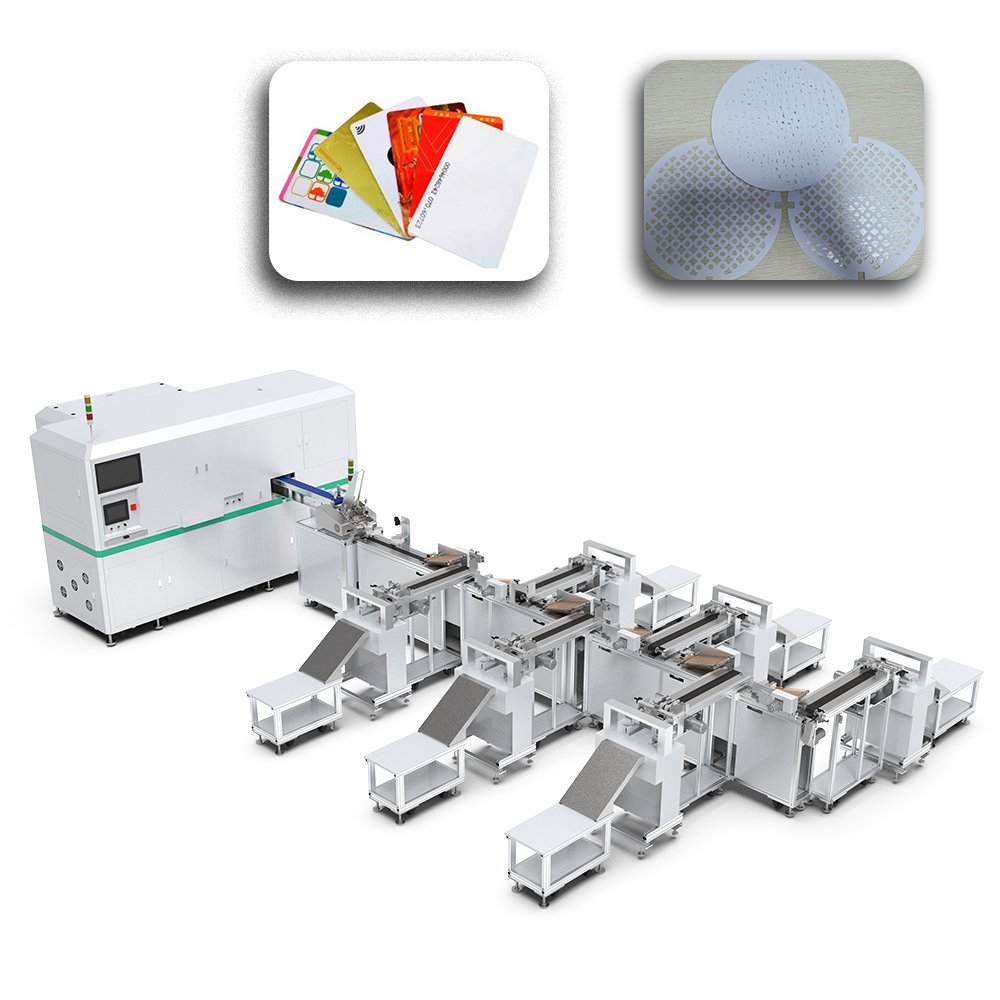

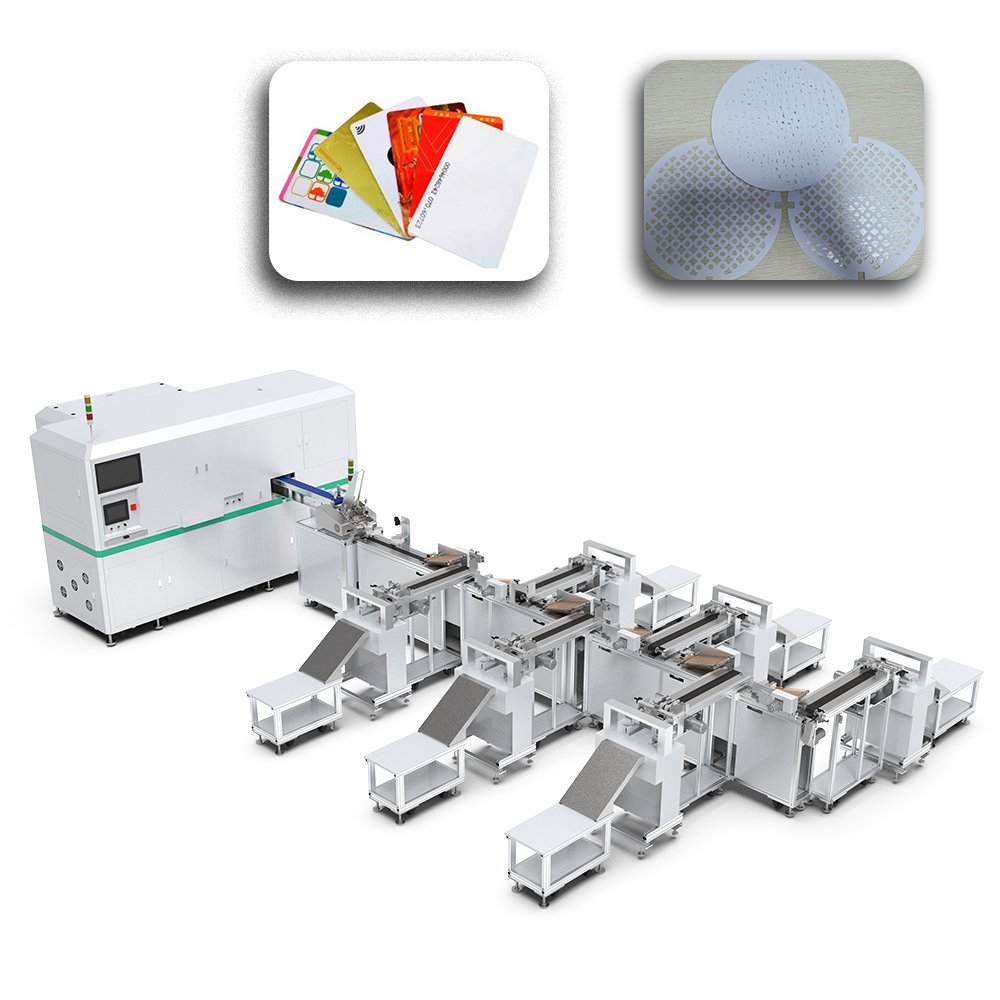

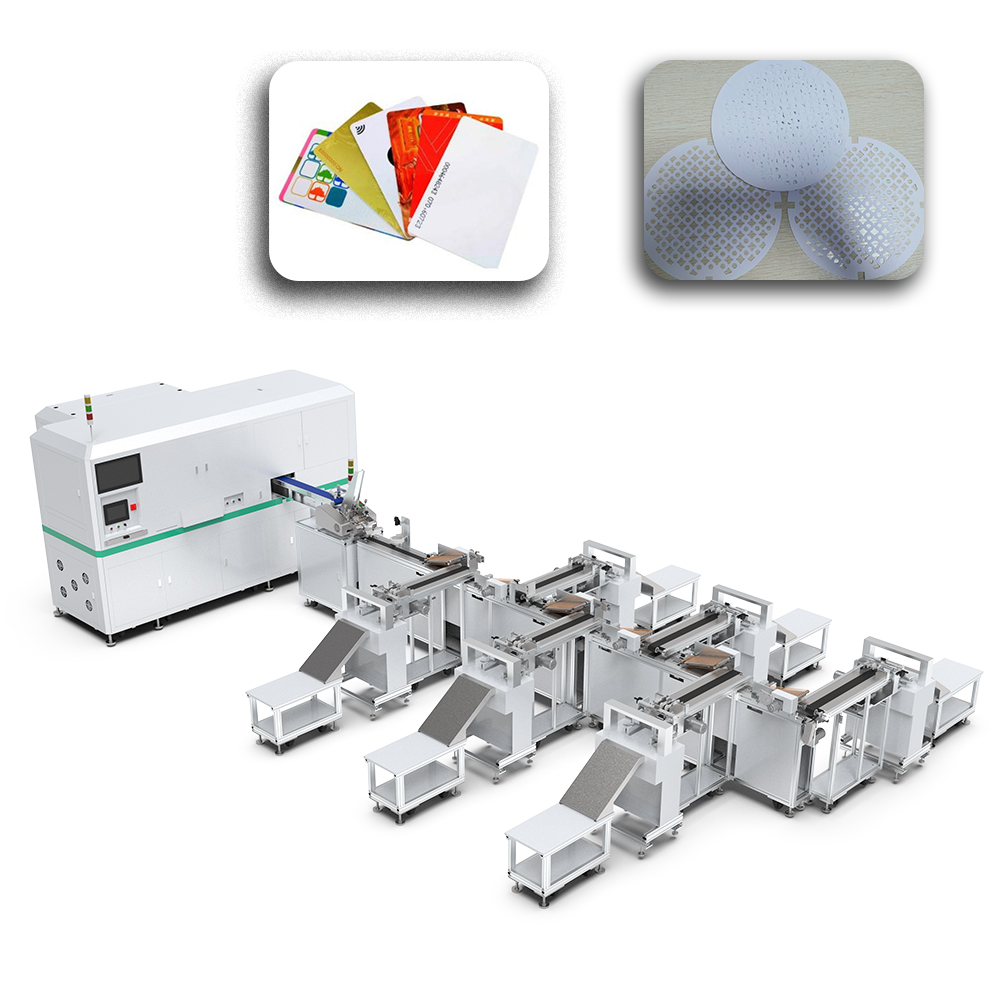

Application field of the Wentong card punching machine

Every manufacturer in the industry, whether a playing card manufacturer, a smart card manufacturer, or a special filter paper processing plant, faces the problem of how to process various materials and product specifications in a timely, accurate, and economical manner while adding value to the finished product. The market demands efficiency, precision, and flexibility. As a result, the old-fashioned manual methods or single-function systems are no longer feasible.

