Industry pain points

As a leisure product, the puzzle’s exquisite design, which carries cultural and creative value, makes it necessary to solve some specific and unique technical problems in the production process. However, some common puzzle production equipment cannot meet the following basic production needs.

The stamping accuracy is as high as possible so that each piece of the puzzle can be seamlessly engaged.

The edges must be smooth and free of burrs to enhance the user experience.

Adapt and adjust to different levels of design complexity, from children’s puzzles to complex adult puzzles.

The production materials can be diversified, and the base materials, such as paper, wood, and plastic, can be used.

Equipment positioning of jigsaw card punching machine

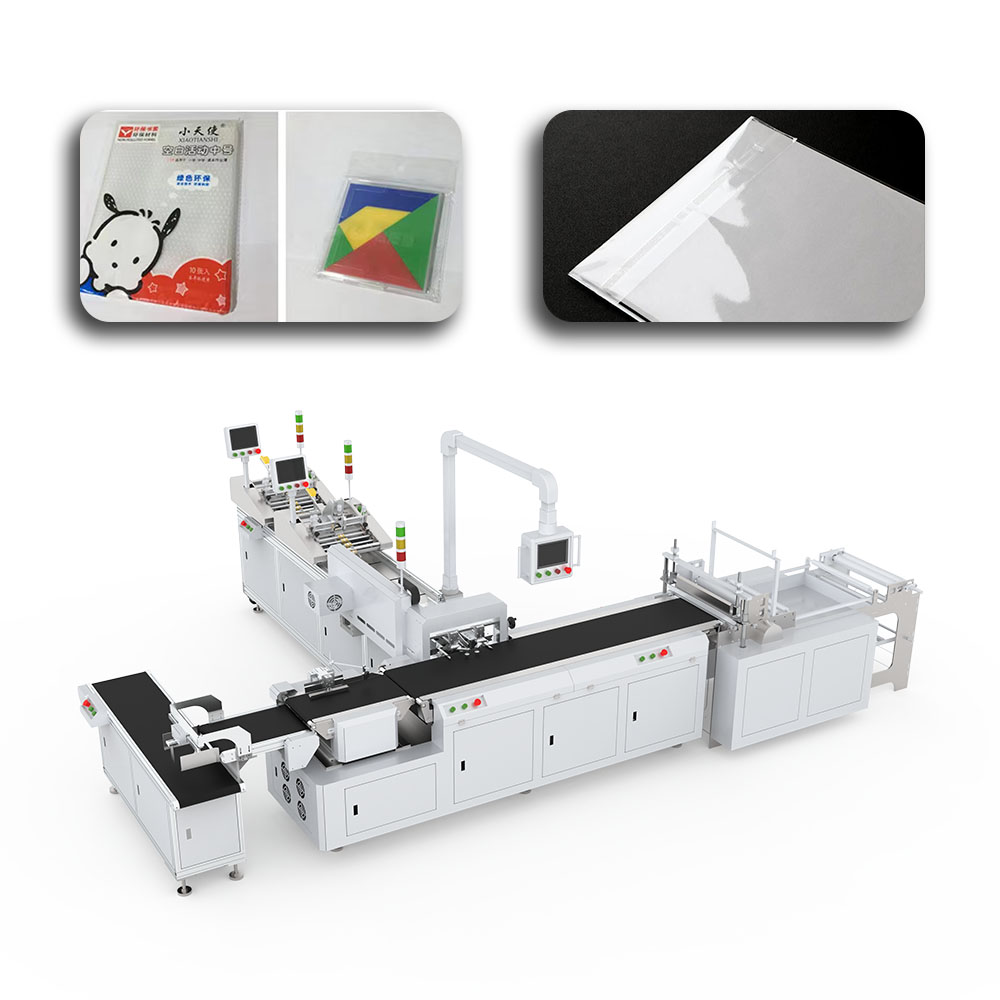

The puzzle card punching machine, which can punch, sort, and collect in one, provides a complete production solution for puzzle production enterprises and represents the high-end equipment in the puzzle manufacturing industry.

