1. The main features and functions of the game card punching machine

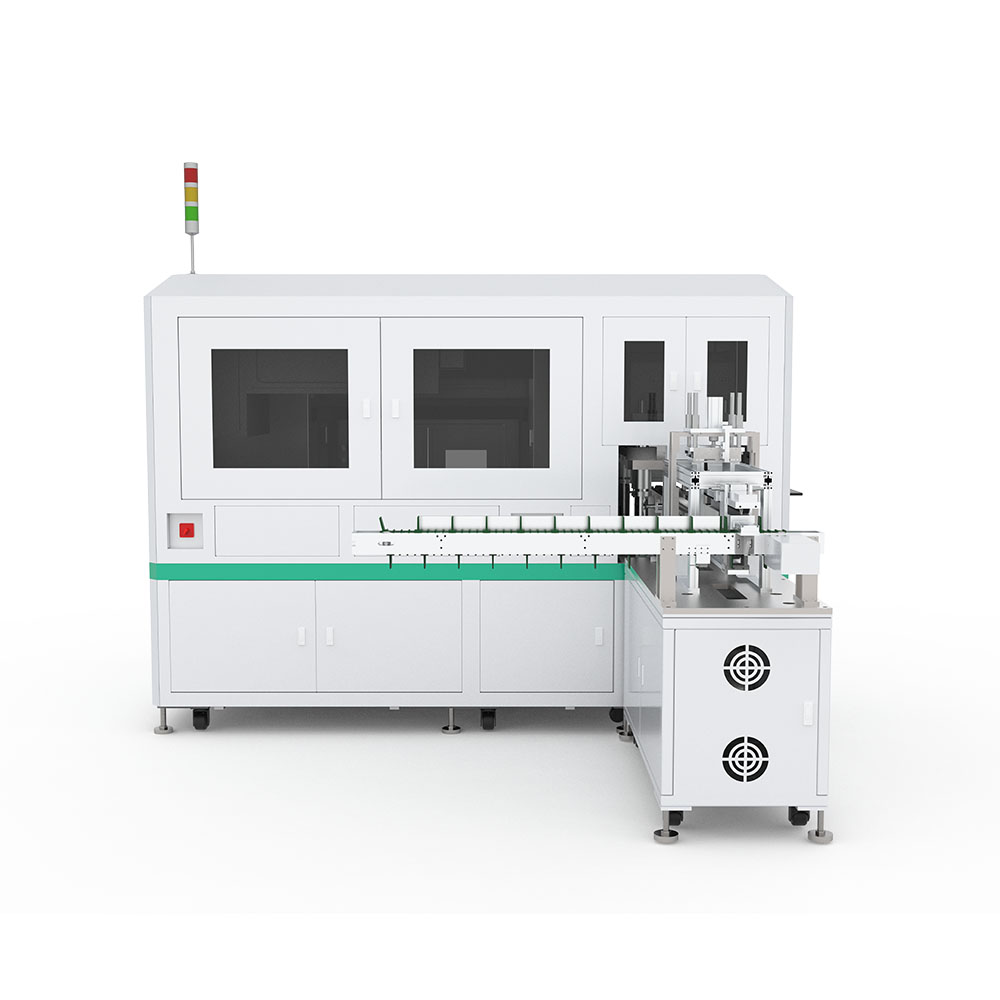

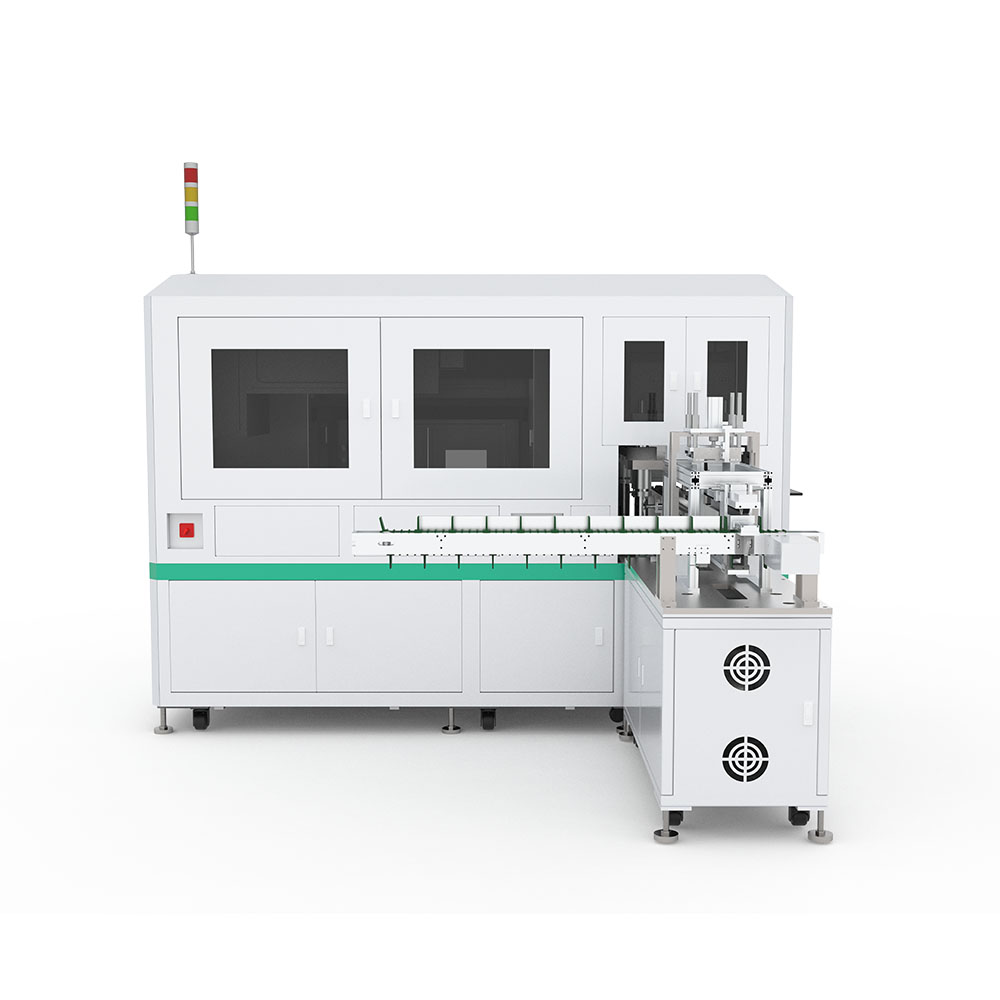

In the card manufacturing business, which includes game cards, smart cards, bank cards, membership cards, promotional cards, and even high-end collectible cards, the most important factors that make a company competitive are the speed, accuracy, and consistency with which they produce finished products. Many times, traditional game card punching machines have problems doing multiple things, staying automated, and staying stable for long periods of time. To solve these major problems, Wintone’s manufacturing centre in Shenzhen, China, has been producing precision machinery for many years and has created and released a new series of high-performance game card punching machines. The machine can not only punch cards but also automatically separate and collect cards. It is manufactured to meet the strict

Excellent punching accuracy and burr-free quality: The main advantage of the machines is that they can punch very precisely and leave no rough edges. The high rigidity of the

Automatic sorting: One of the best things about this game card puncher is that it can sort and organise the cards on its own. The machine can sort the punched cards according to the set programme:

Sequential collection means that the cards must always be kept in the same order after they are punched. This is very important for making game cards and animation card albums, because these card albums need to be coded, paired or packaged into sets later.

Group by category: Cards can be automatically sorted and grouped according to colour, pattern, chip type (for smart cards) or any other preset function. This can be done by visual recognition or mechanical sensing systems. You can then move the card to

Strong multi-application and scalability

The cover and hangtag of this book are die-cut.

Manufacture and die-cut industrial filter paper and gaskets to size.

