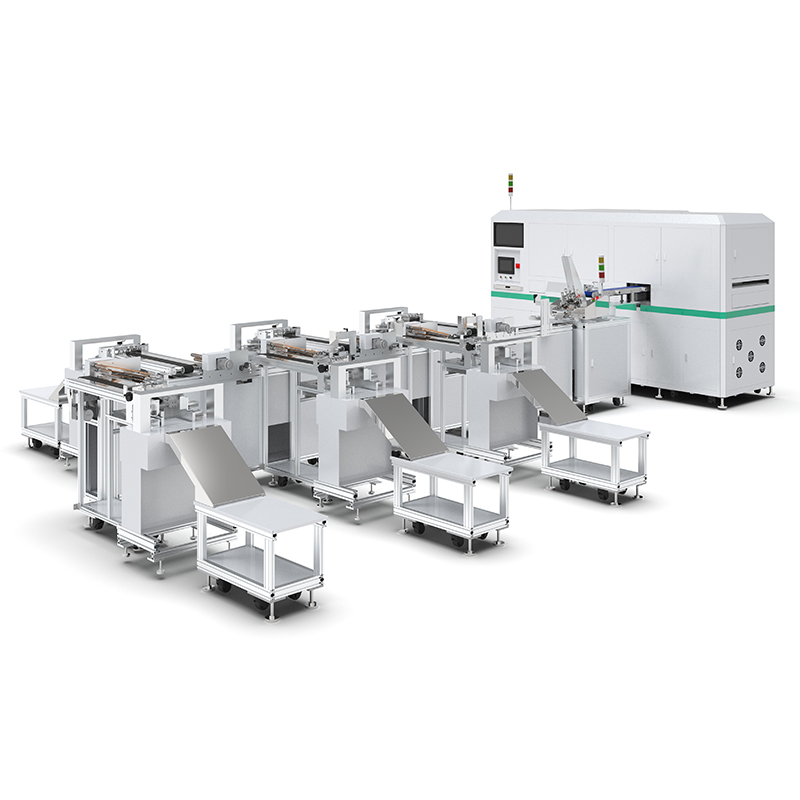

After manufacturing different types of multi-chip cards, a European company that manufactures security cards for many government agencies encountered problems with low sorting efficiency and difficulty in managing serial numbers. By using our equipment and adding RFID reading and sequential collection functions, the production line can read chip information and automatically classify it during stamping and cutting. This has increased production efficiency by 35%, which means there are no mixing errors when manufacturing millions of sheets of paper. It also fully complies with strict safety and traceability requirements.

A company operating in the global collectible card market is facing enormous pressure in Asia to manually organize a large number of cards, each with a different job. We have developed an automated system that uses high-resolution visual recognition to sort and classify things. It can classify dozens of different patterns at a rate of over 600 per minute and send them to up to 12 different collection bins. This means it can perfectly complete the work of dozens of people and ensure timely and correct delivery of products during busy sales hours, which is very helpful for the business.

A high-end industrial filter material supplier in North America needs to punch special filter paper into complex shapes. The edges must be very sturdy. With the precise pressure control, multi-purpose functionality, and customized mold solution of this device, we are able to perform precision stamping without dust or burrs. The product yield has increased from 85% to 99.5%, which helps it enter the fiercely competitive aerospace supply chain.

In short, Shenzhen Wentong Machinery’s fully automatic sorting and punching machine is the most advanced example of intelligent and integrated development in the fields of card die-cutting and precision stamping. It solves some specific production problems and creates a future of higher efficiency, lower costs, and stronger competitiveness for manufacturers around the world. It achieves this by combining high-quality mechanical precision, adaptable processes, and intelligent data-driven sorting. We hope to make the global business card printing industry better and more unique by working closely with customers and always using new technologies.