Core technology advantages of punching machine

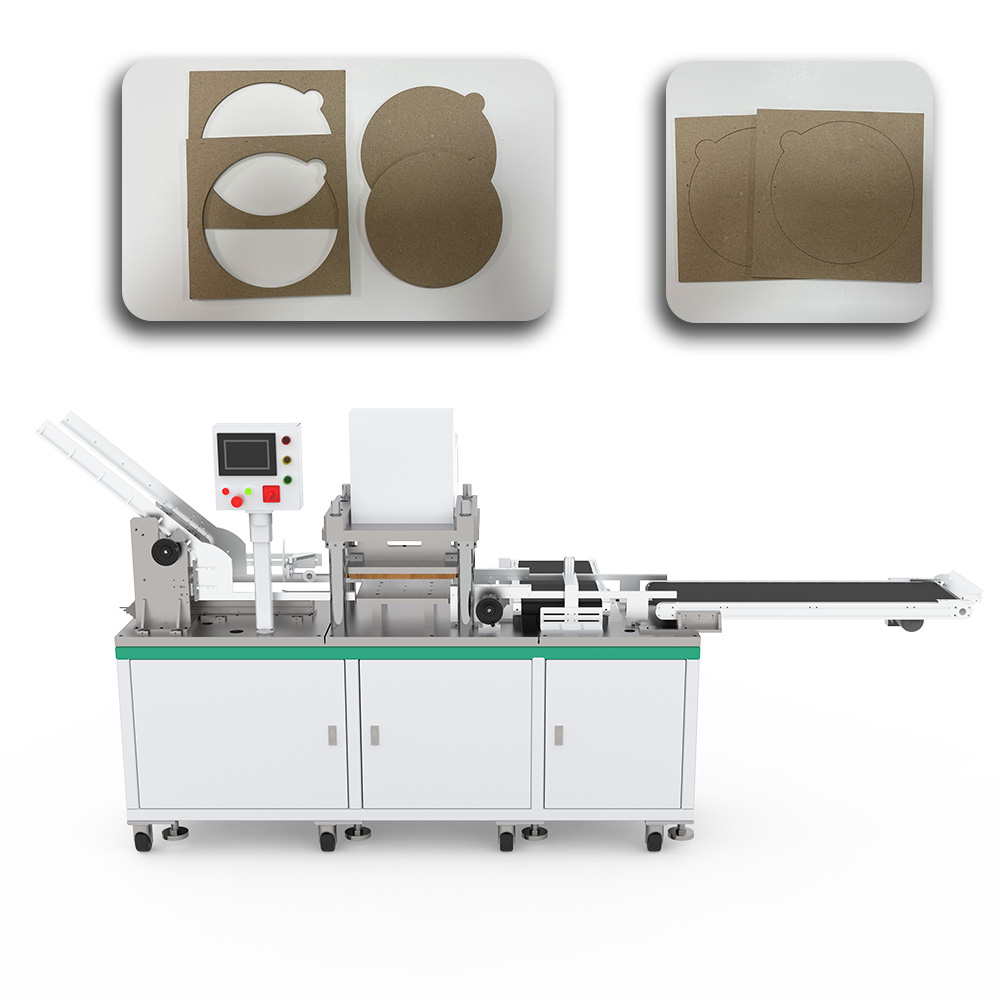

1. Precision die-cutting system designed specifically for jigsaw puzzles

Our punch presses achieve unparalleled precision and control thanks to proprietary die designs and state-of-the-art pressure control, resulting in puzzle seams that align perfectly. Unlike traditional equipment, our equipment can achieve:

The puzzle bite accuracy is ±0.1 mm, and the puzzle pieces are perfectly integrated.

20-2000 pieces of puzzle design, with different difficulty puzzle selections.

Special blade treatment technology eliminates burrs and smooths edges.

