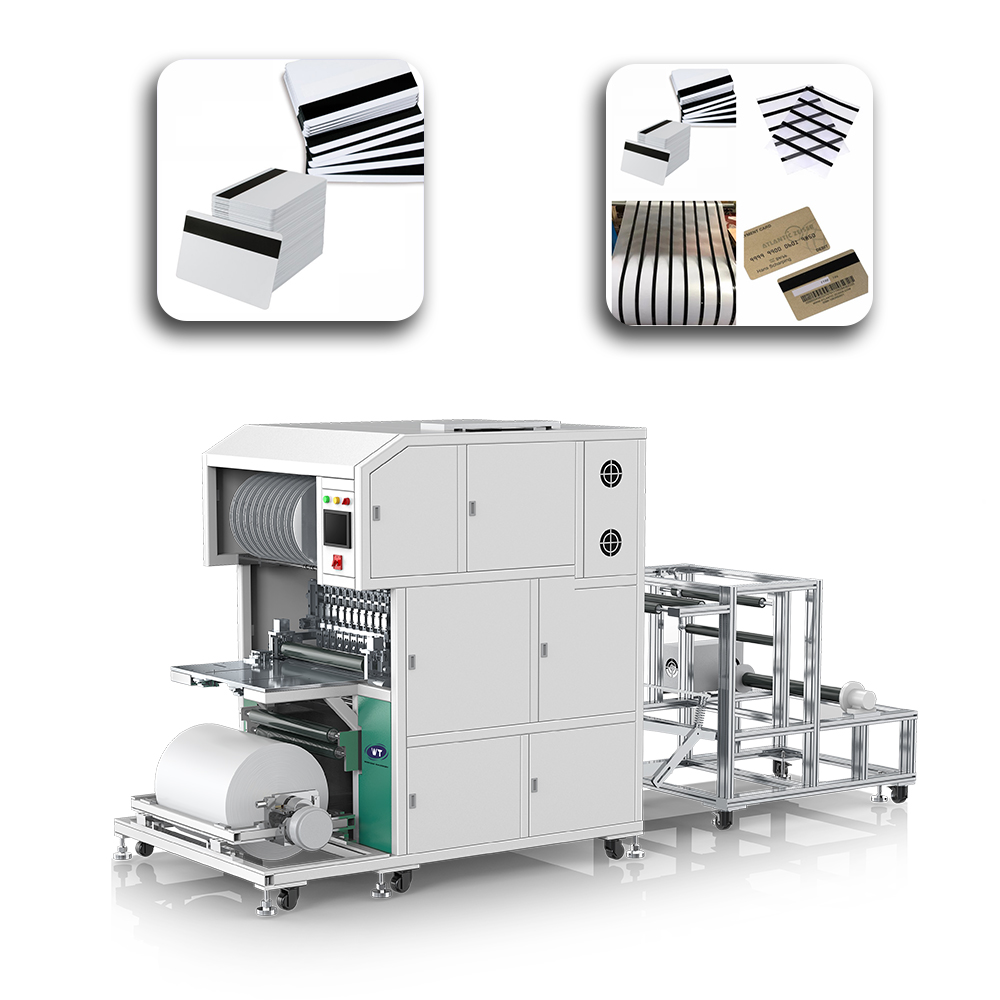

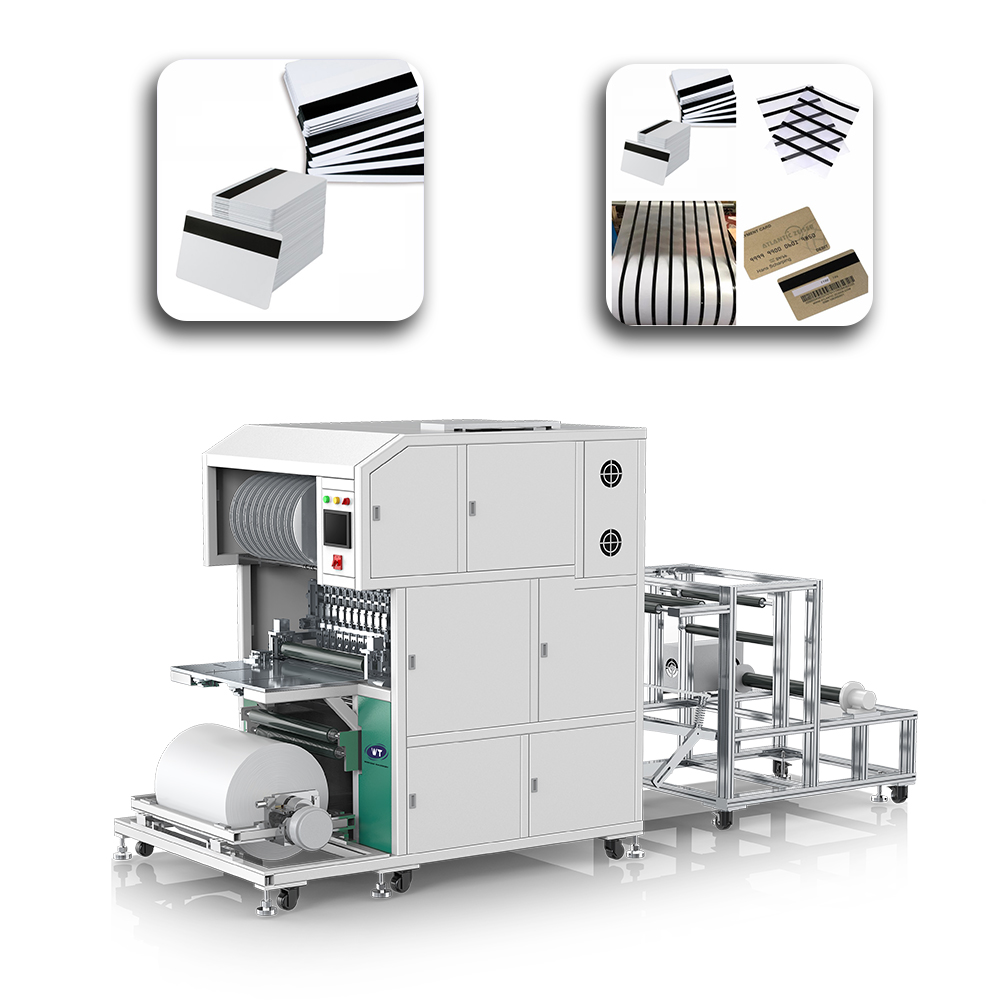

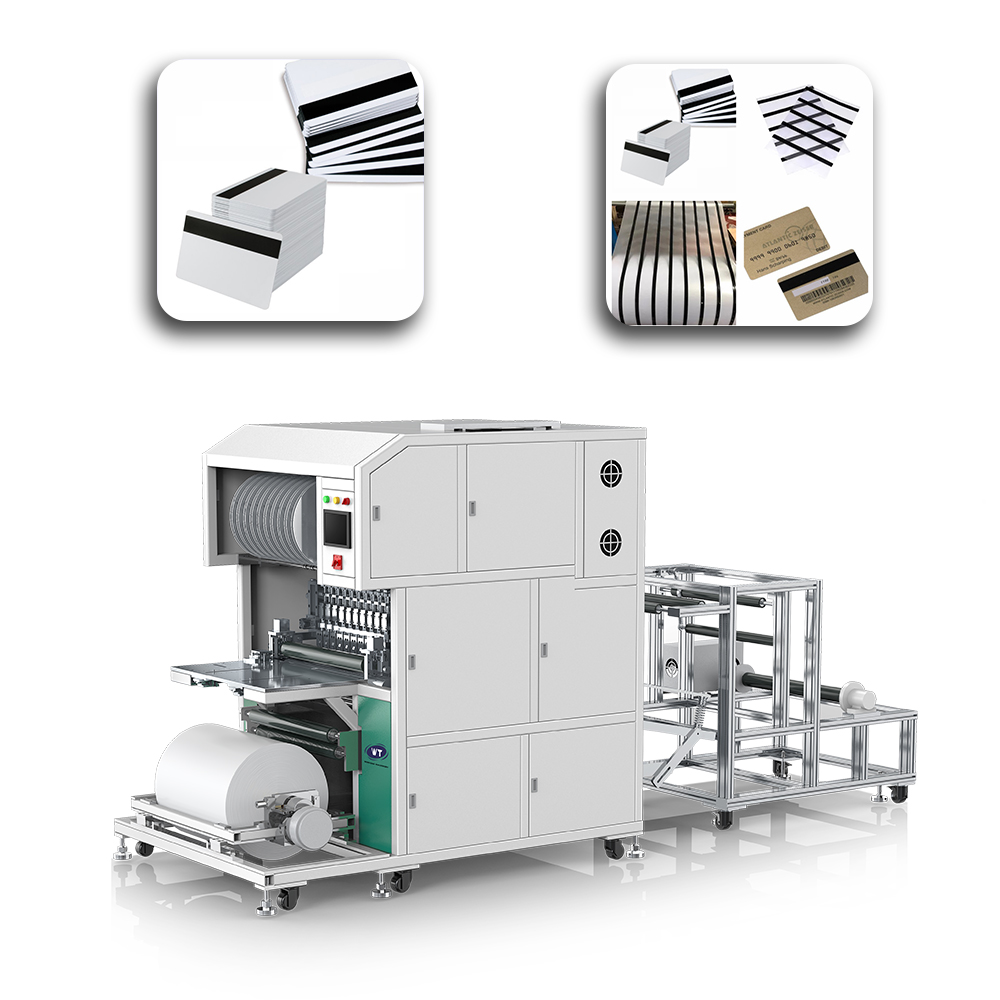

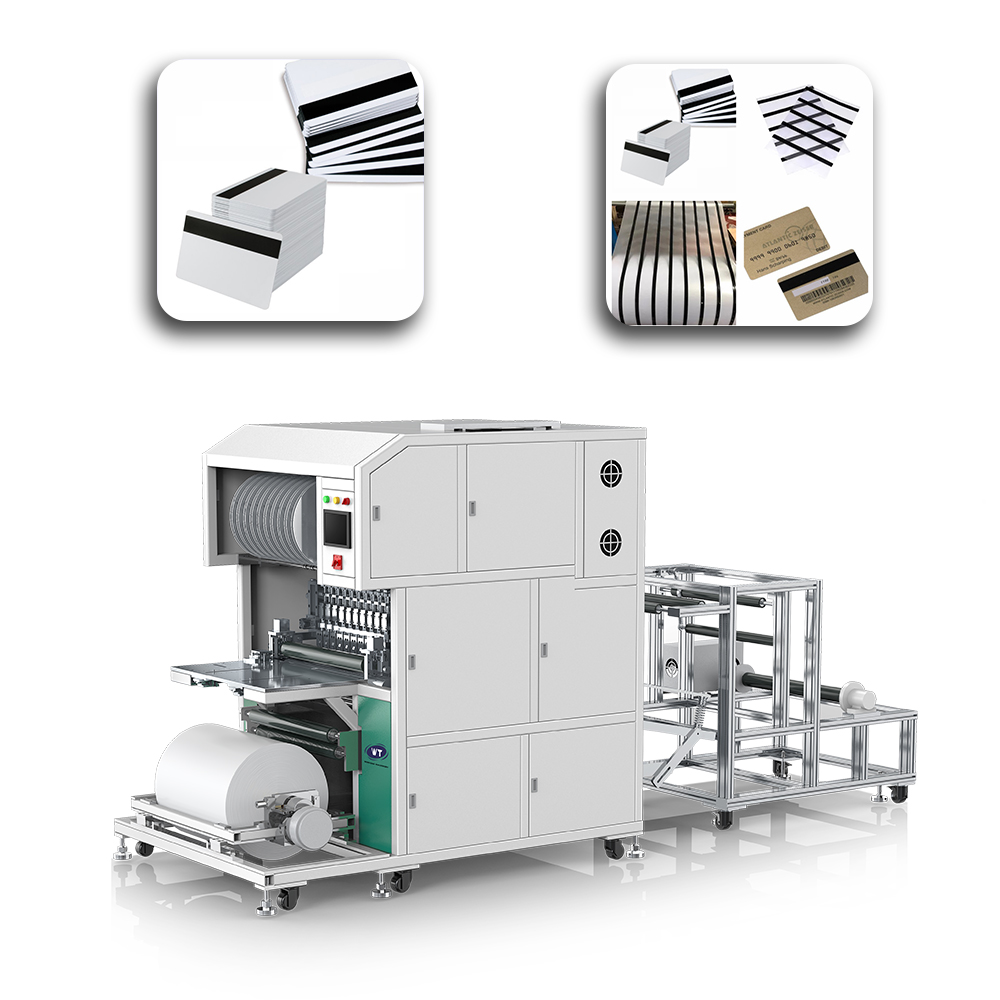

In the global card production, the quality of the product depends on the accuracy of the card magnetic stripe welding and cutting. For example, paper anti-counterfeiting labels, PET membership cards, PVC financial cards, etc. all require reliable mechanical equipment. The Shenzhen-made fully automatic high-precision magnetic stripe card machine has seven core advantages, is sold all over the world, and is the main production machine for card-making enterprises.

