In the printing, packaging, and advertising products industries, the dominant factors that determine the competitive advantage of enterprises are production efficiency and product quality. In the post-processing of materials such as posters, learning cards, and EVA foam, the traditional manual winding and stacking operations have become the key bottlenecks that restrict production capacity, increase costs, and lead to product inconsistency. Against the backdrop of the global market’s urgent need for efficient, accurate, and automated production systems, we are based in Shenzhen, China, and after years of continuous technical investment, we have recently launched a new generation of high-performance paper winding machines. The paper winding machine is designed to solve the most important problem of manual paper winding and provide customers with a fully integrated intelligent paper winding solution.

1. Pain points of the paper rolling machine industry

For partners who previously relied on manual paper roll operations, what problems did this direct reliance on manual paper roll operations cause?

Low efficiency and limited capacity:

Manual winding is slow, which becomes the bottleneck of the production line and affects the order delivery cycle.

High labor costs and management difficulties:

The company relies on skilled personnel, but the high mobility of skilled personnel increases the cost of uneven training and management and also increases the difficulty of controlling operational consistency.

Inconsistent, affecting the appearance of the product:

Manual operation is like an unsynchronized machine, producing insufficient consistency, and metering is provided by uncontrolled controls. Each roll is produced under unnecessary and unexpected pressure, with slippage as standard, creating dents or distortions in the gaps, and accompanied by loose material slack. Any extreme of these loose ends will detract from the professional appeal of the product and create a risk that the company may wish to hide from its customers.

Material waste is severe:

attempts to optimize winding through operation always cause the material to collapse with unnecessary pressure and winding imbalance, which provides a dilemma for profits.

Difficult to cope with diversified demands:

When customers need single-sheet winding or multi-sheet combined winding, it is almost impossible to realize standardized batch production through manual operation.

Our rewinders have taken into account all the possible problems that may occur and are the inevitable solution in the production process when it comes to cost reduction, efficiency, and quality improvement.

2. Core advantages of the paper rolling machine

Focusing on the pain points of the industry, our mechanical engineering and intelligent control technology have achieved the five key attributes of the paper roll machine:

Feature 1: High-efficiency automation, freeing up manpower and increasing production capacity

