1. Application field of star card die cutting machine

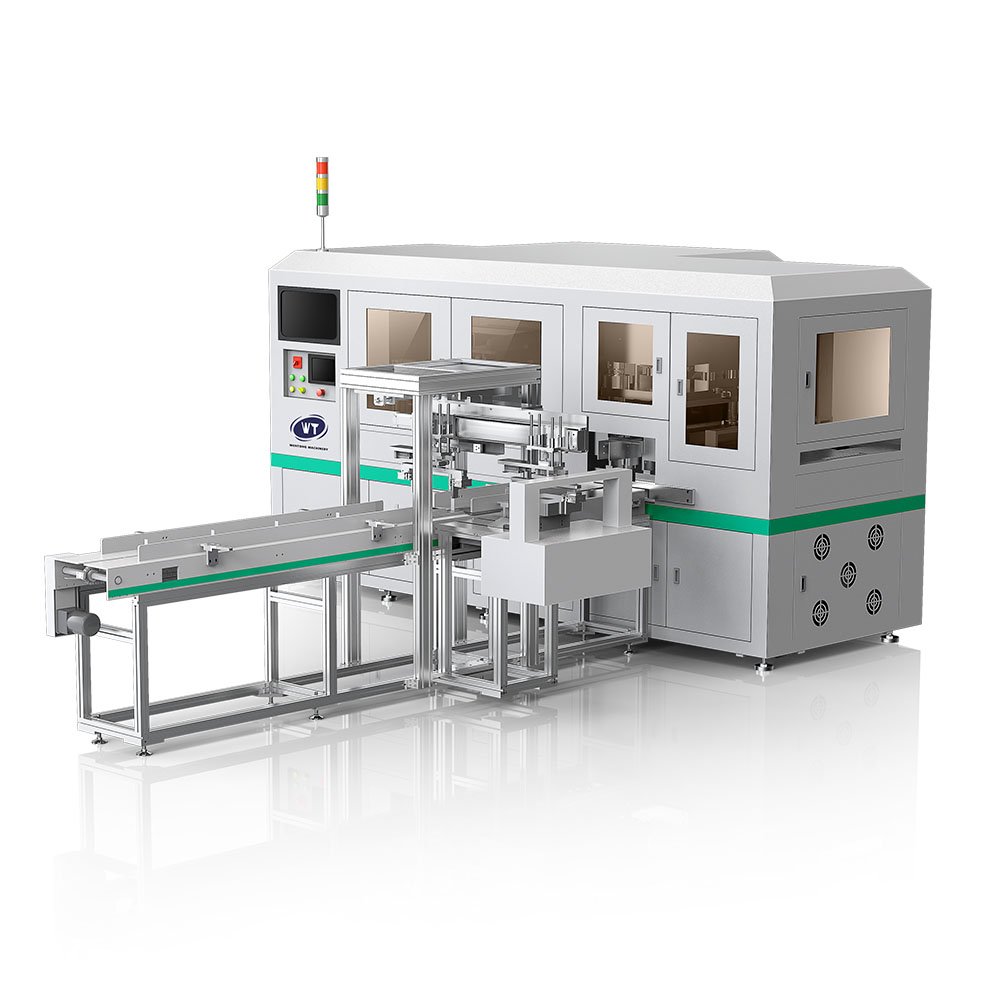

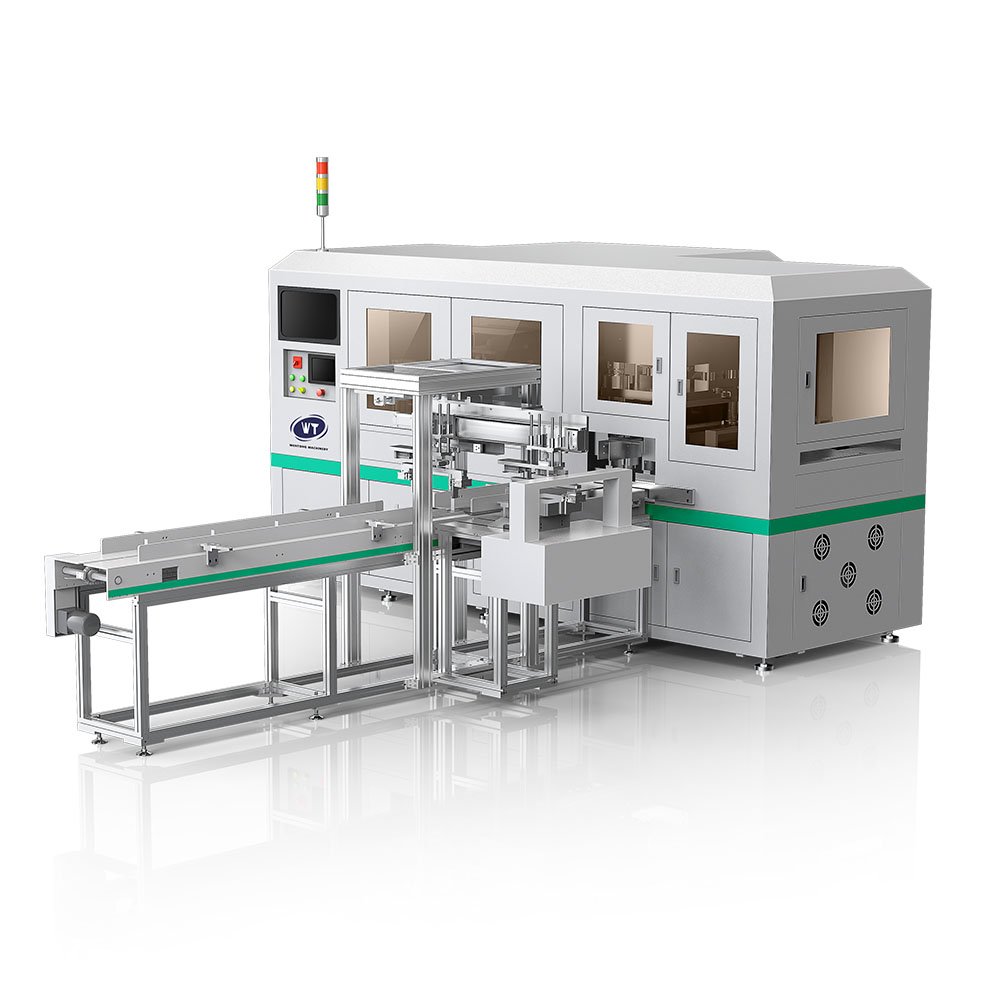

The Star Card Die-Cutting Machine is a professional-grade automated production equipment designed for the production of various high-precision and high-requirement card products. Its main job is to perform accurate, fast, and burr-free die-cutting operations. It also has an advanced automatic classification and sorting system built in to meet the strict standards of efficiency, quality, and flexibility of the modern card-making industry. The equipment is widely used in the mass standardized production of the following cards:

- Collectibles and entertainment cards: This is the main use of the device. There are many types of cards, such as sports star cards, animation collection cards, film and television character cards, Magic: The Gathering, Yu-Gi-Oh!, and Pokémon trading card game cards. These products require very precise pattern positioning, smooth edge cutting, and batch consistency. Any burrs or other issues would greatly reduce their value as collectibles and sales items.

- Smart security card: It can quickly produce chip carriers for various smart cards such as bank cards, credit cards, membership cards, access cards, and social security cards. The equipment can ensure the accurate cutting of the chip module window, the perfect fit between the card and the chip, and meeting the physical standards of financial-grade security products.

- Business and daily use cards: including playing cards, game prop cards, scratch cards, telephone cards, gift cards, hotel room cards, etc. The equipment is good at making a large number of items quickly, and the automatic sorting system can easily collect the finished products in the correct order (such as the order of poker suits) or according to the set classification.