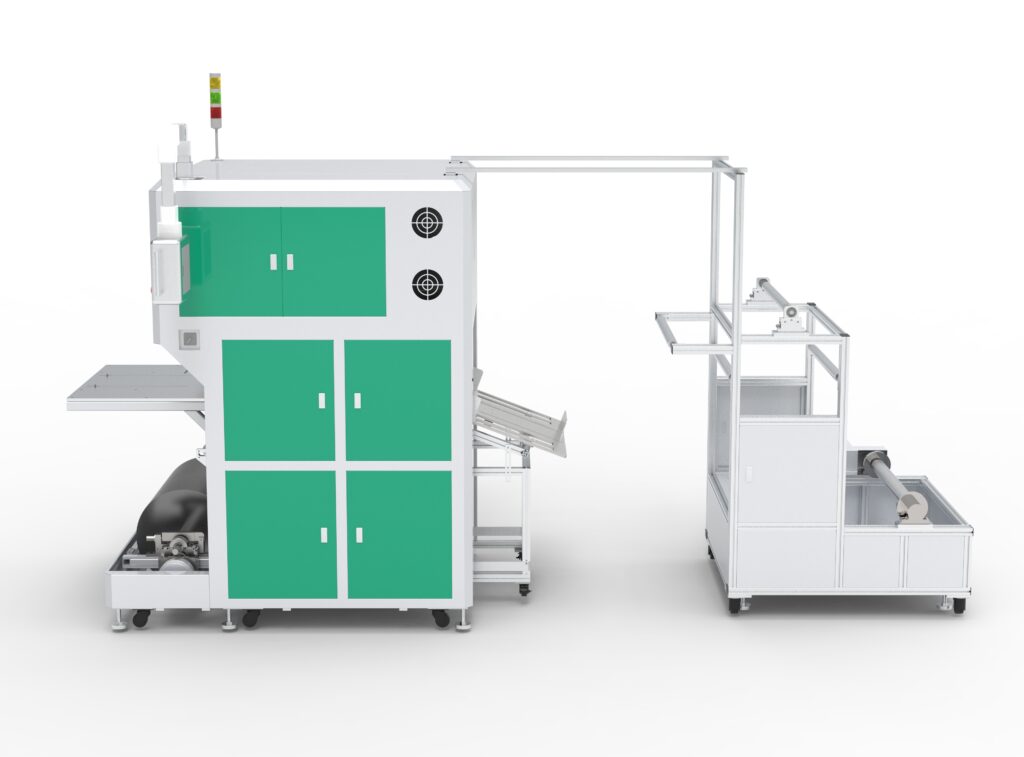

As a research and development manufacturer in Shenzhen, we responded to the needs of overseas markets and developed this magnetic stripe machine after several iterations. It mainly welds the magnetic stripe stably on the base material of the card, and the material can be PET, PVC, paper, etc., and performs synchronous precision cutting. All the processes are automated. Previously, they were done manually, which was inefficient, inaccurate, and had a high defect rate. Now, all these problems have been solved.

