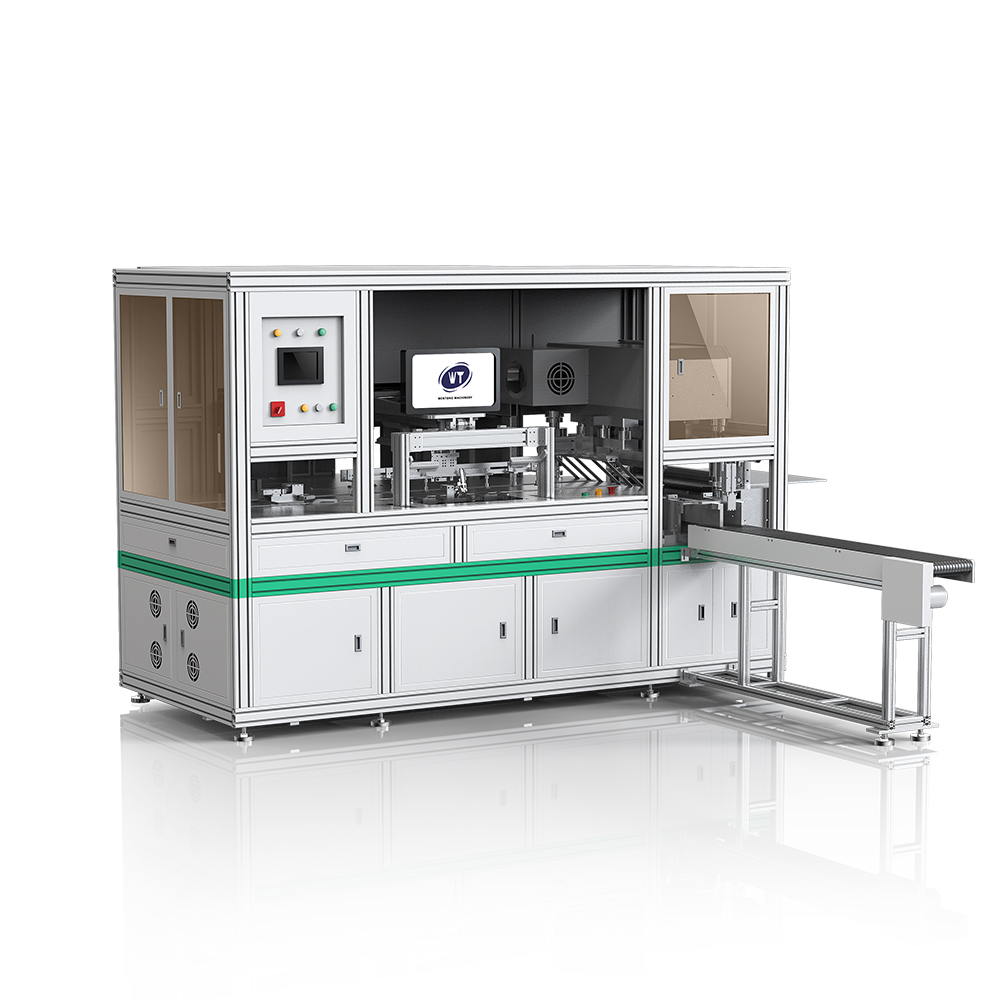

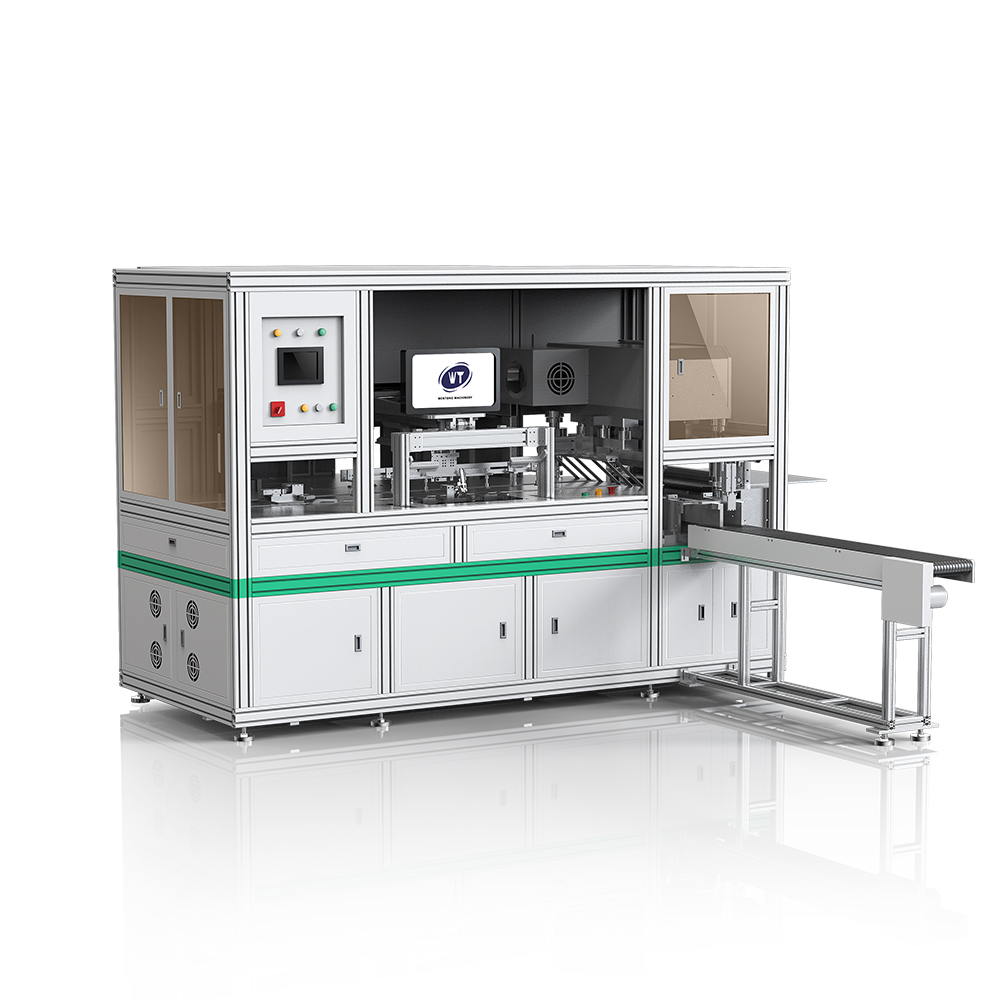

The bank card punching machine is a high-end die-cutting tool that can quickly and accurately produce a large number of different cards. Its main job is to accurately cut and punch various cards. It also has an intelligent automatic classification and sorting system, which can realize the assembly line operation from raw materials to finished cards. This machine is not only a punching machine but also a complete card-making terminal solution.

When it comes to its main function, the bank card punch machine does a good job in many aspects:

Unique feel and precise punching: The machine has a very rigid body structure and a very precise guiding system. The punching process is stable and vibration-free. The punching section is flat, without burrs or delamination, because the precision mold adopts unique alloy steel. The edges of the punched cards, whether PVC, PETG, ABS, or a combination of these materials, are smooth and neat. Meet the strict edge quality standards of bank cards, smart cards, and other cards. The actual punching accuracy can reach ±0.05 mm, which ensures the consistency of all card sizes.

Excellent durability and stability: The main parts of the machine are made of high-strength cast iron or steel plate welding. After stress relief treatment, it will not deform after long-term use. The crankshaft, connecting rod, and guide rail are important moving parts. They are made of wear-resistant alloy and heated in a special way. Even when the equipment is running at full capacity 24 hours a day, the central automatic lubrication system keeps it running smoothly with minimal problems. The mean time between failures (MTBF) is far longer than the industry standard, which keeps customers’ production lines running.

Wide range of applications and multiple functions in one machine: Although it is called a bank card punching machine, it can do much more than that. The equipment’s mold can be quickly replaced to produce standard-sized cards such as smart cards (SIM cards, access cards), game cards, collectible animation cards, high-end playing cards, membership cards, and ID cards. Due to the high pressure and high control precision, it can also punch and cut special thick paper products such as hardcover book covers, industrial filter paper, and high-grade leather accessories. This means you can do a lot with one machine, maximizing your investment.