- Special materials and composite process cards: After the equipment is adaptively transformed, it can die-cut special card materials such as PVC, PET, metal composite, and laser materials. At the same time, it can be perfectly matched with surface decoration processes such as hot stamping, screen printing, and UV to realize online or offline operations.

- Extended applications: The equipment can be used not only for die cutting. With its powerful die-cutting capacity and flexible die system, it can also be used for cutting book covers and precision die-cutting of industrial filter paper with extremely high precision requirements. This means that one machine can be used for multiple purposes, improving the overall utilization rate of the equipment.

The Star Card die-cutting machine is not just a simple stamping tool but a “one-stop customized overall solution” that integrates intelligent logic judgment, servo control technology, and precision machinery manufacturing. The design concept is based on “short, flat, and fast,” that is, a short production cycle, stable operation, and fast delivery. This is reflected in the following ten core features:

1. The punching and cutting is accurate and without burrs, giving the product a unique texture.

The equipment adopts a high-rigidity integral frame and a precision guiding mechanism to ensure the complete stability of the stamping process. The special alloy steel die-cutting knife board can be cut off cleanly and neatly at one time even under a stable pressure of up to hundreds of kilonewtons. The incision is smooth and neat, and there is no fluffing, powdering, or delamination. This feature is the fundamental reason for the high-end feel and appearance of the finished card, and it is also the main physical sign of high-end cards and ordinary printed matter.