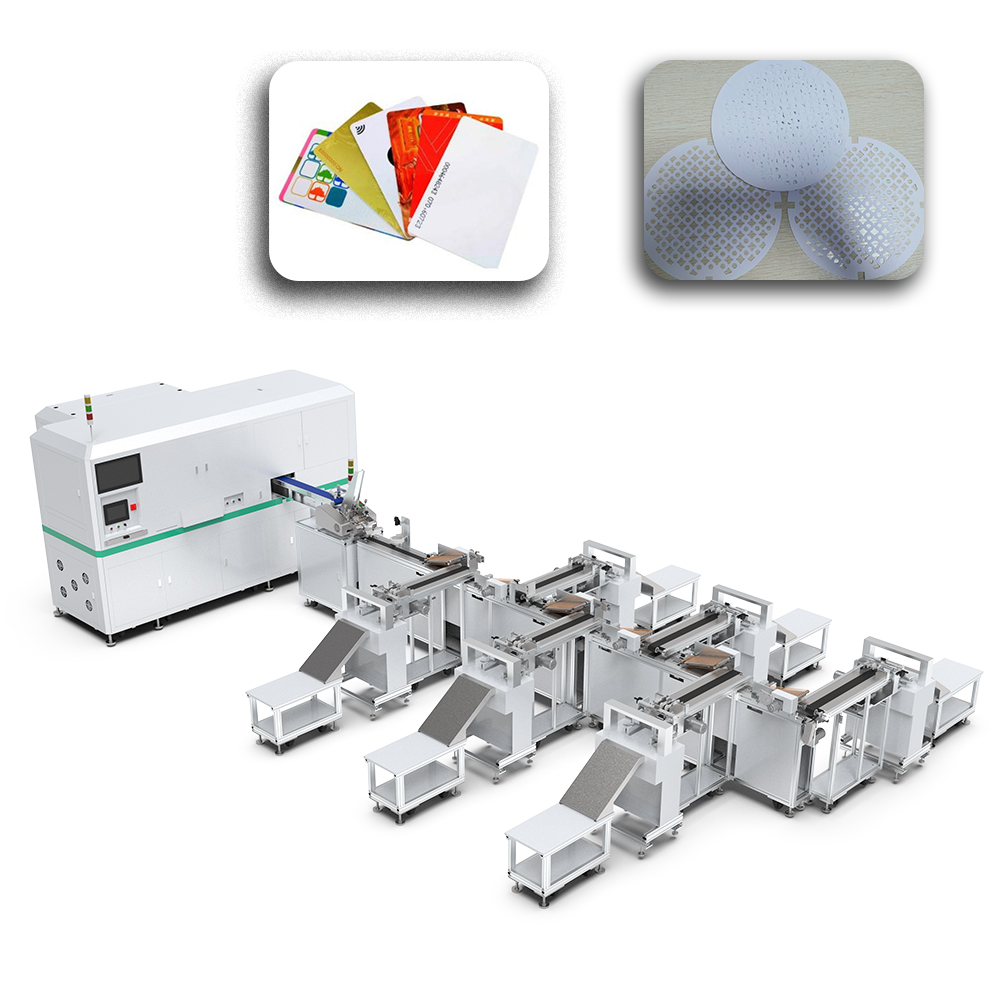

Wentong years of technical expertise and a deep understanding of the global market, Shenzhen Wentong Machinery proudly presents this most advanced high-performance

card punching machine. It is not only a punching tool but also integrates a fully automatic customized card sorting and sorting system, which is designed to be the main power of your production line.

1. Application range of card punching machine

The punch press is designed to handle any type of material, so users in any industry can take advantage of all its features.