The integrated hot stamping surface treatment process can add an online hot stamping unit to the equipment. Die-cutting and hot stamping (hot stamping color blocks, text, and patterns) can be completed at one time. This method reduces the number of times the card moves between devices, avoids registration errors and surface scratches, and greatly improves production efficiency and yield. It is especially suitable for high-end products such as bank cards and gold and silver commemorative cards.

Mature overall customized solutions: Our Shenzhen R&D and manufacturing team has more than ten years of experience in precision machinery manufacturing. We not only sell a device but also provide a full set of customized services, including material testing, mold design and production, equipment debugging, equipment maintenance, and so on. We can help you build the most suitable production line for your card material, size, output, and factory layout.

Automated sorting and collating: The best thing about this machine is that it can automatically sort and collate cards. The cards are not just randomly stacked after being punched. Instead, they are automatically sorted by the built-in high-speed visual recognition system or the preset logic. For example, they can be classified by chip type, batch, good product, or defective product. The conveyor system delivers the sorted cards to different collection units, and the whole process does not require manual intervention.

The core of high-efficiency automation drive: The main part of the high-efficiency automation driver is the high-performance servo motor drive system, which has a large power (such as 7.5 KW). Compared with ordinary electric or pneumatic motors, servo systems have stronger control over speed, position, and torque. The stamping action is also faster, more stable, and consumes less power. The touch screen HMI can set and save the stamping parameters of hundreds of products, such as pressure, stroke, speed, etc. When changing products, you only need to call it with one click. This makes debugging much faster.

Flexible, customized finished product collection: There are two main automated collection systems that can be used for different types of production:

1. Collect in order: Make sure that each stack of cards is in the same order, and stack them in the order in which they were punched and cut. This makes it easier to keep track of the order for personalization coding, packaging, or distribution.

② Collect by category: Different types of cards enter different collection boxes or assembly lines connected to the sorting system. In this way, mixed production of different types can be output and sorted at the same time.

2. Customized solutions for card punching machines

The traditional card-making method in the card-making industry often encounters many problems. The bank card punching machine is manufactured to solve these main problems:

Solve the problem of accuracy consistency: manual or semi-automatic punching, large size error, and many burrs, affecting the readability and quality of the card. The fully automatic precision control is adopted to ensure the consistency of the geometric dimensions and edge quality of each card. The scrap rate is also very low.

To solve the efficiency problem: In the past, people mostly punched, sorted, and counted separately. This is both time-consuming and labor-intensive, and it is easy to make mistakes. Integrated automatic design combines multiple steps into one. Hundreds of holes can be punched per minute, while sorting and collecting are carried out simultaneously, greatly accelerating the speed.

Solve the problems of high labor costs and easy errors: manual sorting of cards is labor-intensive, and when a large number of similar cards need to be sorted, the eyes are easily fatigued, and there may be omissions or errors. Automated vision sorting systems can work 24/7 and have an accuracy rate of nearly 100%. This means it is less reliant on skilled workers and human error.

Production and production line changes are more flexible: small batch, multi-variety orders increase, and mold and production changes are too frequent, resulting in excessive downtime. The equipment’s quick mold change system (QMC) and servo parameter storage function can shorten the changeover time to the minute level, making flexible production possible.

To solve the problem of long production processes: secondary processing such as hot stamping requires separate equipment and processes. This makes the processing and waiting time longer. With the hot stamping all-in-one machine, it can be completed online at one time. In this way, things become simple, the inventory of semi-finished products is reduced, and the entire delivery cycle is accelerated.

Addressing data traceability and management issues: The automated system is connected to the MES (Manufacturing Execution System) to track information such as manufacturing volume, sorting type, and current status of the equipment. This helps manage production and digitally track quality.

