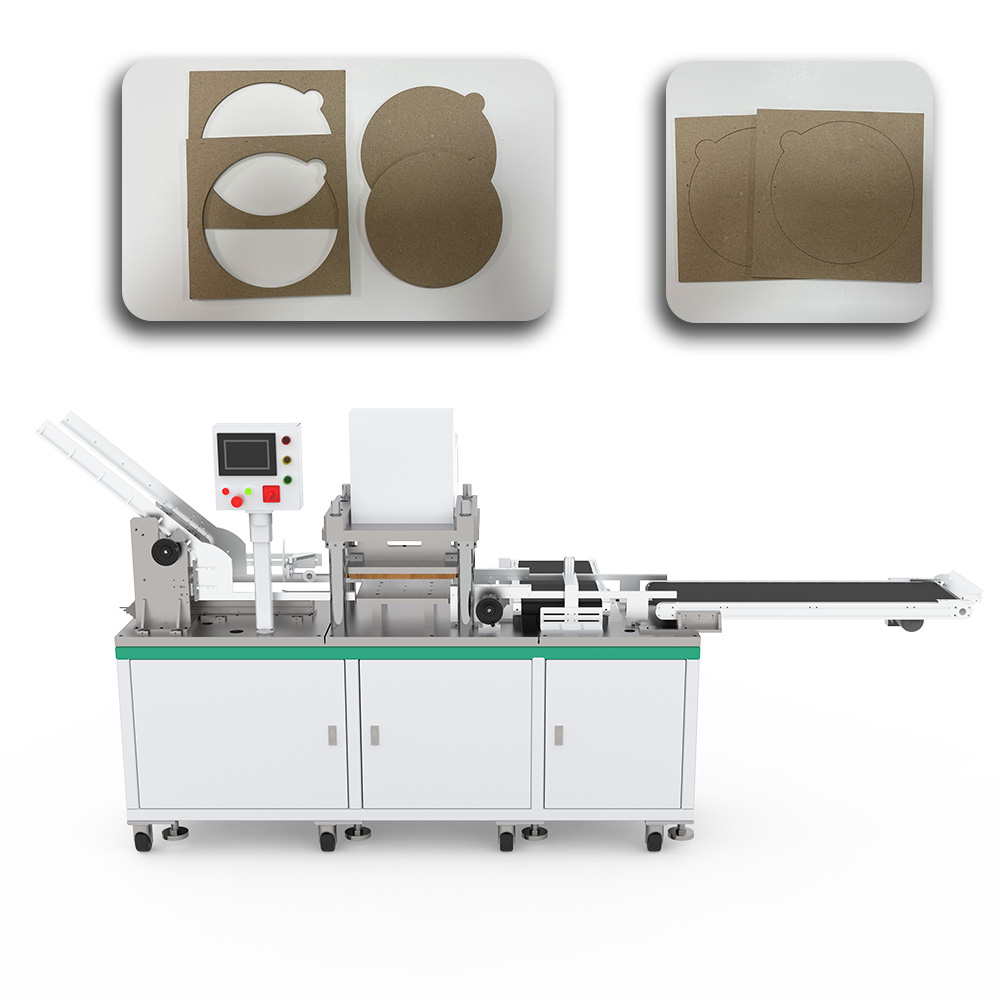

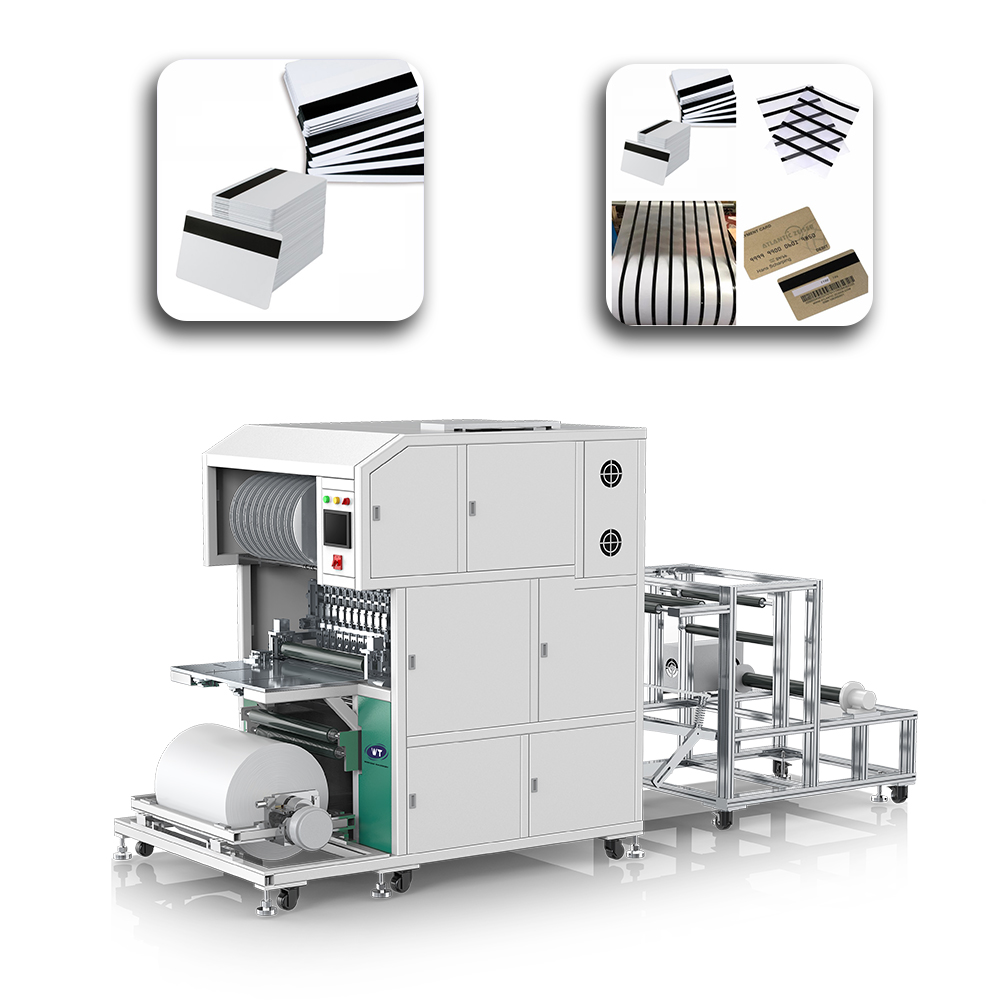

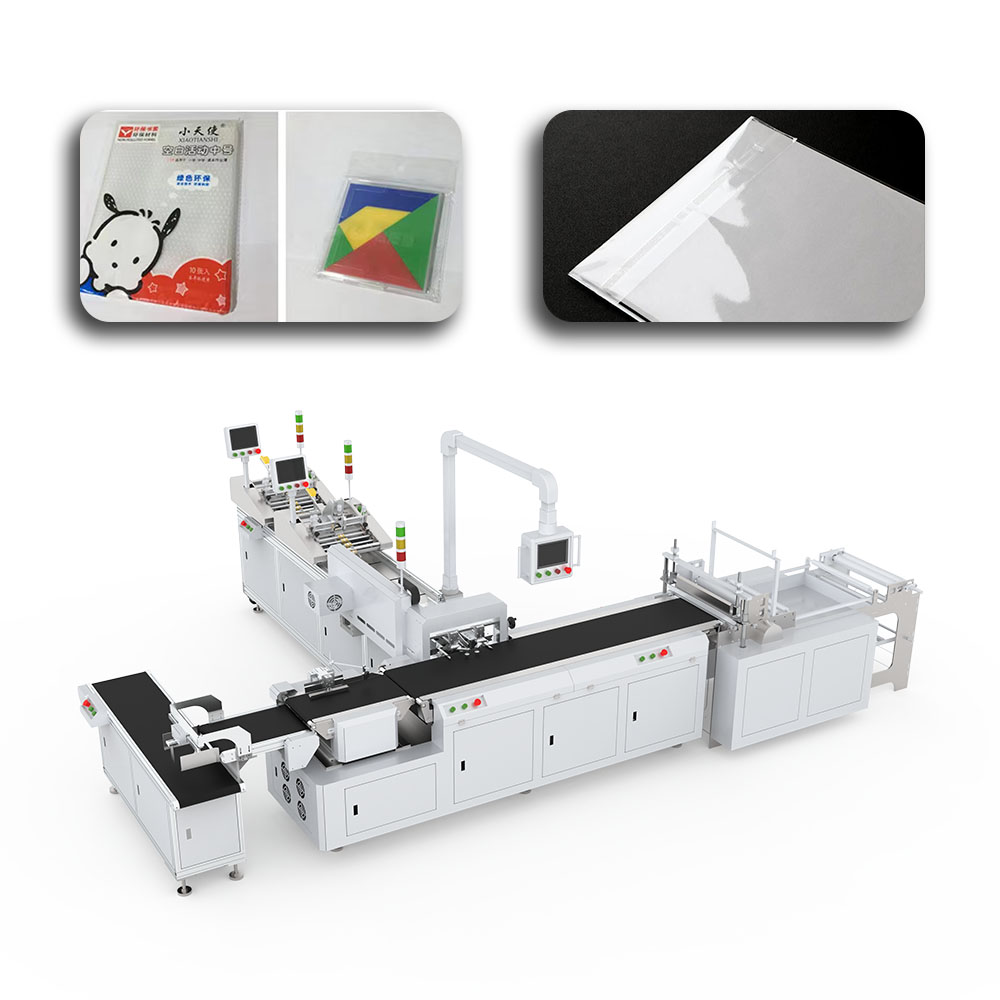

The game card punching machine is advanced professional equipment integrating efficiency and precision, which is specially designed for the card production and filter paper processing industries. The game card punching machine adopts integrated technology, and the punching process of different materials can be completed in one production run. It is widely used in the production of game cards, membership cards, smart cards, oil filter paper, steamer paper, coated paper, filter paper, and other special papers.

The core characteristics of the game card punching machine

1. Precision punching process

The game card punching machine adopts a customized stamping die and advanced pressure control system, with high precision. The accuracy of each punch can reach the micron level, and the punching surface is flat, smooth, and burr-free. Especially for the edge treatment of high-end cards and filter paper, it can meet the strict edge finish requirements in the industry.

2. Multifunctional application ability

One card punching machine meets various production needs:

Cards: game cards, membership cards, smart cards, plastic cards

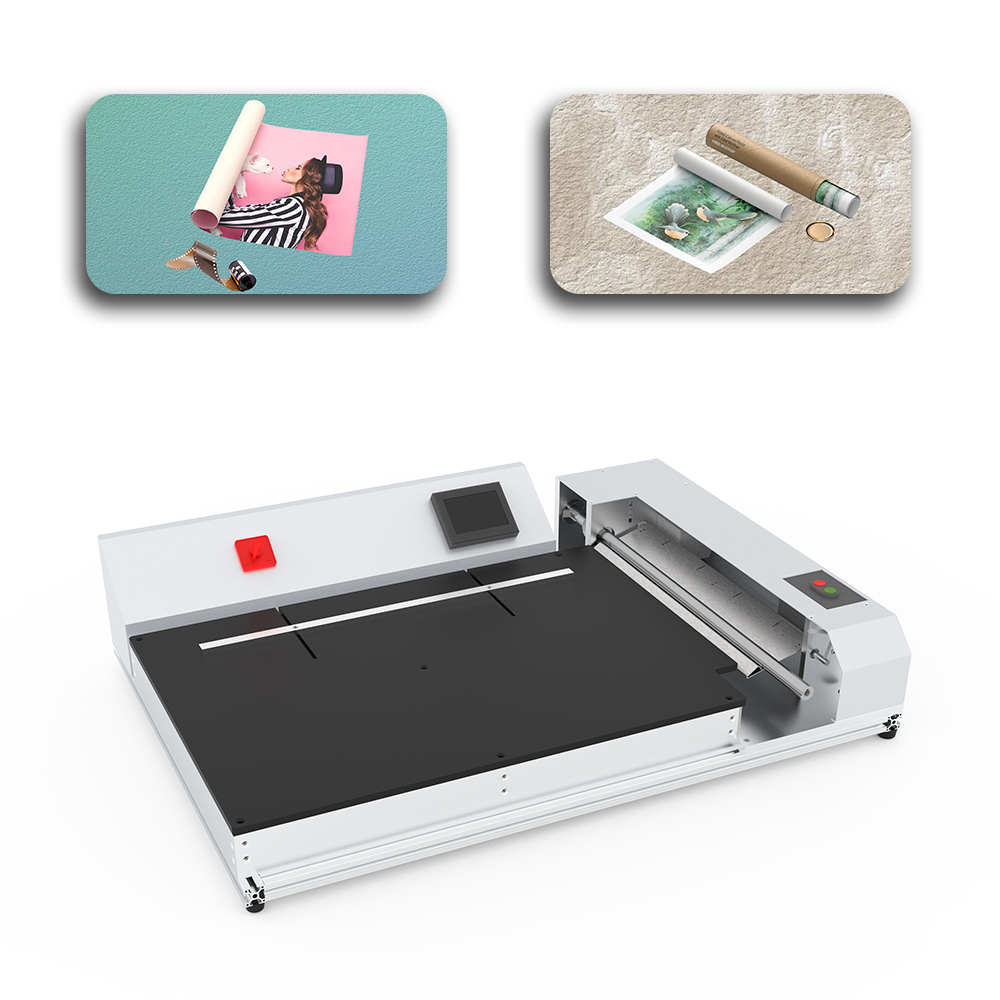

Paper products: calendars, books, brochures, document bags, envelopes

Special paper: oil filter paper, steamer paper, coated paper, filter paper

The game card punching and cutting machine is multi-purpose, which improves the frequency of equipment use and the flexibility of production.