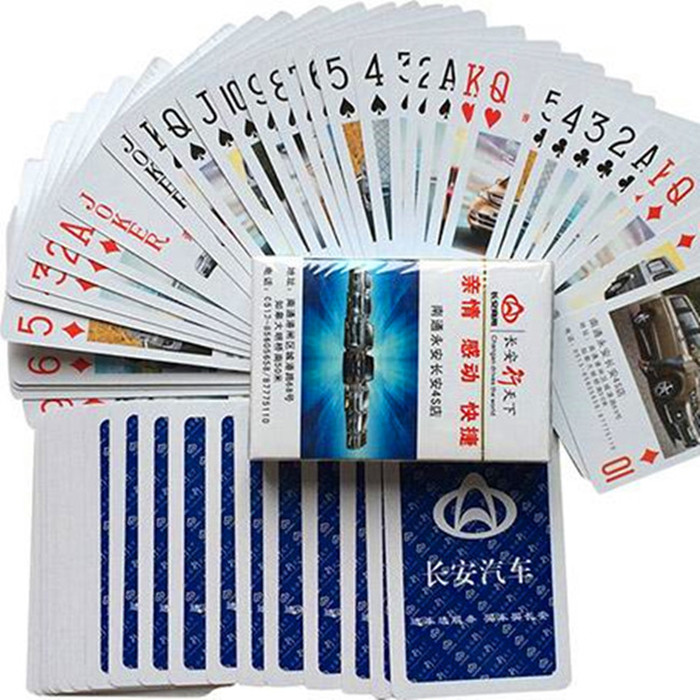

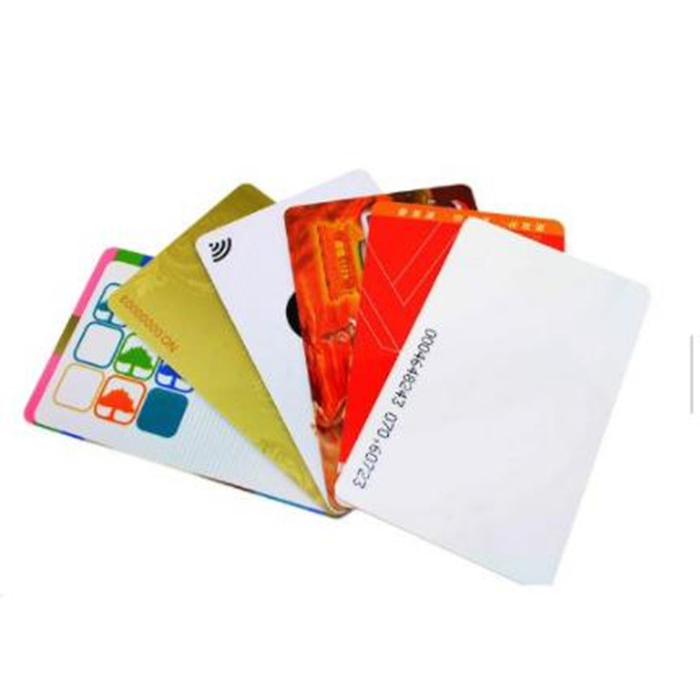

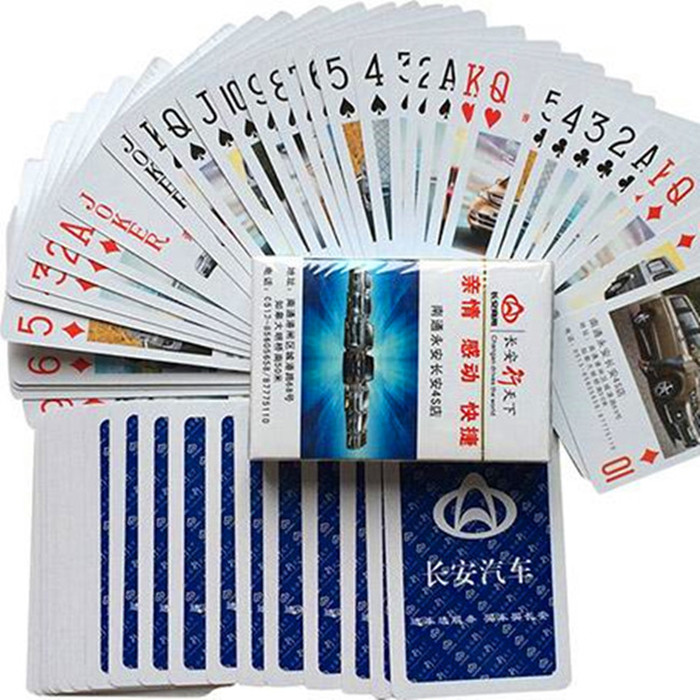

Card production:

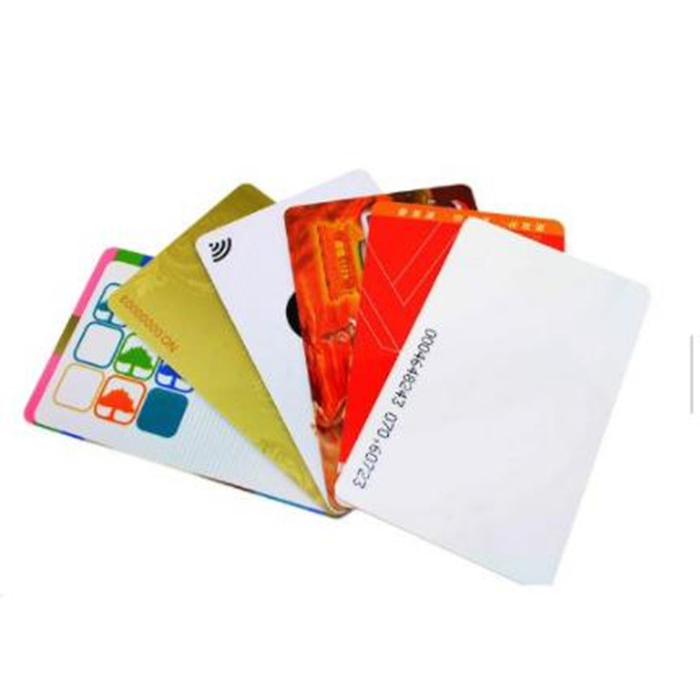

The products covered are game cards (such as collection cards), membership cards, smart cards, ID cards, gift cards, etc.