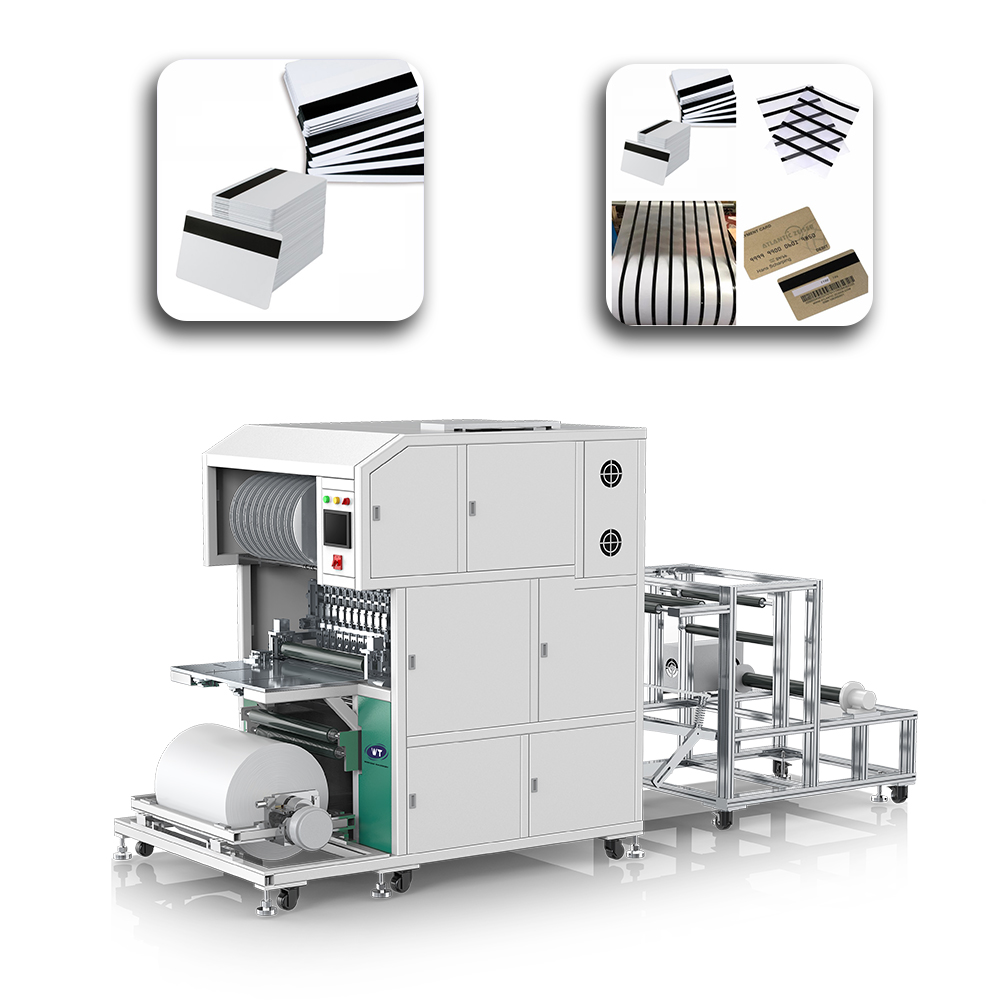

2. Adaptability to various puzzle materials

Paper jigsaw puzzle: gray board, white cardboard, and other special paper.

Wooden jigsaw puzzle: Support precision stamping of 3-5 mm thick wooden boards.

Plastic jigsaw puzzle: The processing of plastic materials such as PVC and ABS is also applicable.

Special materials: Other special categories include glow-in-the-dark puzzles and magnetic puzzles.