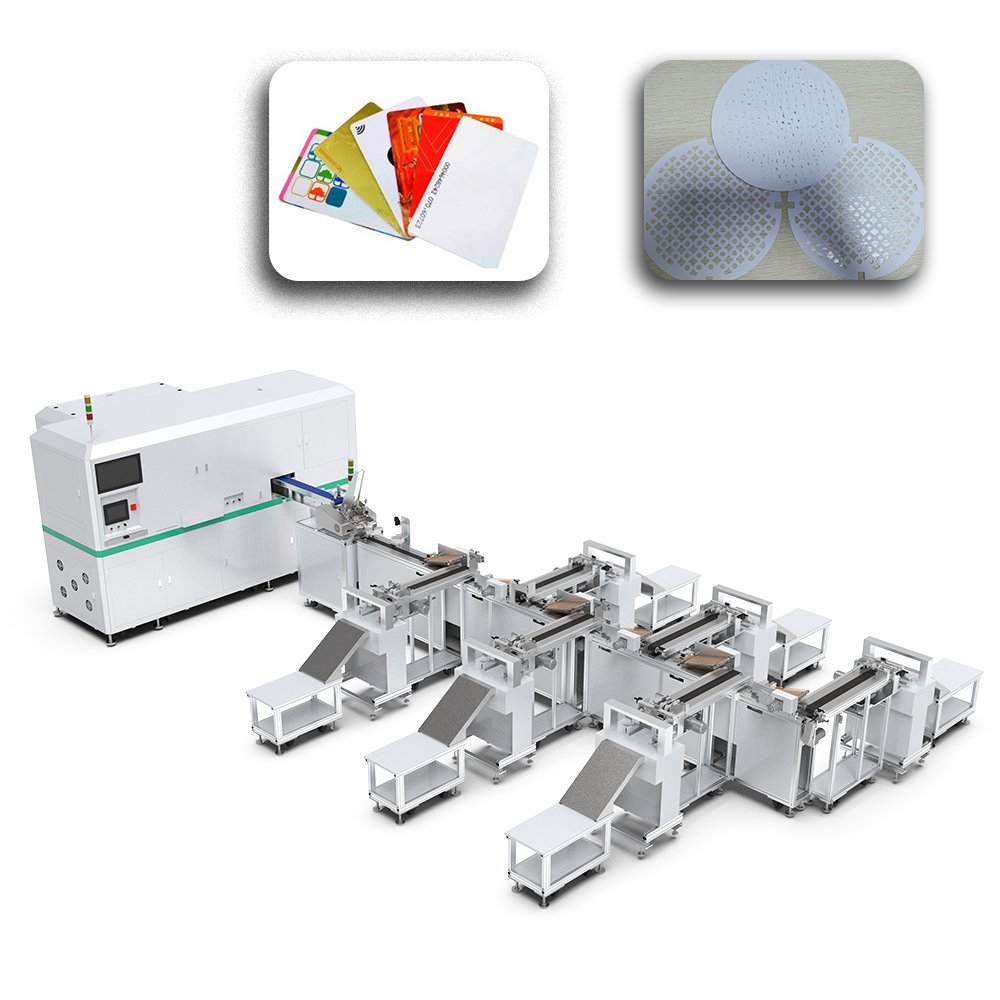

3. Automatic sorting system for game card punching and cutting machine

The game card punching machine is equipped with an intelligent identification system, which can automatically classify and finally sort the parts after cutting and punching. This function can also be selected according to customer needs:

Collect in sequence: Maintain the continuity of the production process.