Material adaptation: cardboard, fiber, wood polymer, PVC, and other materials can be integrated and processed at the same time. The punching machine can produce the articles of various thicknesses and densities and can guarantee that the edge is free of burrs so as to make the product have a high-grade sense.

Filter paper and special paper punching:

The products covered are oil filter paper, air filter paper, steaming paper, polishing paper, filter paper, and other special types of industrial paper.

Material adaptation: various papers, fiber composites, and layered materials. The punching precision meets the diverse needs of various industries for the filtering capacity of paper.

Other paper and plastic products:

Literacy books, booklets, packaging boxes, puzzle cards, and steamed bun mats are punched and bound in large quantities.

Target customer group:

Card manufacturers, the printing and packaging industry, filter manufacturers, stationery manufacturers, filter hardware manufacturers, plastic processing plants

2. Ten features of the card punching machine

Our

card punching machine has been upgraded in technology and practicality:

1. The punching machine is accurate and burr-free.

The die-cutting machine design includes highly precise control technology and comprehensive die design, enabling the machine to operate with surgical precision. The equipment provides consistency, making the edges of all products perfectly even and smooth. The details of the surface treatment greatly enhance the value and visual appeal of the product.

2. Durability of the punching machine

The core components of the

card punching machine are optimized by finite element analysis and manufactured with high-strength alloy steel, and the high wear-resistant parts are integrated to ensure the stability of the machine under long-term high-load operation. This reduces operating costs, extends service life, and will bring a high return on investment for the machine.

3. The punching and cutting machine is multi-purpose.

This excellent machine has two main functions. The card production line and filter paper processing line can be switched flexibly by simply changing the mold and adjusting the machine parameters. This operational flexibility has greatly expanded the business potential.

4. Die-cutting machine with hot stamping function

For hot stamping applications, high value-added products can integrate hot stamping functions when setting up finishing equipment. Card handling can be integrated during hot stamping (e.g., for some membership cards or game flash cards), without the need for additional equipment and processes.