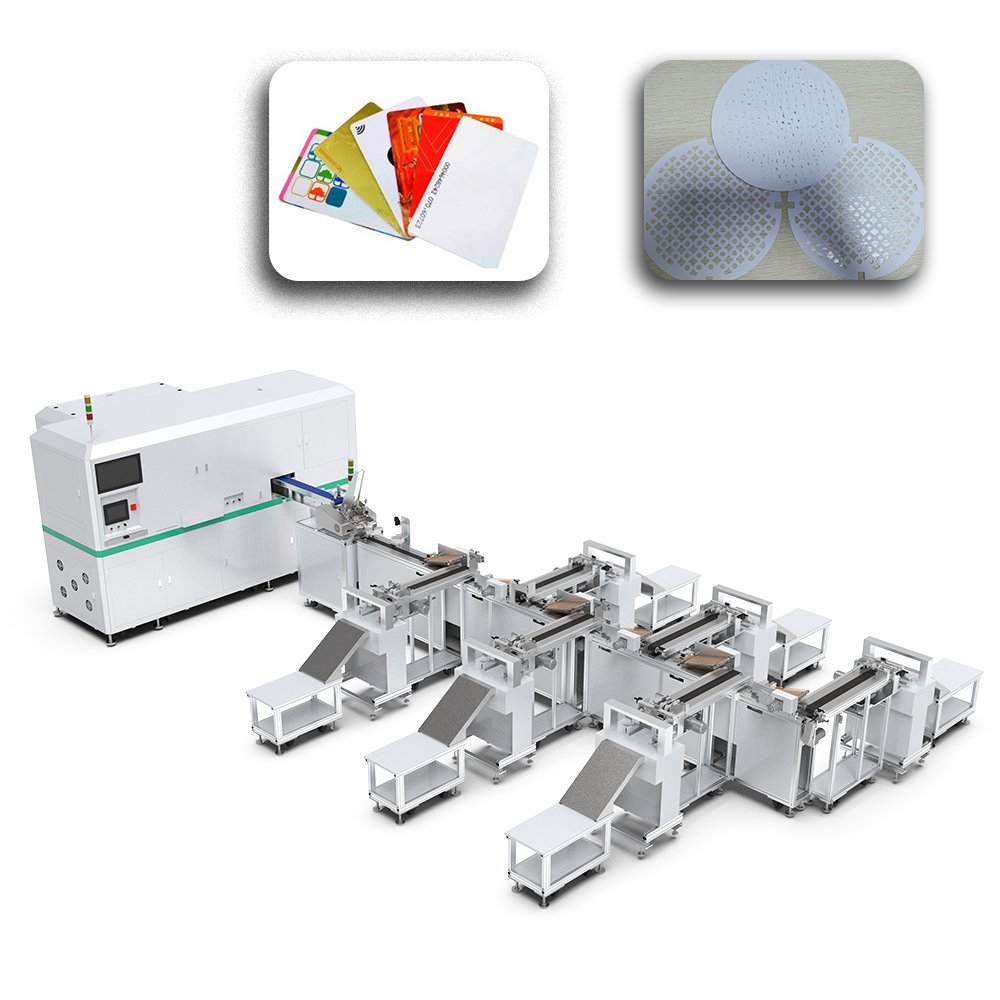

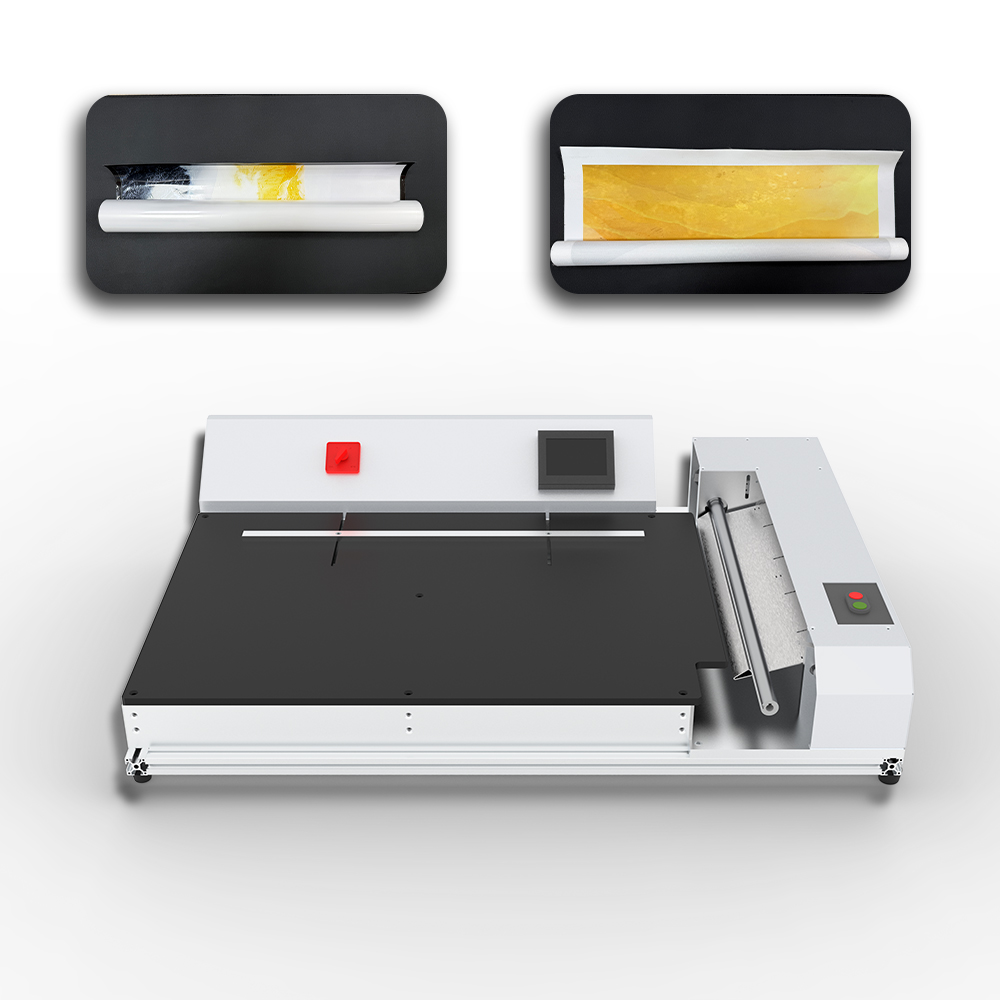

Both the automatic and semi-automatic paper roll configurations are equipped with automatic feeding, winding, sorting, and unloading. The entire system runs continuously at high speed during the paper rolling process, with a small load and few controls.

Value: One machine can replace several skilled workers, realize 24-hour uninterrupted operation, and improve the 24-hour production balance. The production efficiency of each machine is at least 300% higher than that of manual operation, ensuring the continuous production line and easily coping with large orders.