3. Main features and technical details of the equipment

The reason why the bank card punch is easy to use is that the technical specifications are strong and the settings are good. Here are the most important technical details and common settings for this series of machines (models may change):

Mechanical structure: Four-column or gantry-type body, high rigidity, cast-welded built-in, even if the long-term heavy load can maintain the accuracy unchanged. Heavy-duty bearings and precision roller guide rails, smooth movement, not easy to wear, long service life.

Drive system: High-performance servo driver and reducer, full servo motor drive (such as 7.5 KW). It allows you to precisely control the stroke and move smoothly at different speeds. It also saves about 30% of the energy compared to the old machine.

Punching system:

You can change the maximum stamping pressure as needed (for example, between 50 and 300 tons).

The punching accuracy is ±0.05 mm.

Max. Die-cutting Area: The standard size is 780 mm x 1050 mm, but you can change it.

Maximum stroke (can be changed): but usually between 100 and 150 mm.

The speed of punching depends on the type of card and the number of layouts. 200 to 600 punches could be made per hour.

Control system: The system is controlled by a programmable logic controller (PLC) and a multi-point touch color human-machine interface (HMI). The interface is simple and easy to use, supports multiple languages, can save a large number of mold settings, and can find problems by itself.

Feeding and positioning system: Adopt a servo-driven front and rear positioning mechanism or an automatic feeder feeding system. The grating ruler or visual positioning can make the feeding accuracy reach within ±0.1 mm.

Automated sorting system:

There are two ways of sorting: one is to use the visual recognition system of an industrial camera (CCD), and the other is to use the logic sorting of sensor signals.

Identification content: patterns, colors, hole positions, chip positions, QR codes, barcodes, and other things that help identify.

Sorting lanes: You can add more sorting lanes if needed, but there are usually 2 to 6.

How to collect finished products:

Sequential picking: A robot or conveyor belt stacks the items, automatically counting them and sensing their height.

Sortation collection: Collection bins or multi-exit conveyors connected to sortation lanes.

Safety system: in accordance with CE and other international safety standards, with grating safety protection, a two-hand linkage button, an emergency stop device, an abnormal air pressure alarm, etc.

You can also get an in-line hot foil stamping unit, a waste stripping system (waste stripping machine), a vacuum device, a remote monitoring interface, etc.

4. Application scenarios and target customer groups

Our bank card punching machine is mainly for high-end card manufacturers abroad and enterprises that need very precise die cutting. We make precision equipment in Shenzhen and sell it all over the world. Here are some common uses and customer groups:

Bank card and security card manufacturers produce a variety of types of cards. These include credit cards, debit cards, prepaid cards, access cards, and employee badges. These tools need to be very precise, have high security standards (no burrs on the sides that could prevent information from being recorded), and be able to sort themselves (by different bank BIN numbers or chip types).

Smart card and electronic tag manufacturers: SIM cards, transportation cards, social security cards, and RFID/NFC tag punching and sorting require smart card and electronic tag manufacturers. The equipment must not apply any pressure to the built-in chip and must be able to correctly classify chip cards of different frequencies or models.

Game and anime products company: This company produces trading card games (TCG/CCG), board games, and anime card collectibles. The equipment can easily handle small batches and orders with a large number of different patterns. Automatic sorting also allows cards to be sorted by series and rarity, making subsequent packaging work easier.

Poker and Specialty Printing: They use them to make high-end playing cards, hotel room keys, and promotional gift cards. It should have smooth edges and feel good. The hot stamping process can make the product better.

Industrial and special material processing: used for punching and cutting materials such as medical test strips, flexible circuit board (FPC) auxiliary materials, insulation materials, and composite material sheets, with high precision. Taking advantage of its high punching precision and wide application range.

Bookbinding and box-making companies: they come to cut and shape the covers of hardback books and the linings of fancy gift boxes. They also use them to handle thicker cardboard or other materials made of multiple materials.

In short, the bank card punching machine is the most advanced high-end equipment manufactured in Shenzhen. It combines precision mechanical engineering, automatic control, and visual recognition technology to provide efficient, high-precision, and high-flexibility production solutions for the global card-making and related industries. It not only helps customers cope with the ever-changing needs of the market but also is the key equipment for customers to realize intelligent upgrading and enhance their core competitiveness.