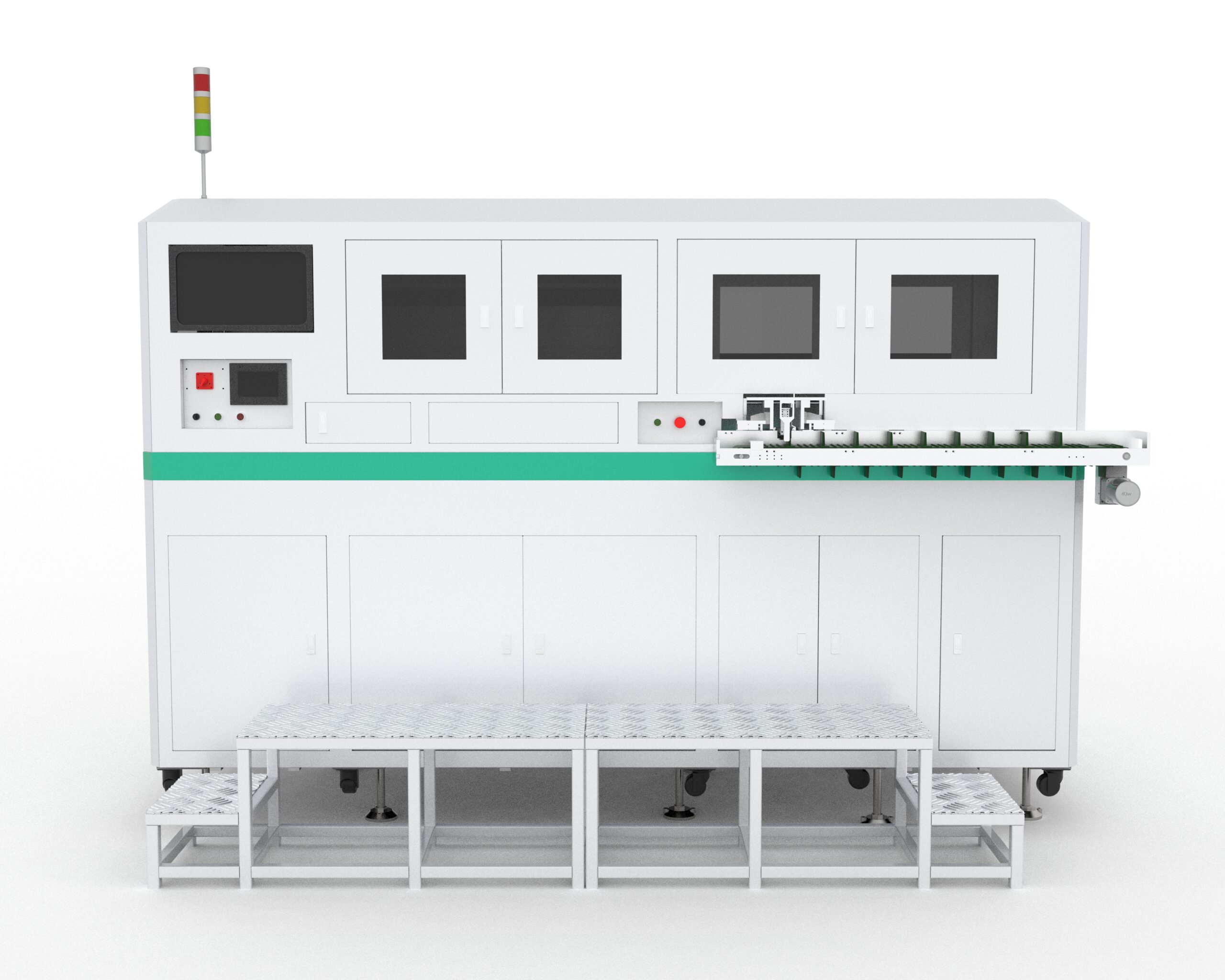

5. The powerful power core of the punch card machine

The punching machine is equipped with a 7.5 kW high-power servo motor to provide controllable, stable, and strong punching power. Different from hydraulic or mechanical power, the servo motor control system has the characteristics of low noise and fast response time, which can realize efficient and energy-saving production.

6. Automatic classification and sorting function of punching machine

The sensing and control system of the die-cutting machine sorts and classifies the final products according to the preset parameters. The patterned playing cards, paper, and filter paper grades can then be separated into unique collection areas.

7. Customized finished product collection method

We offer tailor-made collection solutions for your needs in packaging or further processing after automated sorting:

① Collect in order: Stack strictly according to the punching and cutting order to maintain the continuity of the product and the integrity of the batch. It is especially suitable for products with strict sorting requirements.

(2) Collect by category: According to the sorting results, products of different categories are arranged or collected into different containers, which is convenient for direct sorting and packaging, thus improving efficiency.

8. Integrated customized overall solution

We understand that each customer has different specific production needs. Therefore, in addition to our standard models, we aim to provide you with comprehensive customized solutions. Including material testing, mold design and manufacturing, equipment integration supporting functional modules (such as hot stamping and sorting), finished product collection solutions, etc., to develop a comprehensive and coordinated technical support system to ensure that our system is seamlessly connected with your production line.

3. Why choose us?

Geographical and industrial chain advantages: Shenzhen, China, is known as the “Silicon Valley of the world’s hardware.” With the regional supply chain and engineering talent, we are in a favorable position for device R&D.

Global Focus: Our equipment is manufactured with the global overseas market in mind and therefore meets international safety and electrical standards. With our extensive export experience, we can provide after-sales service and technical support to customers worldwide.

Professional and authoritative: We have great advantages in stamping and cutting. Our engineers have rich industry experience and can provide you with the most professional consultation and guidance to help you solve the most challenging production problems.

Concluding remarks

In the current industrial pursuit of ultimate efficiency and excellent quality, the correct choice of equipment is becoming more and more important. Thanks to their outstanding durability, wide range of multipurpose applications, automated intelligent classification and sorting capabilities, and highly customized overall solutions, our

card punching machines are becoming the secret weapon of many well-known enterprises around the world.

The punching machine will provide you with the quality and efficiency of card production you want, and it will become a reliable partner for you to explore new business areas (such as filter paper punching).