Collected by category: convenient for subsequent processing and packaging

This feature improves production efficiency. At the same time, it also minimizes the cost and error margin of manual sorting.

4. Efficient power system

The 7.5 kW servo drive system ensures stable and powerful output. The servo system not only ensures the stable operation of the system but also reduces the energy consumption of the system. The servo system is characterized by fast response and accurate positioning, which makes it very suitable for long-term continuous work.

5. Optional hot stamping process

The game card punching machine can be equipped with hot stamping, and the surface decoration treatment can be carried out after die cutting. This is ideal for the production of high-end cards, as it adds value to the product. It also saves time, as it allows multiple processes to be completed in one pass.

Detailed explanation of the advantages of the game card punching and cutting machine

Excellent durability

High-strength steel and wear-resistant materials make the service life of the whole machine longer. Key components are also able to withstand long periods of heavy-duty use, so they must be heat-treated to maintain stable performance. The mechanical structure of the design also minimizes the chance of equipment failure.

Flexible customization options

We provide one-stop customized services, including:

Customized mold: Design a special mold according to the customer’s requirements.

Collection method customization: flexible configuration of finished product collection system

Capacity customization: Optimize equipment parameters according to production demand.

This customized solution ensures that the individual production process requirements of each customer can be seamlessly met.

Mature technology guarantee

The control system of the game card punching and cutting machine draws on many years of on-site experience, relies on accumulated technology, and has been optimized and upgraded many times. The system interface is friendly. Even if the operator has not received professional training, he can master the use method of the equipment after simple training.