Product parameters

| Power supply |

AC 380V/50 HZ |

Format |

3X8/4X8/5X5/5×6/8×8 optional |

| Total power |

2.5KW |

Control |

PLC control + servo system |

| Air source |

6 kg/cm2 |

Operators needed |

1 |

| Air consumption |

Approx. 80L/min |

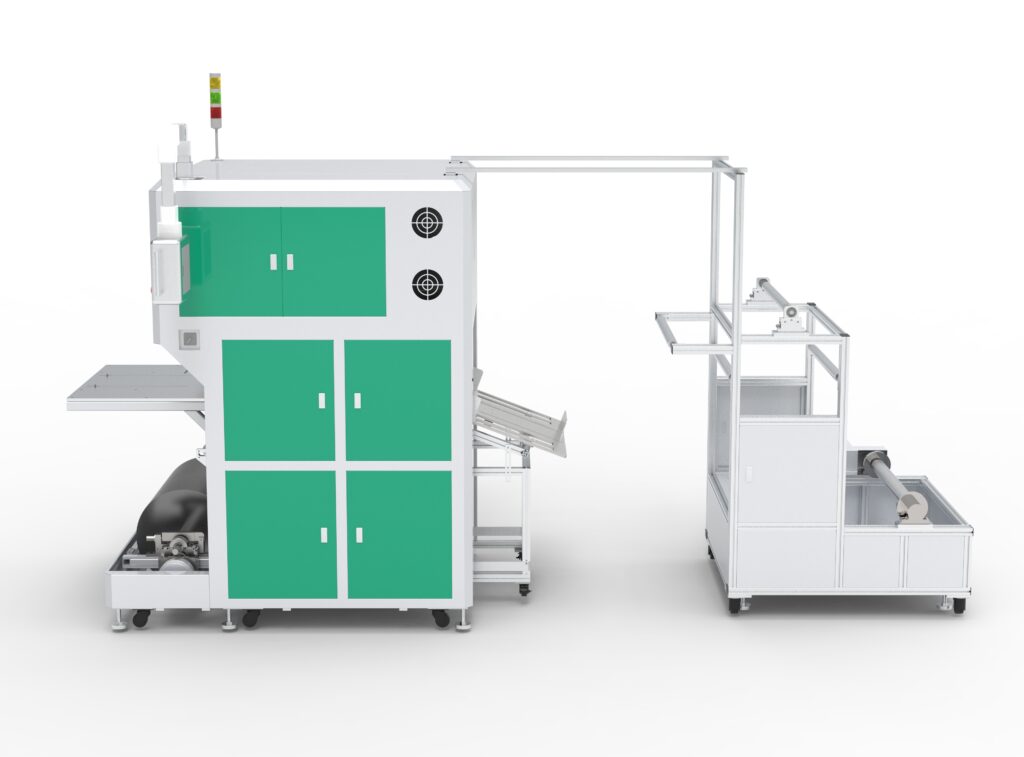

Dimension |

L2250*W1000*H1700MM |

| Laying accuracy |

±0.15mm |

Product thickness |

0.2mm~1.0mm |

| Temperature control accuracy |

±2℃ |

Temperature control range |

0~400℃ |

| Magnetic tape width |

6.35mm/8.4mm/12.7mm |

Quantity of magnetic tapes |

5~12 |

| Applicable materials |

Paper card, PVC, ABS, PET, PVC/ABS composite materials, etc. |

Productivity |

900 Sheet/H |

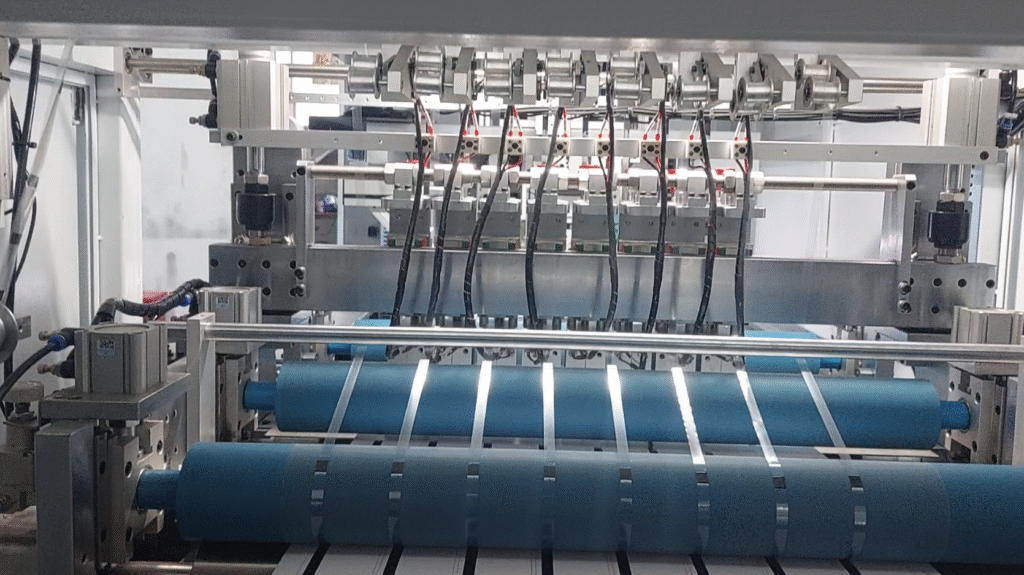

Precise control of the servo motor of the magnetic stripe machine

The magnetic stripe machine is driven by an imported servo motor, which has a stable and accurate function. The running speed and feeding speed can be adjusted steplessly from 0.5 to 5 m/min to meet the processing needs of different materials. Through servo closed-loop control, the feeding length error is controlled within ±0.1 mm, which reduces the rework cost and consistency of mass production.

The intelligent temperature control of the magnetic stripe machine is accurate and stable.

In terms of welding quality, advanced and precise temperature control is the key. The magnetic stripe machine adopts a complete set of imported temperature control systems and adopts a heating tube, a German PT100 temperature probe, and a PLC intelligent temperature control module for advanced temperature control. The adjustable temperature range is 50-300℃, and the temperature control accuracy is ±1℃. It can ensure the firm adhesion between the magnetic stripe and the substrate. It can also prevent the substrate from deforming and the magnetic stripe from being damaged and process heat-sensitive materials such as PET.