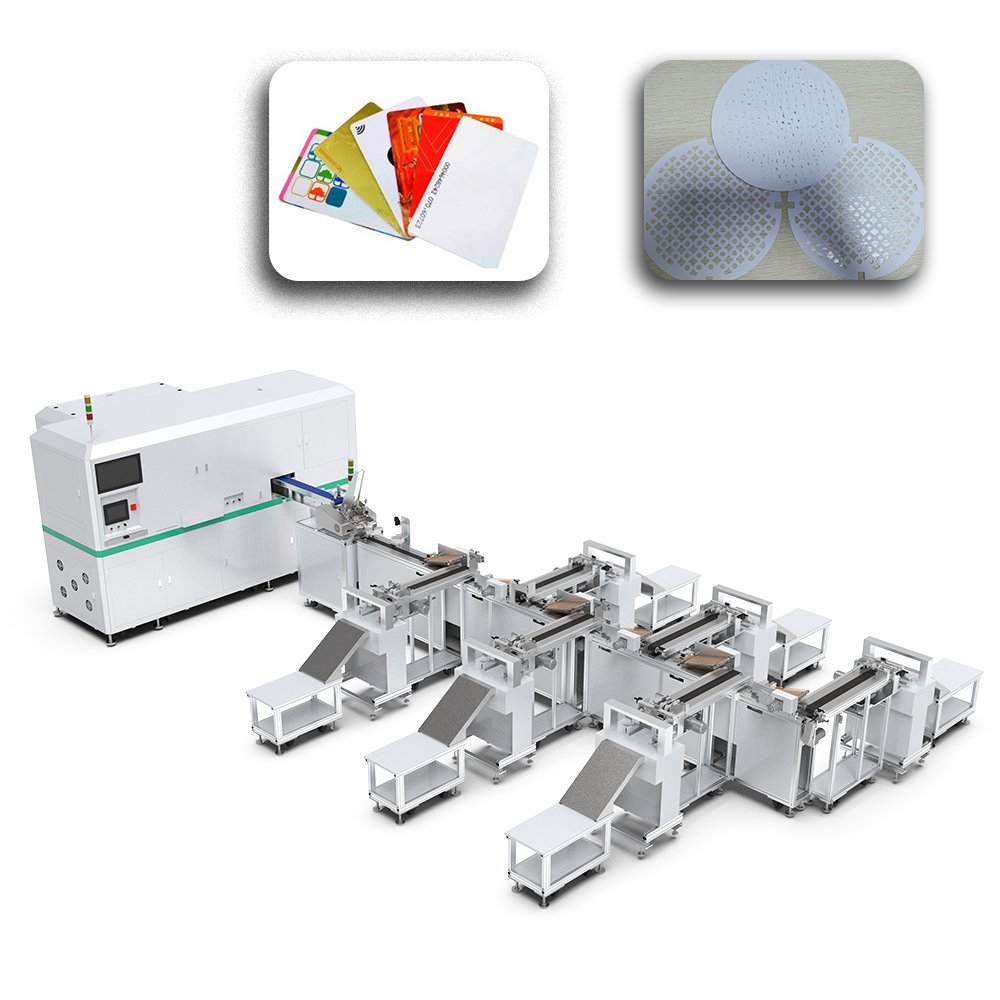

3. The automation revolution in jigsaw puzzle production

Puzzle production automation revolution The automation system of integrated equipment has brought a revolution to puzzle production:

Puzzle sorting and classifying automation system by region.

The intelligent system detects, evaluates, and automatically collects the jigsaw puzzles after stamping.

The 7.5 kW servo system provides stable power and breaks the consistency of mass production.

4. The infinite possibilities of puzzle customization

In response to the personalized needs of the industry, the equipment provides customized support:

Quick and easy mold replacement, easily coping with the switching needs of different puzzle patterns.

Support exclusive custom puzzle production.

Optional hot stamping, UV, and other additional units can be selected to realize various surface treatment processes.

5. Production process optimization

The production process of a jigsaw puzzle: design → printing → die cutting → sorting → packaging (many links, scattered equipment).

6. Optimized process for using jigsaw card punching machine:

The jigsaw puzzle card punching and cutting machine simplifies the process: design → printing → integrated punching and cutting sorting → packaging (integrated production). Puzzle manufacturers can save more than 30% of equipment costs. Production efficiency increased by 40%. The error rate of manual sorting has been reduced to less than 1%.

Application case of puzzle card punching machine

Case 1

One customer has achieved automated punching, sorting, and collection with three machines:

Now, the staff only needs two people.

Daily output increased from 5,000 boxes to 8,000 boxes.

The product defect rate has been reduced from 3% to 0.5%.

Case 2

The client is a manufacturer of children’s educational puzzles, and the safety standards are very strict:

The edges must be completely free of burrs.

Automatic sorting helps prevent contamination from manual contact.

A bespoke collection system is tailored to each individual order, maintaining the integrity of the optical jigsaw.

Quality Assurance System

The multiple inspection system of the

jigsaw card punching machine ensures the quality of various jigsaw components:

The stamping quality is continuously monitored.

An automatic dimension detection system is adopted.

Check and verify the smoothness of the edges.

The cutting and punching quality of the jigsaw puzzle is evaluated by the bite test.

Jigsaw card punching machine technical service support

Provide comprehensive puzzle design and production support for puzzle manufacturers:

Suggestions for optimizing the production process.

Production process optimization suggestions

Train personnel who will operate the equipment.

24-hour remote technical support

Market Competitiveness Analysis of Puzzle Card Punching Machine

Compared with traditional jigsaw puzzle production equipment, the jigsaw puzzle card punching machine has obvious advantages in the following aspects:

Accuracy comparison

Traditional equipment: ±0.3 mm

This equipment: ±0.1 mm

production efficiency

Traditional equipment: 3,000-4,000 boxes/day

This equipment: 6000-8000 boxes/day

Degree of automation

Traditional equipment: requires multiple devices to work together

This equipment is an integrated automatic production solution.

Conclusion

The introduction of the

jigsaw card punching machine has changed the technical standards of jigsaw production. The equipment solved the accuracy and speed problems of jigsaw puzzle production for the first time and provided the potential for future production for jigsaw puzzle production enterprises. The equipment excels at producing traditional paper puzzles as well as modern wooden and plastic puzzles.

As a pioneering equipment manufacturer in the jigsaw puzzle manufacturing industry, we prioritize and invest in technological advancement to help jigsaw puzzle production companies around the world improve their competitiveness and produce more exquisite jigsaw puzzles.