2. Very robust and reliable in use

The main structural parts are made of high-strength cast iron or steel and are treated to eliminate internal stress. This ensures that the geometric accuracy of the equipment remains unchanged during long-term high-frequency operation (such as tens of thousands of strokes per hour). The key kinematic pairs adopt non-wearing bushings or linear guides, and the lubrication system is perfect. This means that the equipment can maintain its accuracy for many years, and the failure rate is extremely low in a continuous production environment, which greatly reduces maintenance costs and downtime.

3. A versatile machine

The equipment can quickly switch between different tasks by changing the die-cutting plate and adjusting the platform. For example, in the morning, the machine can die-cut game cards, and in the afternoon, it can be switched to punching standard-sized bank cards or special-shaped bookmarks. This flexibility is undoubtedly a great boon for processing centers that accept small-batch, multi-variety orders and printing and packaging companies with a wide variety of products.

4. Compatible with mature and stable hot stamping technology

The equipment is designed with consideration of how post-press processes work together. Thanks to its very precise step positioning accuracy (up to ±0.1 mm) and smooth transfer system, it can be perfectly connected or integrated with the hot stamping unit. Whether cutting before hot stamping or hot stamping before cutting, the perfect alignment of the hot stamping pattern with the outer contour of the card and the internal window can be guaranteed. This will make the product more valuable.

5. Well-developed and well-run technology

The whole machine control system adopts industrial PLC and a high-resolution encoder. The algorithm has been tested by the market for a long time. From paper feeding, positioning, cutting, and waste removal to material collection, the control logic of each step has been highly optimized, and the production rhythm is smooth and stable. The waste rate is kept at a very low level (usually less than 0.1%).

6. Complete integrated solutions to meet your needs

We not only sell standard mainframes but also customize solutions for the entire process, from the feeding system and die-cutting unit to the waste removal device and finished product collection. These solutions are based on the customer’s specific raw materials (rolls or single sheets), finished product specifications, production capacity targets, workshop layout, and the needs of the next process. Including for special materials such as coated cardboard, changing the feeding mechanism to ensure that production can continue and adapt.

7. Automatic classification and sorting system

This is a big step toward intelligent equipment. It can automatically sort the die-cut cards according to the preset logic through the high-sensitivity photoelectric sensor or image recognition system.

- Sequential collection: The original order of the cards as they are punched out is maintained exactly. This is very important for making items such as playing cards that need to be in a certain order.

- Collect by category: The machine can automatically put the cards into different collection slots according to the pattern, color mark, or built-in chip information printed on the surface of the card. For example, cards of different rarities in the same set can be automatically packaged separately. This saves a lot of manual sorting time and money, making the process more efficient and accurate.

8. 7.5 kW servo drive system with burst power

The main transmission adopts a high-power (7.5 kW) AC servo motor, replacing the ordinary motor or mechanical transmission. It has the following advantages:

- Fast response: can be started and stopped immediately, shortening the cycle and speeding up production (the maximum stamping frequency can reach 100-150 times per minute, depending on the card size and material).

High-precision reducers can digitally and precisely control the position and pressure of stamping, and the repeated positioning accuracy is very high.

- Energy saving and environmental protection: It only consumes electricity when it is working, and the power consumption is extremely low when it is not working. It saves 20% to 30% of electricity compared with traditional equipment.

- Smooth operation: It reduces noise and vibration, improves the work area, and helps extend the life of the mold.

9. Customized finished product collection method

You can set up the finished goods collection unit in the way that best suits your customers:

- Card stacker: Stacks cards neatly to a set height for bulk movement

- Counting and packaging collection: connect to the automatic packaging machine; when a certain number (such as 50 or 100 sheets) is reached, the counted paper is automatically pushed into the packaging film.

- Conveyor belt outflow: directly to the downstream station for plastic sealing, packaging, or quality inspection; can be used for assembly line operation.

10. Intelligent control supported by parameter data

The human-machine interface (HMI) touch screen allows you to set and save all production parameters, such as pressure, speed, step length, and sorting logic. You can store hundreds of different product production schemes and call them with one click when changing orders. This saves a lot of time and material waste when adjusting the machine. The system can also track information such as the number of items produced, the running time, and any faults that occur. This data can be used to help with production management and efficiency analysis.