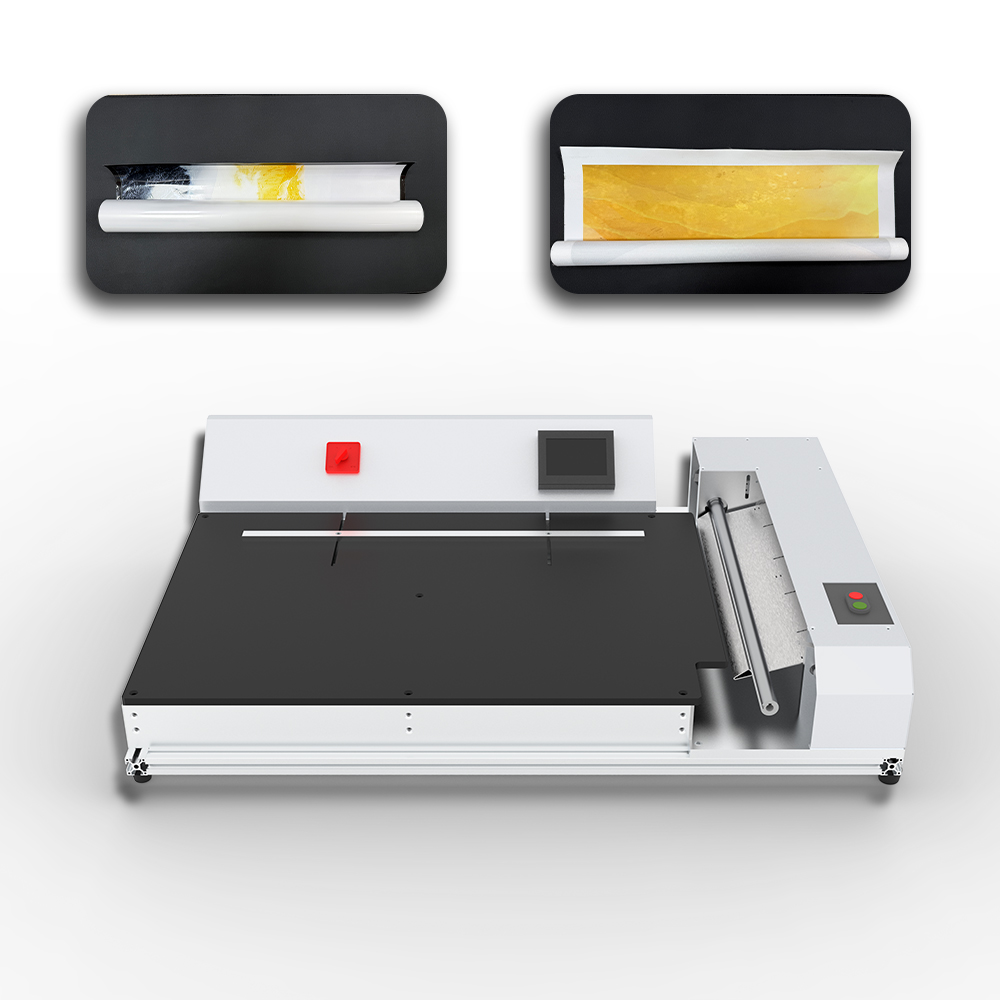

Feature 2: Precise control to ensure that each roll is perfect

Each component is designed around a specific purpose, such as the precision tension control mechanism and photoelectric deviation correction components. Tension, speed, and number of winding turns can all be adjusted by the operator through the PLC system using the designed touch screen interface.

Whether it is thin plastic film or thick EVA composite material, the edge is neat, tight, with no slack and no internal wrinkle after winding. The professional appearance of the product raises the product quality to a certain level, thus having a positive impact on the brand.

Feature 3: Wide adaptability, one machine with multiple functions, unlimited applications