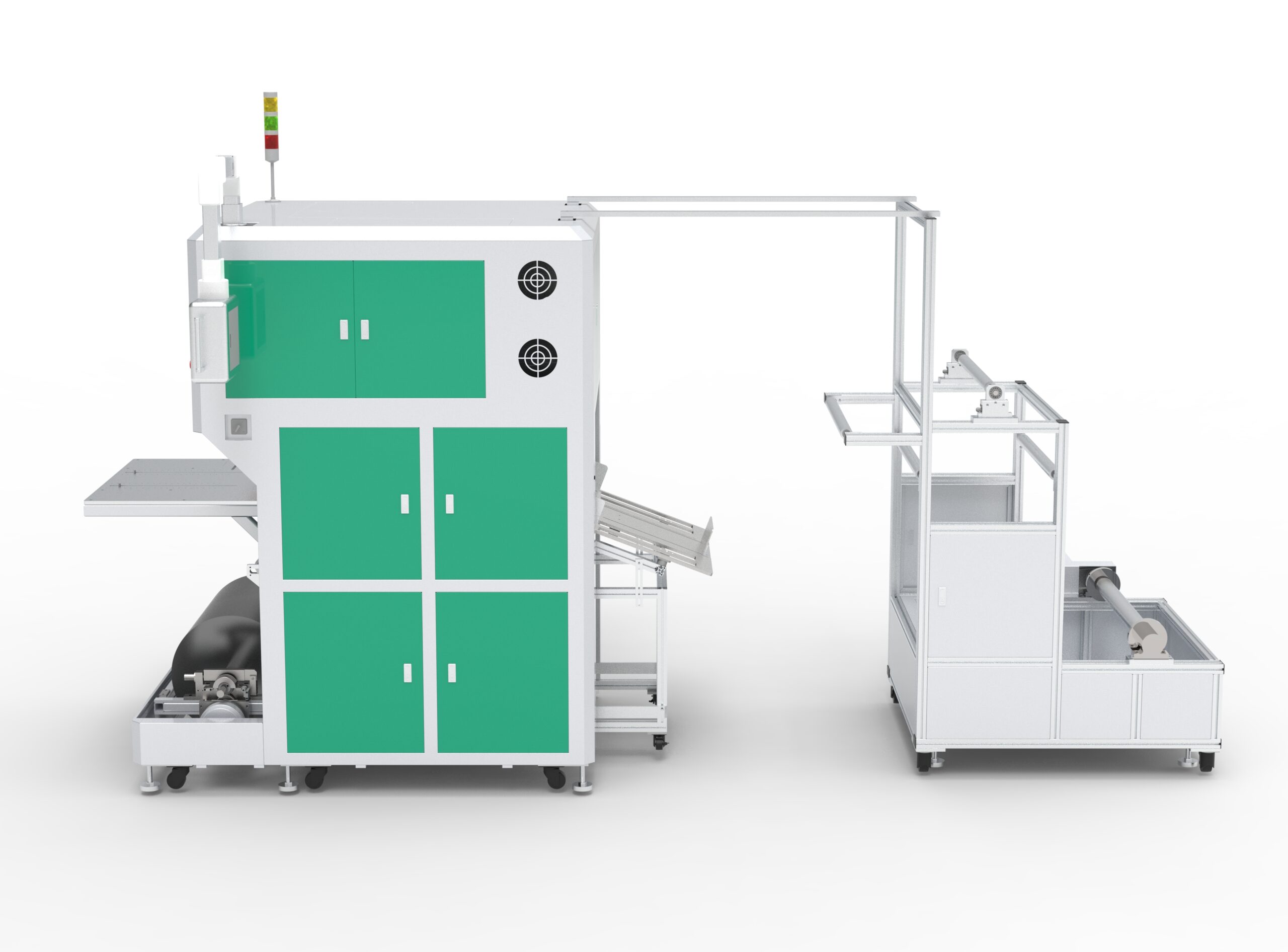

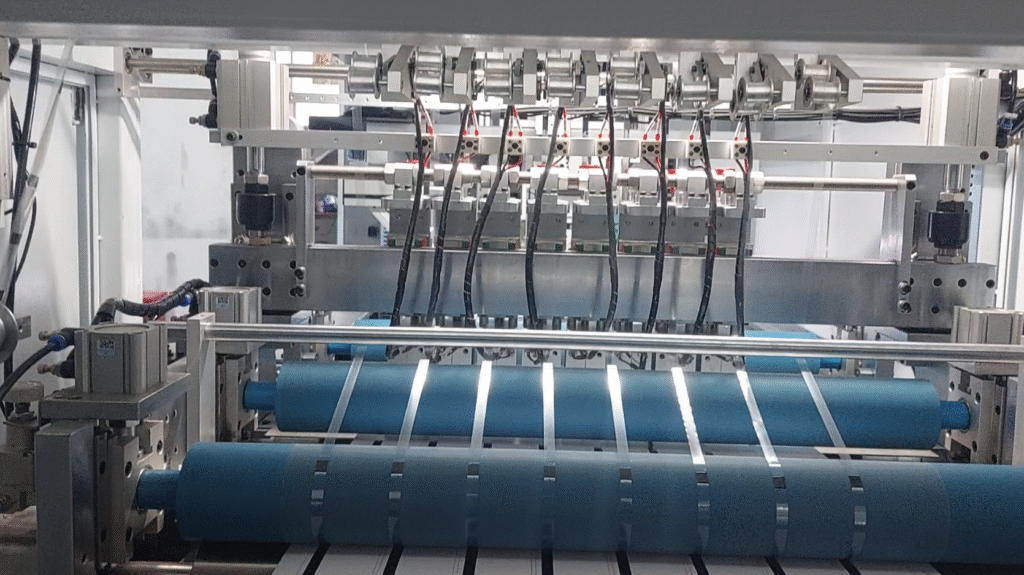

Independent adjustment design

Each magnetic head can be individually adjusted for temperature and pressure. The basic configuration includes three magnetic head groups, which can be expanded to eight. Each magnetic head group has a pressure control of 0.1-0.5 MPa, and the temperature can be set independently. Synchronous welding of magnetic strips of different sizes and materials can be realized, which helps multi-variety production enterprises optimize equipment efficiency and improve site utilization.

Welding quality

The magnetic stripe machine is designed for stable welding. Aging treatment eliminates welding deviation caused by vibration. The magnetic strip is completely attached to the substrate because the silicone pressure wheel is customized for each magnetic strip. The magnetic strip is equipped with a detection sensor to monitor the position deviation in real time, and the alarm is shut down.