You can use the optional hot foil stamping unit to perform local hot foil stamping at the die-cutting station simultaneously or at different times. Die-cutting and decoration are combined to speed up the production process. Customers can grow their business with good hardware support, and the equipment can be easily changed to meet market demand.

Long-lasting durability and unique texture

Card manufacturers around the world are facing the same problems: rising labour costs, zero tolerance for product defects, a trend of small-batch and multi-variety orders, and the need for traceability of production data. To solve these problems, we have created the game card punching machine:

Solve the problem of manual dependence and error: people do not have to do the same boring work over and over again because the process of punching, sorting and collecting is automatic. One person can monitor the work of many devices at the same time. This will avoid the problems that may occur during manual sorting.

Solve the bottleneck of production efficiency: 7.5 kW high-power servo drive system, giving you strong and stable power, high punching frequency, and fast response speed. At the same time, it is equipped with an automatic feeding and receiving system, which can realise rapid continuous production and greatly improve the production capacity per unit time.

Solve the problem of insufficient flexibility: from thin smart cards to thick game cards, as well as composite bank cards, paper animation cards, etc., can be applied. This solves the problem of insufficient flexibility. You don’t have to buy a lot of equipment, which saves money and allows you to respond to market changes more quickly.

Solve the problem of quality consistency: the full closed-loop control system detects the stamping position and pressure in real time to ensure that each product of each mould is the same. No matter how many you order, whether it’s 100,000 or 1 million, the first and last sheets will be of the same quality.