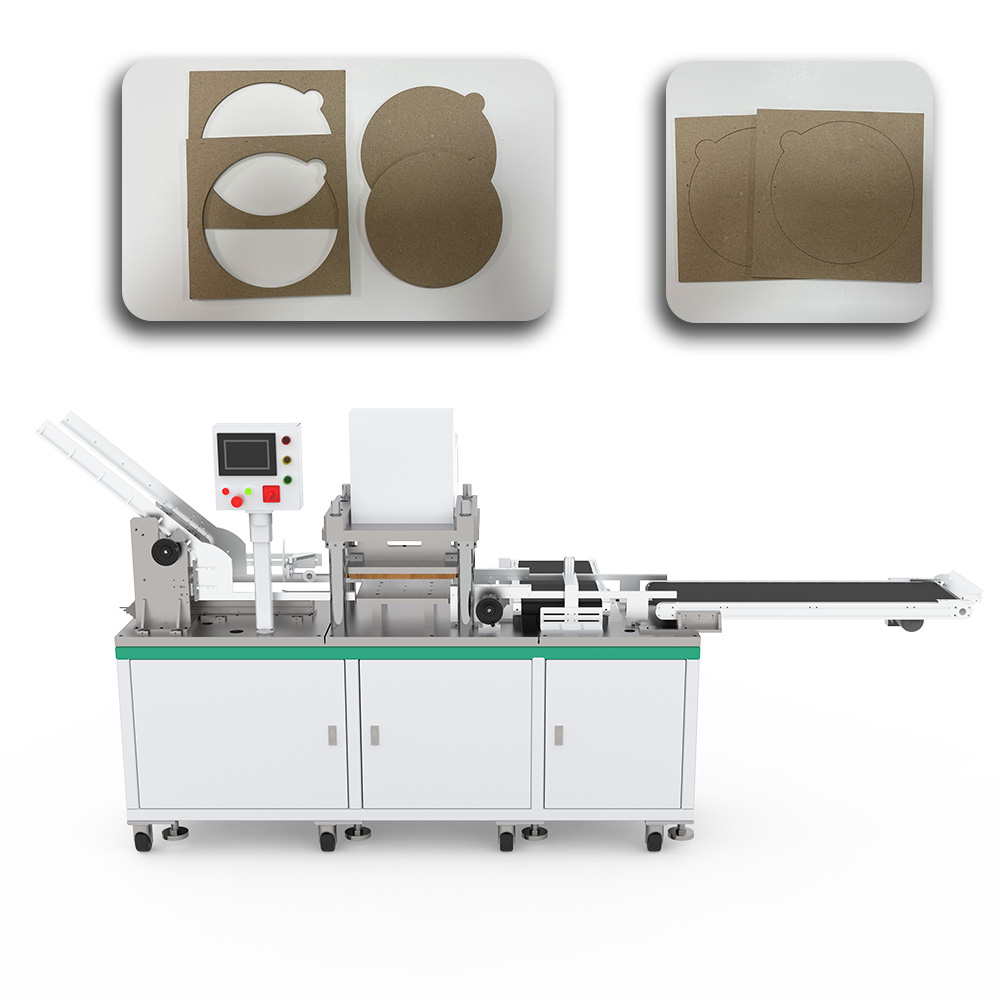

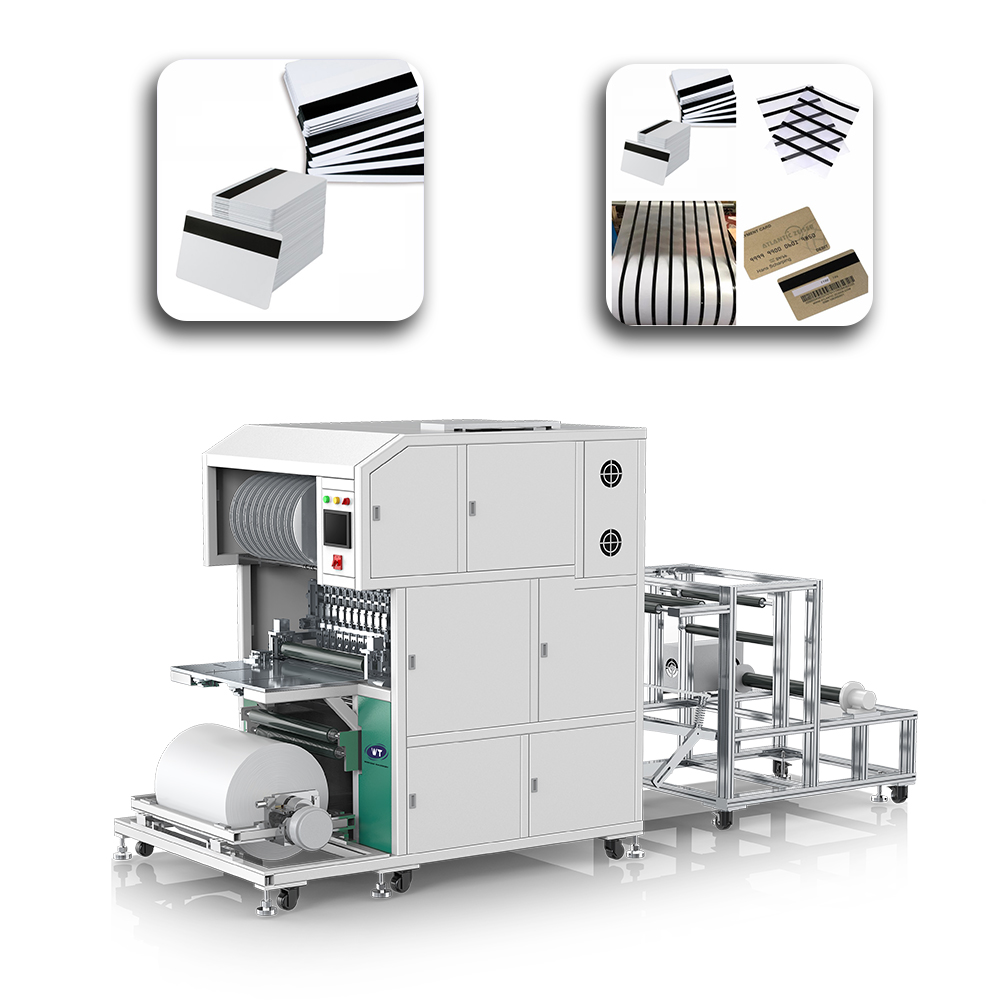

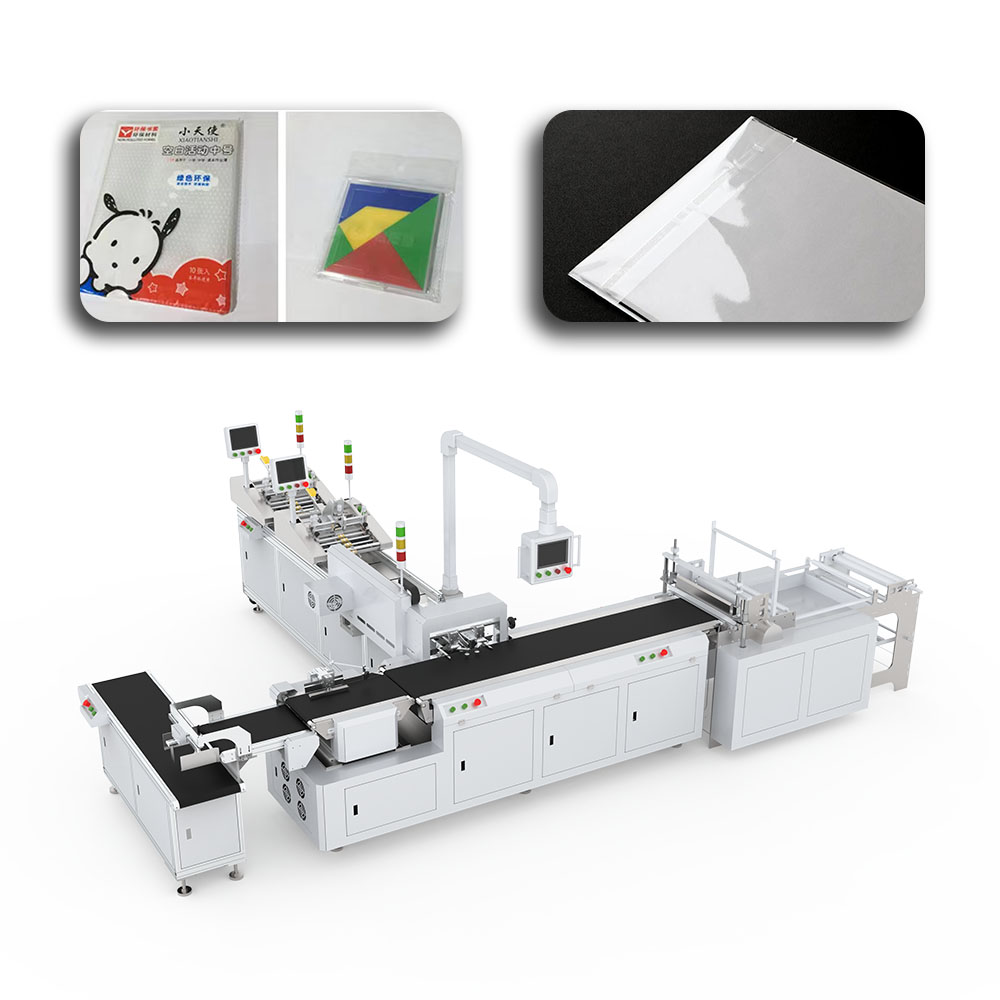

The paper roll machine has excellent versatility in terms of material and production material compatibility. It can efficiently process various flexible packaging materials and paper (coated paper, cardboard, kraft paper, aluminum foil), paper-plastic composite materials, aluminum-plastic composite materials, EVA foam, non-woven fabrics, and even plastic films (PP, PET, PVC, and other flexible packaging materials).