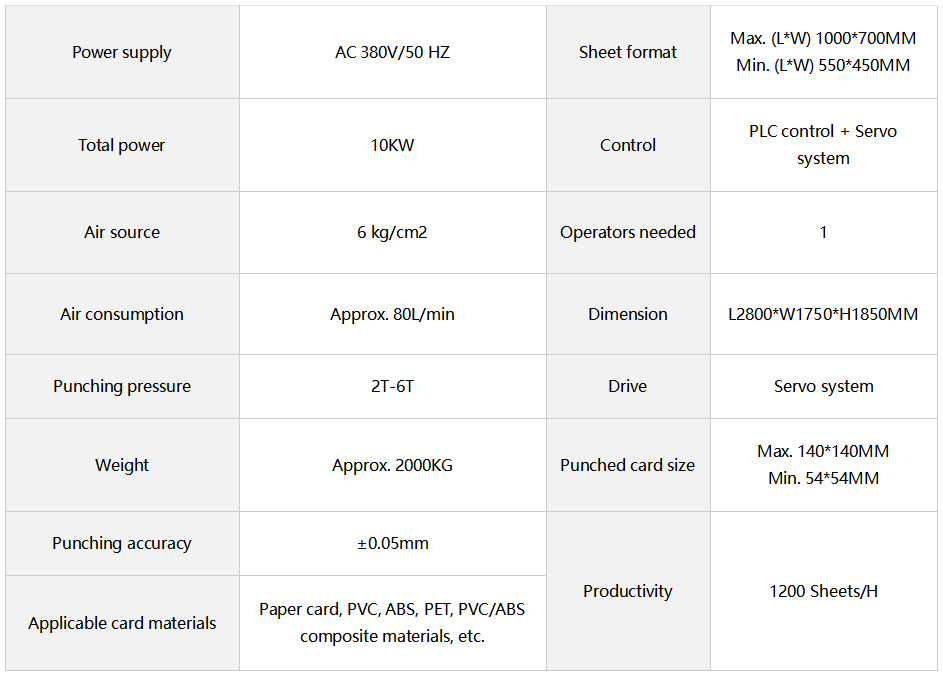

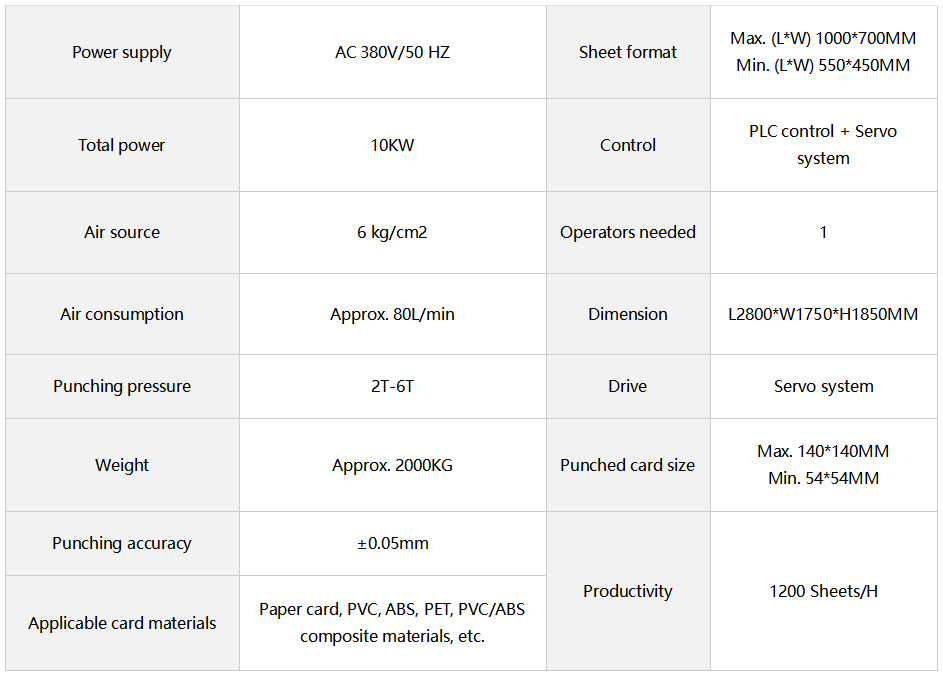

3. Main technical parameters of the star card die-cutting machine

The following parameters are common settings that can be changed to suit your needs:

Summary

The Starcard die-cutting machine is the reliable, efficient, and intelligent productivity core for global card manufacturers, security printing companies, and high-end printing and packaging service providers. It has the characteristics of accurate punching and cutting without burrs, a high degree of automation integration, flexible multi-purpose use, and a strong 7.5 kW servo drive. Its automatic sorting and classification function directly hits the pain points of the industry and transforms the labor cost of the back end into the benefits of automation. Our R&D and manufacturing center in Shenzhen, China, has been focusing on how to use the latest technology in the engineering field to ensure that all our factory equipment is of high quality and works reliably for the global market. It is your best partner to build more competitive card products and move toward intelligent production.