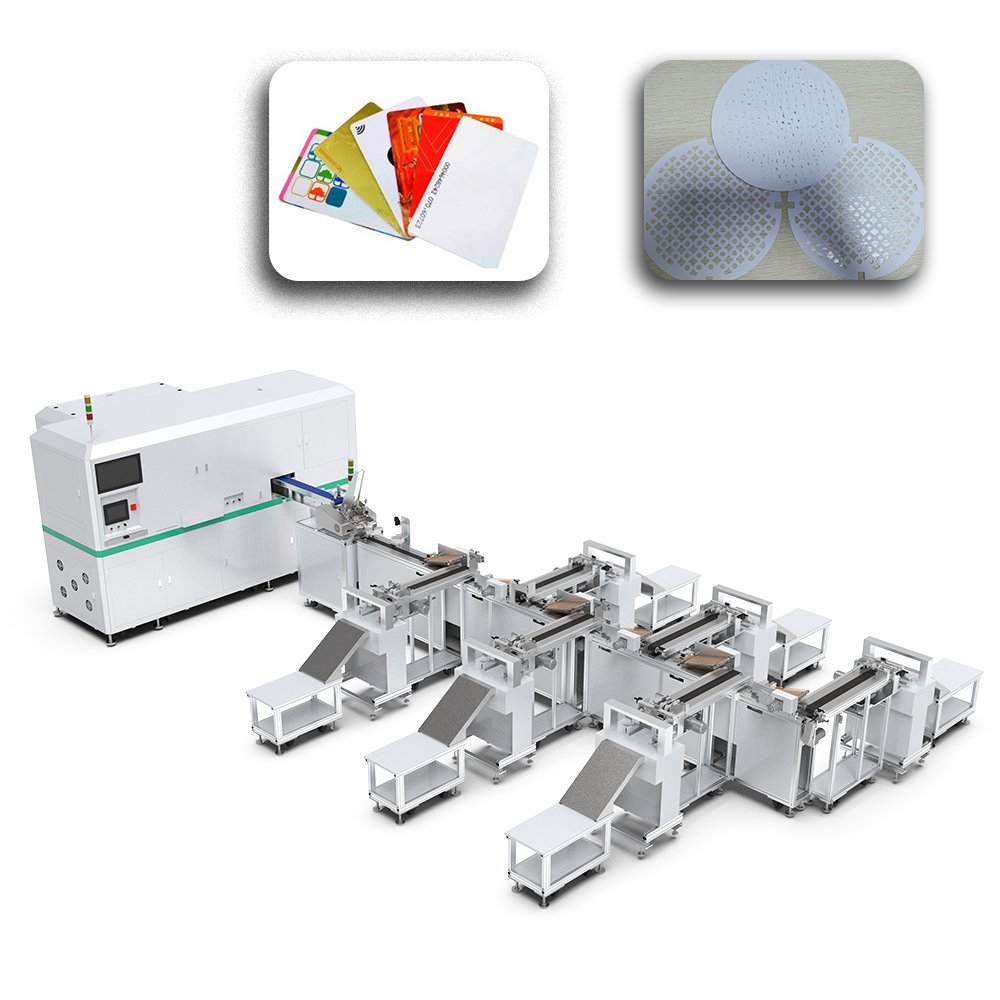

Widely used in full-scene processing

The magnetic stripe machine has good compatibility. For materials, there is no need to change the mold for 0.1-0.5 mm PET, 0.2-0.8 mm PVC, and 120-300 g paper cards. High- and low-coercivity magnetic strips with a width of 2-20 mm and a thickness of 0.05-0.2 mm can also be produced. The adjustable card entry slot with guide can handle standard 85.5 x 54 mm cards as well as large custom cards.

One-stop production of automated operations

The fully automated design of the card magnetic stripe machine runs through the entire production process, truly realizing “one-button start, worry-free throughout the process.” The magnetic stripe machine is equipped with an automatic feeding mechanism, which can accommodate 500 cards/batch of card blanks, and automatically complete the feeding, positioning, conveying, and other processes; the magnetic stripe unwinding adopts an automatic tension control system to avoid stretching or wrinkling of the magnetic stripe due to uneven tension; after the welding is completed, the equipment automatically switches to the cutting process without manual transfer of materials. The entire processing process requires only one operator to complete parameter settings and material replenishment. Compared with the traditional manual processing mode, the production efficiency is increased by more than 60%, and the labor cost is reduced by 70%. In addition, the equipment is also equipped with an intelligent silo, which can realize 24-hour continuous operation and meet the needs of large-scale batch production.