One machine can meet the production needs of various products such as posters, learning cards, advertising materials, software packaging, and home decoration coils. This saves you the cost of purchasing dedicated equipment for different materials and improves equipment utilization.

Feature 4: Easy to operate, quick to get started, and reduces training costs

We believe that the excellence and user-friendliness of equipment operation should be put in the first place. The simple and clear Chinese and English operation interface design, the logical arrangement of operation buttons, and the intelligent preset power scheme enable even novice operators to complete the work independently after simple training.

Value: This design minimizes the skill and training requirements for operators, solves the problem of “difficult recruitment and slow training” for many enterprises, and supports the continuous flow and operation of production.

Feature 5: Flexible winding mode to meet personalized order requirements

The equipment retains flexibility in winding one or more materials. Depending on the customer order specifications, it is easy to wind a single roll independently or to integrate multiple materials together (such as a set of series learning cards, supporting posters, and instructions).

The value brought: continuously improve the production flexibility, quickly respond to the personalized small-batch customized orders of customers, and enhance the market competitiveness.

3. Core technologies and applicable scenarios of the paper rolling machine

Core technology and configuration:

Drive system: High-precision servo motor, realizing seamless movement and precise positioning.

Control system: Industrial-grade PLC touch screen, with data storage and retrieval functions and shortcut keys to set programmable parameters, enhances the interaction between the human-machine touch screen operator and the PLC.

Tension control: The winding adopts magnetic powder brake or frequency converter stepless adjustment.

Main material: The equipment frame is made of high-strength steel, and the high wear-resistant parts are made of alloy or specially treated to ensure the long-term use of the equipment.

Target customer groups and applicable scenarios:

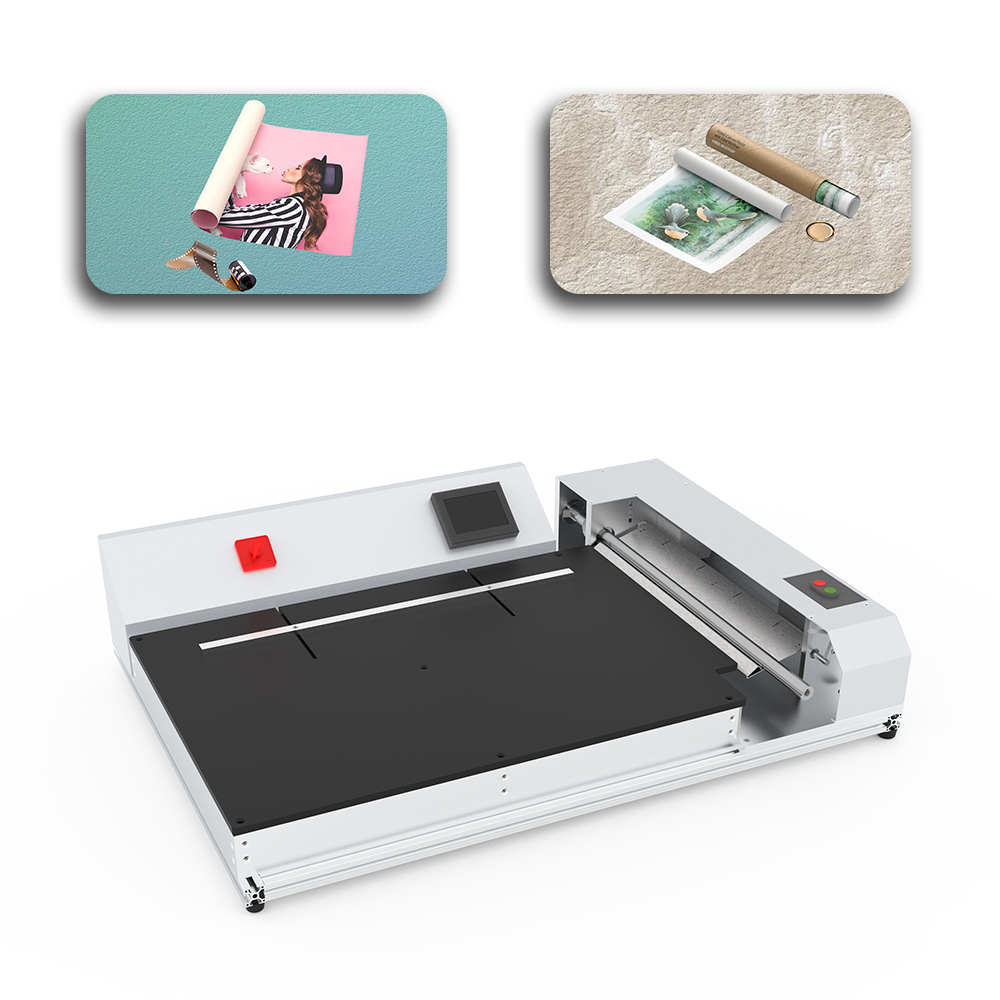

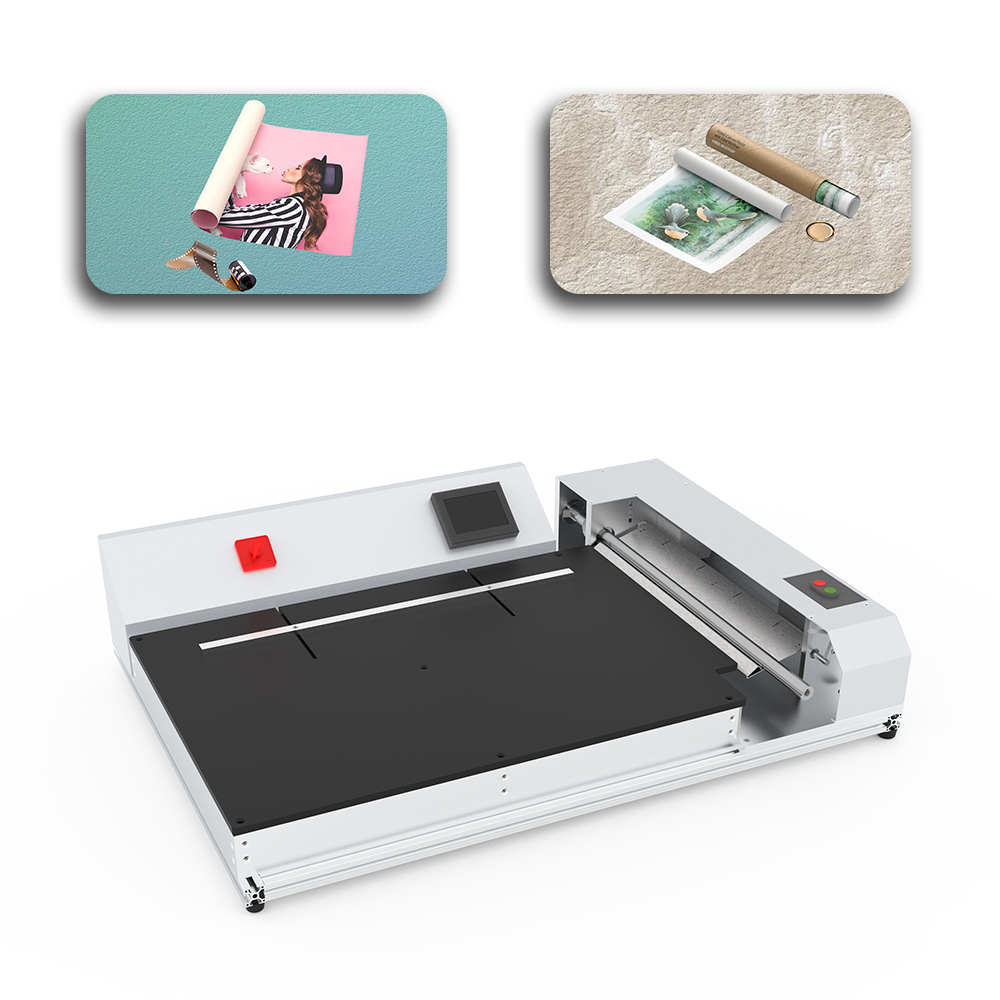

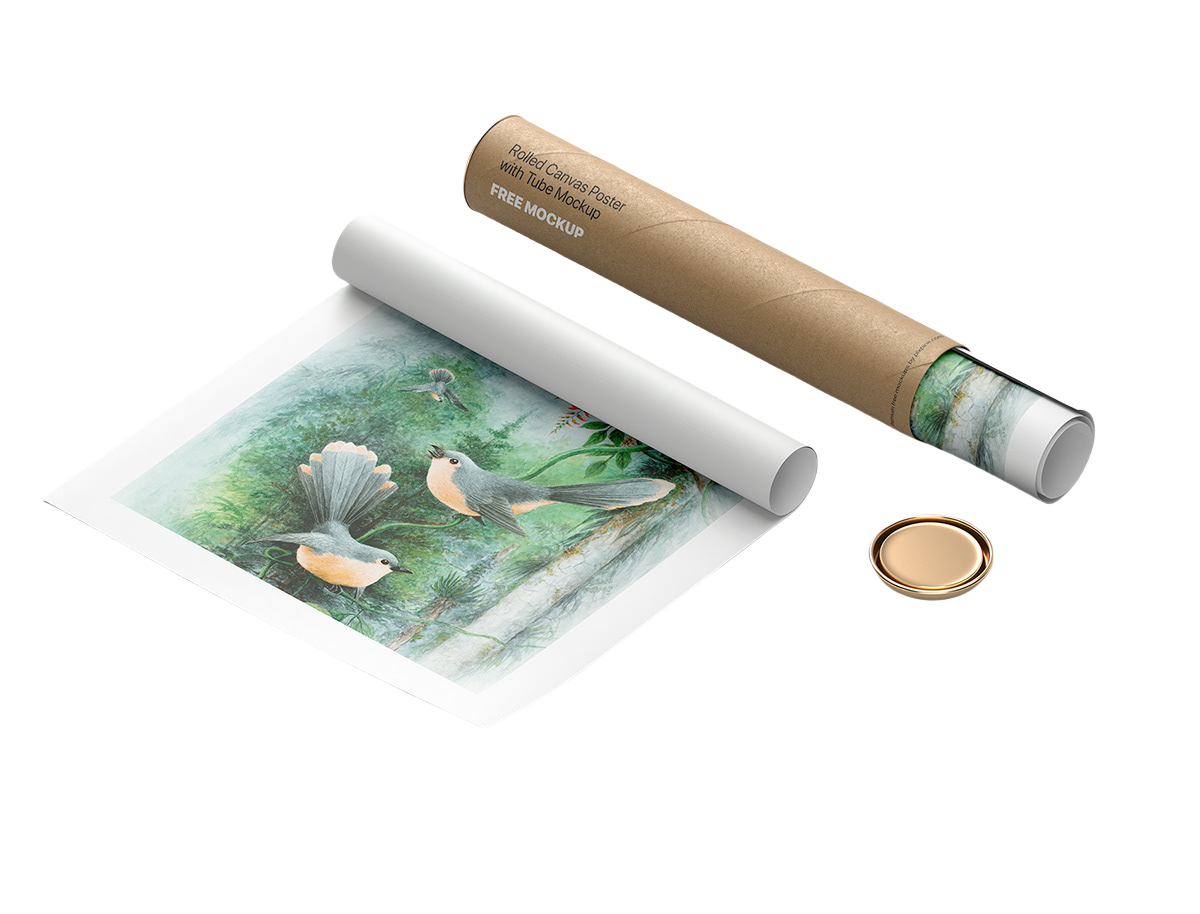

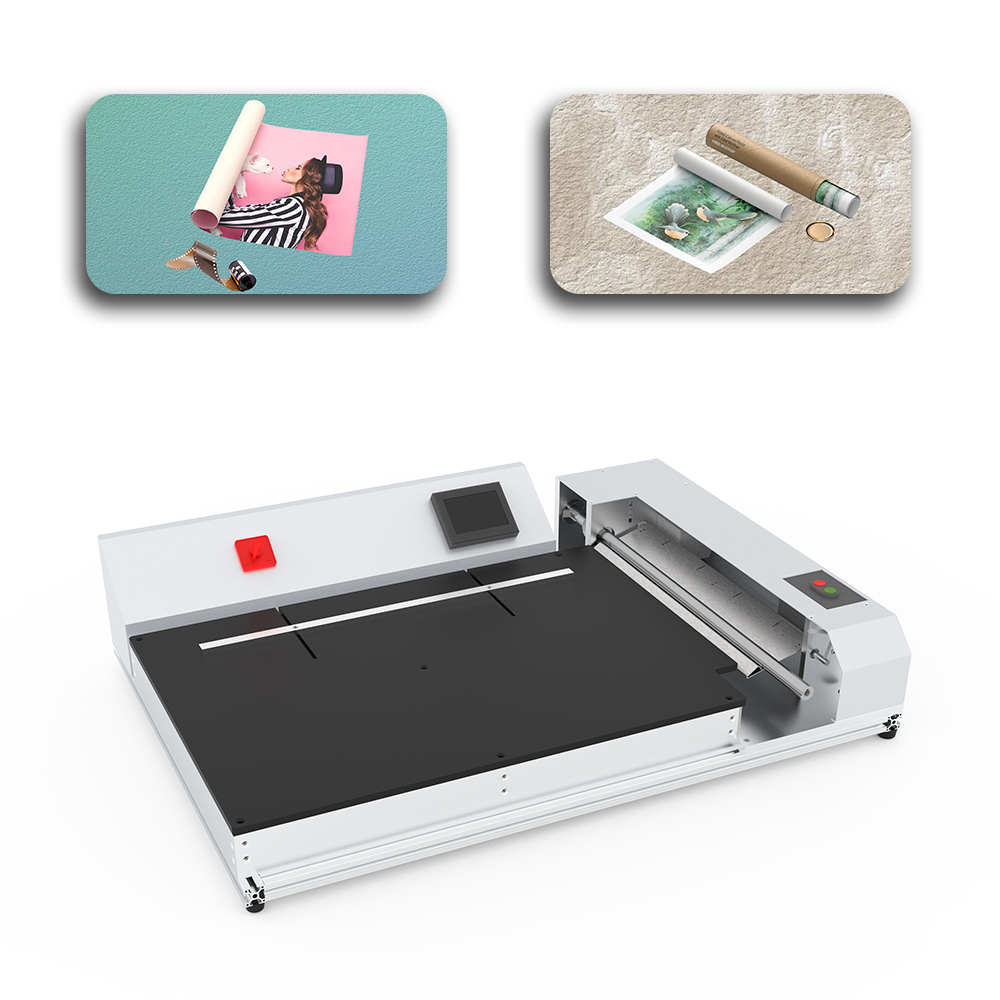

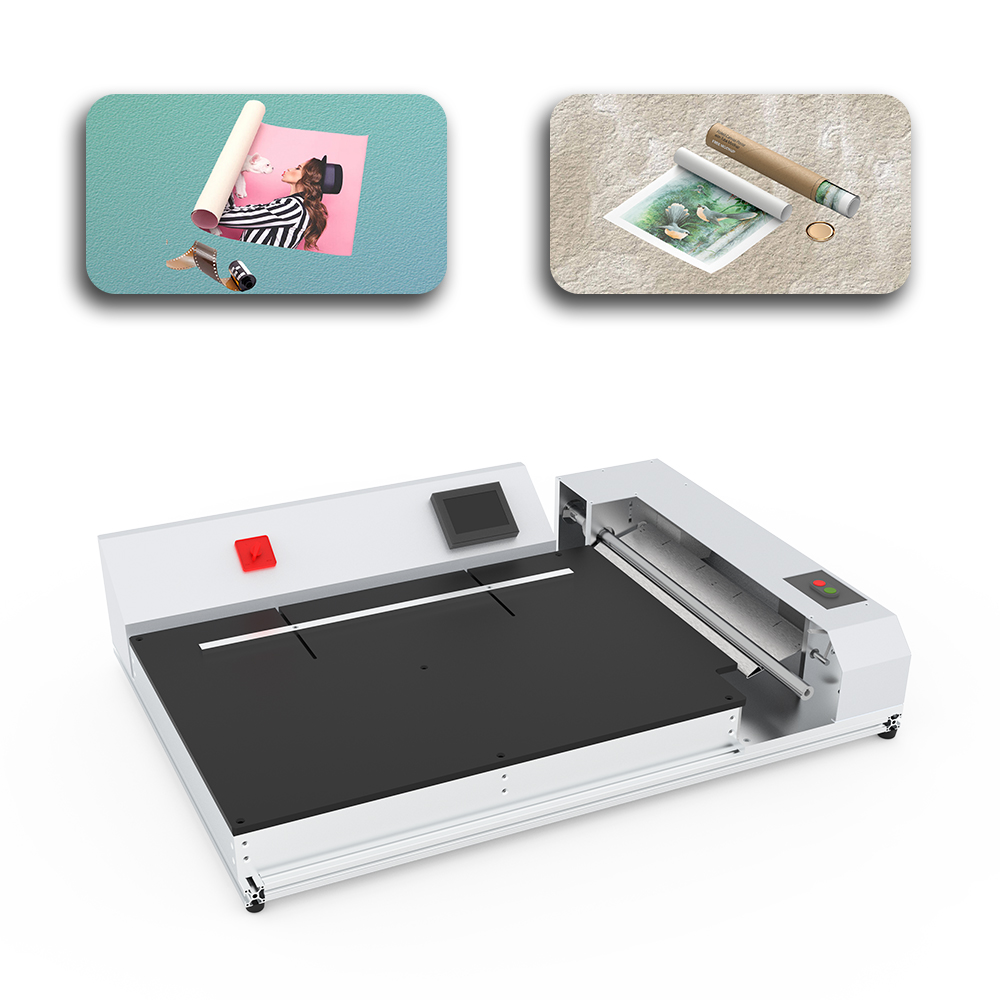

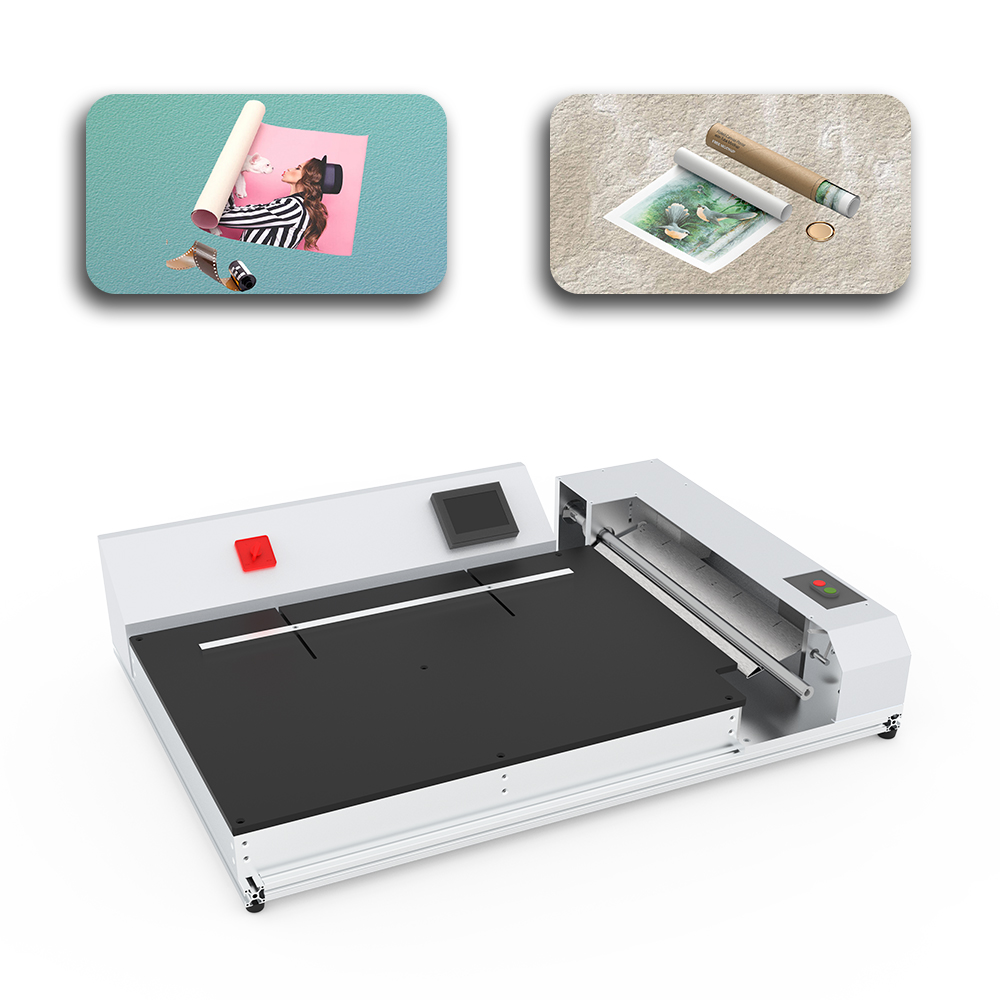

Printers and packaging companies: for books, posters, brochures, and gift wrapping paper.

Educational supplies and stationery manufacturers: automated production of learning cards, maps, and children’s enlightenment scrolls.

Advertising and display supplies companies: for processing large posters, roll-up banners, and exhibition scroll materials.

Composite material processing enterprises: used for slitting and rewinding flexible web materials (EVA, leather, or decorative materials).

4. Why choose Wintone?

Quality assurance: We have fully introduced the ISO quality management system. All processes are quality controlled to ensure that all paper roll machines delivered to you are stable and reliable.

Excellent value for money: Thanks to the advantages of local manufacturing and supply chain integration, we are able to deliver high-quality equipment with a value for money that far exceeds that of international competitors.

Global service and support: We guarantee that your equipment can operate efficiently anywhere in the world through a complete overseas after-sales service network, including professional installation guidance, operation training, online technical support, and rapid delivery of spare parts.

Conclusion

In today’s age of intelligence, a high-performance rewinder is more than just a new piece of equipment; it is a new, reliable, and precise production method for your organization. A rewinder is a tactical response to increasing labor costs, increased finished product value, and enhanced manufacturing capabilities.