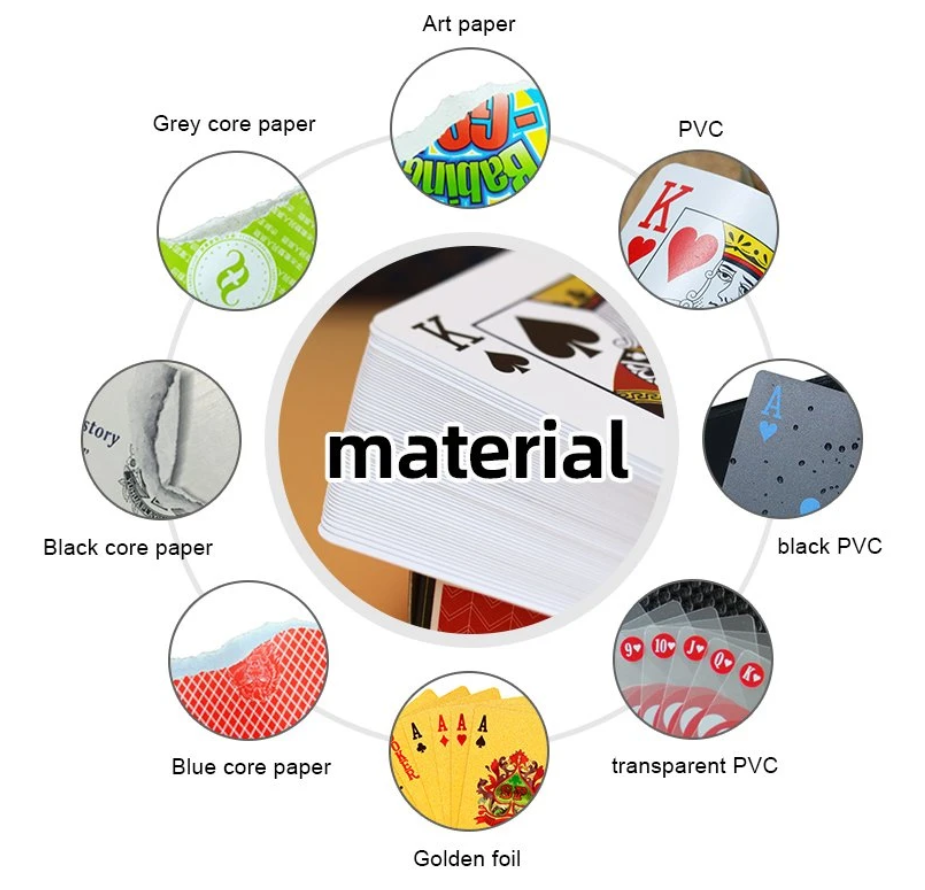

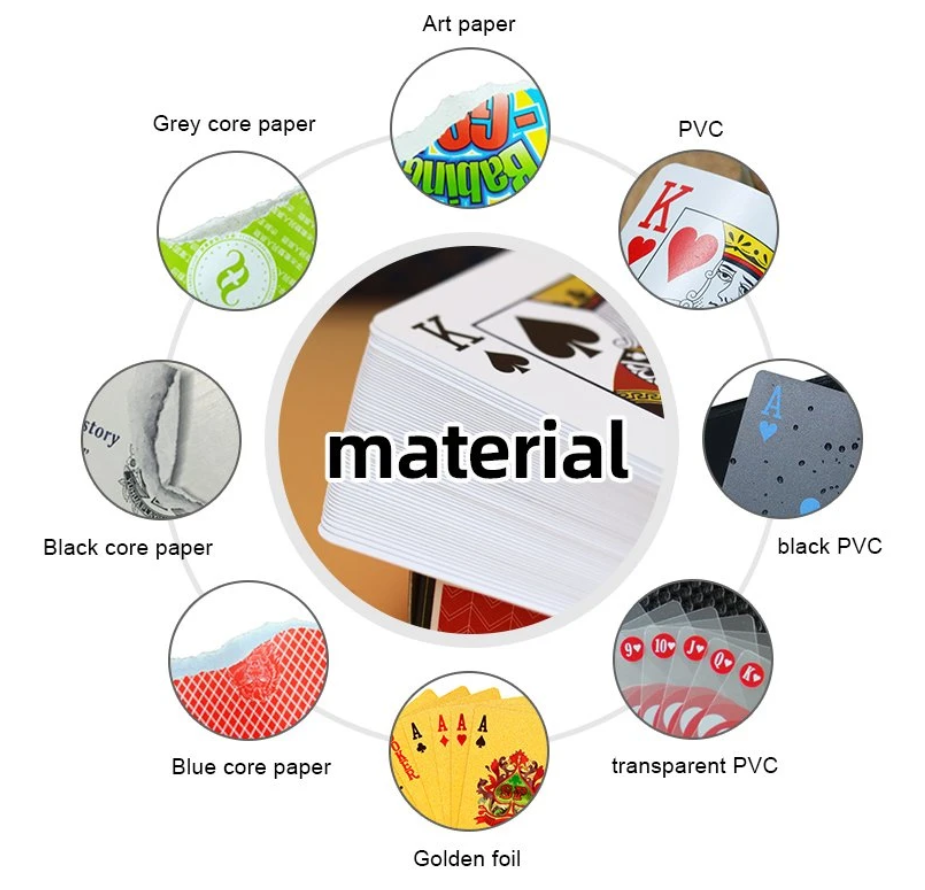

Unique texture presentation

The game card punching machine excels in the textile properties of various materials through precise temperature and pressure control. Whether it is smooth and delicate card paper or evenly textured filter paper, the best results can be achieved.

Technical parameters of the game card punching machine

Rated power: 7.5 KW

Punching accuracy: ±0.1 mm

Production speed: adjustable, up to 6000 times/hour

Applicable material thickness: 0.1-3.0 mm

Equipment size: customized according to configuration

Control system: PLC intelligent control

Application field of game card punching machine

This equipment is widely used in:

Card manufacturing industry: game card production, membership card production, smart card processing

Filter paper production industry: industrial filter paper, food-grade filter paper, special filter paper

Printing and packaging industry: calendars, notebooks, brochures

Office supplies industry: file bags, envelopes, etc. WENTONG Machinery Quality Assurance

Wintone provides perfect technical and after-sales service support for each device.

Installation and debugging: Professional engineers install and debug on-site.

Operation training: complete operation and maintenance training

After-sales support: 24-hour technical consultation, rapid response

Spare parts supply: Original spare parts are guaranteed and supplied in a timely manner.

Conclusion

The game card punching machine is flexible in application and unparalleled in performance. It is the preferred equipment for card production and filter paper processing. Whether you are building a new production line or a production base, we can solve your production needs efficiently and effectively. Contact us for more information and customized solutions. We will meet and exceed your production needs with the best technical support you can get.