Provide customised overall solutions: We know that each customer

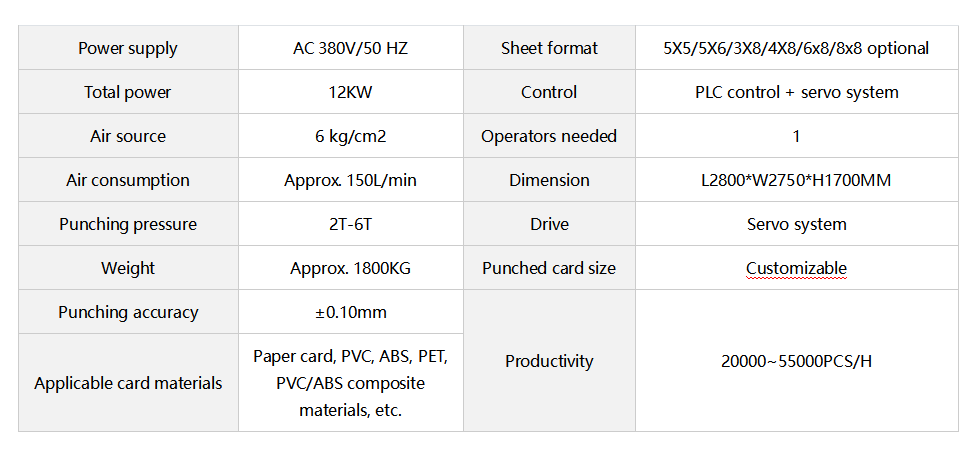

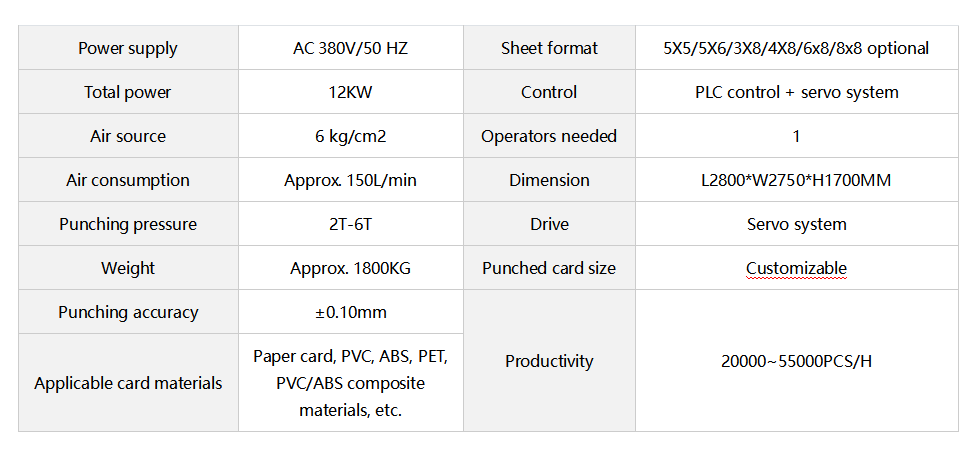

3. Technical information and equipment parameters of the game card charging machine

The device works well because it has a high-quality manufacturing process and a well-planned advanced technology setup.

Drive system: linear guide rail, precision ball screw, 7.5 kW high-power AC servo motor drive. High motion control accuracy, high reset accuracy (±0.01 mm). It runs quietly and does not consume too much energy. Its service life is much longer than that of ordinary hydraulic or mechanical drives.

Control system: It adopts a factory-used PLC and a colour human-machine touchscreen interface. This makes it easy to use. You can save hundreds of sets of production parameters of different products, such as pressure, stroke, speed, sorting logic, etc. They are easy to get. It can

Automatic sorting system: The automatic sorting system is a highly reliable mechanical sorting system that uses sensors as the standard. It can also have a machine vision recognition system to perform more advanced image recognition and classification. The sorting accuracy rate is above 99.9%.

Punching unit: The punching unit adopts a solid two-column or four-column guide structure so that the force is uniform. The punching pressure is usually between 20 tonnes and 80 tonnes, but you can change it as needed. The grinding accuracy of the workbench is very high, so the mould can be installed perfectly.

Customised collection methods: Provide

Technical parameter example:

4. Application scenarios of game card recharge machine

Due to its accuracy, automation and adaptability, this playing card punching machine is the best choice or upgrade for production companies in the following fields:

Gaming and Entertainment Industry: For the production of trading cards (TCG), board game cards, chess and playing cards, scratch-off lottery tickets, collectible cards, and more for the gaming and entertainment industry. The automatic sorting function is ideal for

Financial and security certificate industry: used for punching and cutting chip modules, forming smart cards such as bank cards, credit cards, membership cards, access cards, ID cards, and ordinary magnetic stripe cards.

Anime and cultural creative products: making high-quality cards such as anime character cards, star collection cards, and promotional cards. The choice of hot stamping process makes the product more beautiful and valuable.

The application now includes die-cut book covers, high-end gift box liners, precision paper or non-metallic industrial gaskets, filter paper, etc. These are examples of packaging and industrial parts. This shows that it works well in other countries.

This game card punching machine can punch with high precision, automatically classify, and do many other things. This shows that the card-making industry is transforming to intelligence and flexibility. It is not only a tool but also a wise investment, which will help customers’ products become more competitive, make the production process more perfect, and reduce the overall cost. Our Shenzhen team will continue to provide all-round service support, from helping global customers get their first opportunity in the card-making field to selecting the right equipment and combining them together.