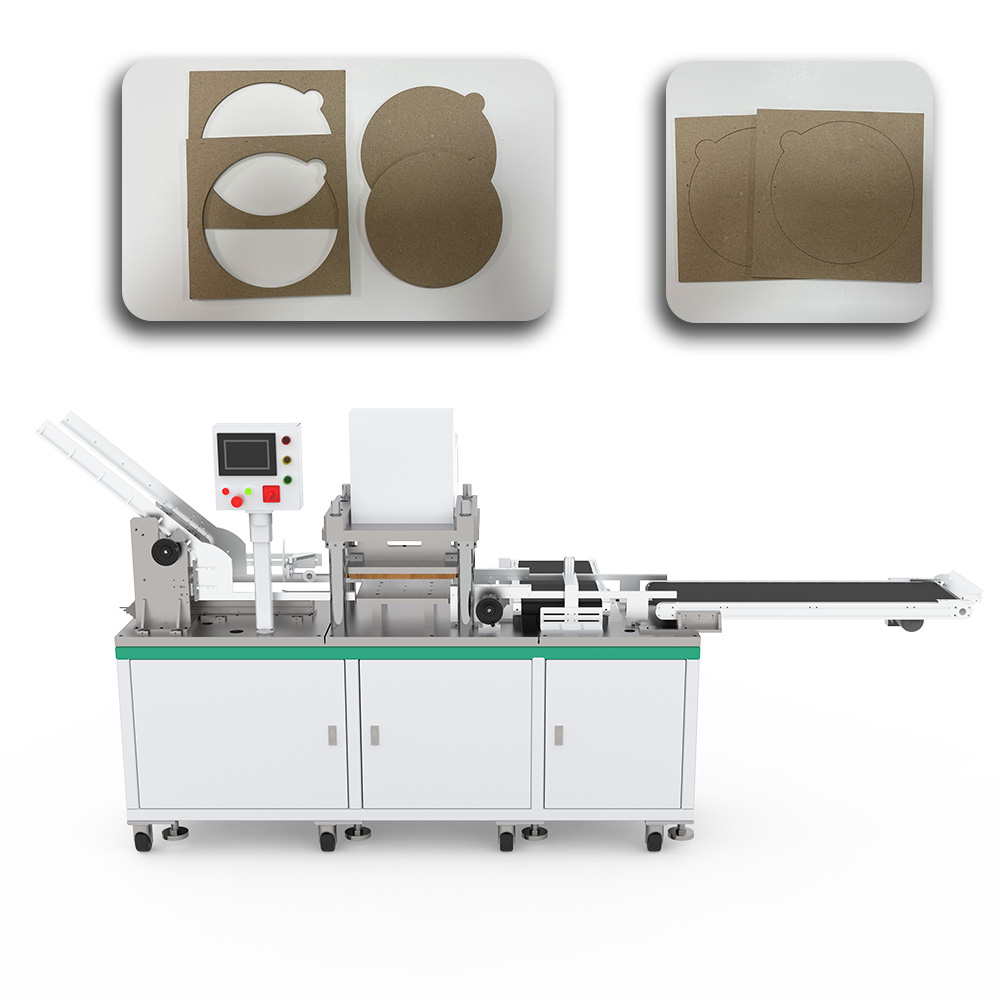

Precision cutting, no defective products

The quality and function of the card depend on the accuracy of the cutting. The magnetic card slitter adopts a high-speed precision blade slitting system. The system is equipped with a servo motor to achieve the best precision log cutting. The equipment can maintain a cutting error of ±0.05 mm. The cutting surface is flat and smooth, without cutting surface defects such as bubbles and burrs. The cutting blade is made of high-speed tungsten steel, which can maintain the cutting edge for 100,000 cuts. This blade has a long life, reducing the number of blade changes and thus reducing production costs. The blade has a constant automatic grinding function, and the focus is on the maintenance of the blade cutting edge. For customers with specific requirements for the length of the magnetic strip, the required length can be entered on the touch screen, and the system electronically adjusts the cutting parameters. The length range is between 10 and 100 mm.

Company strength

Precision machining, a perfect quality inspection system, and a 10,000-square-meter production base provide a guarantee for the equipment to pass ISO9001, CE, and UL certifications and meet overseas standards. Overseas service centers have been established in Germany, the United States, and Japan to provide 24-hour technical and maintenance support. For overseas use, customized 110V/220V voltage versions and multi-language operating systems are provided.

Applicable scenarios

Magnetic stripe machines can be used in industries such as finance, retail, transportation, and security and can be used to make credit cards, membership cards, bus cards, etc. The high cost performance and compatibility help small and medium-sized processing plants to expand their product range and face multiple industries, while large enterprises can stably meet their needs for mass production. The equipment has been exported to more than 50 countries and regions and has won a good reputation in different international markets.

Buying a Shenzhen card magnetic stripe machine is buying a technology-driven enterprise. To improve the efficiency of magnetic stripe processing, we will continue to provide overseas customers with more technologically advanced card magnetic stripe machines. For parameter details, customized solutions, or prototype testing, we encourage you to contact our global sales team.