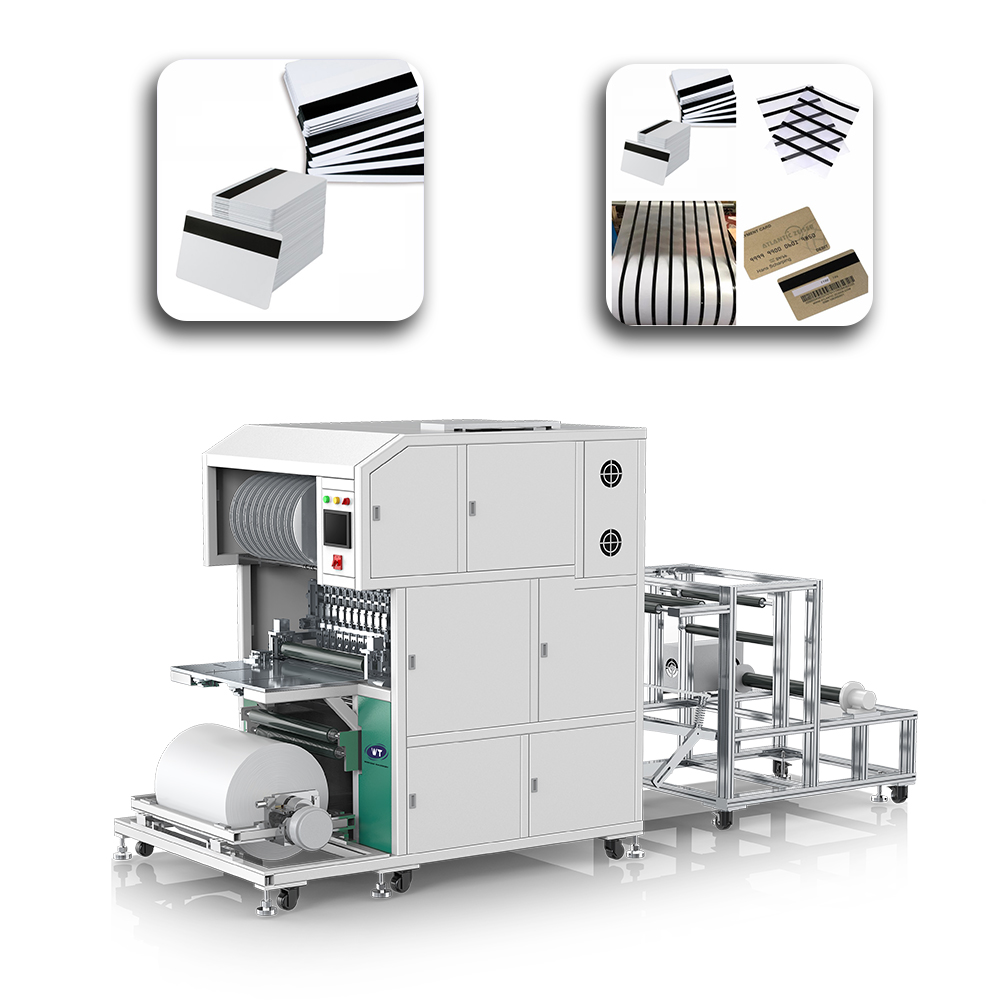

1. Product Overview

The

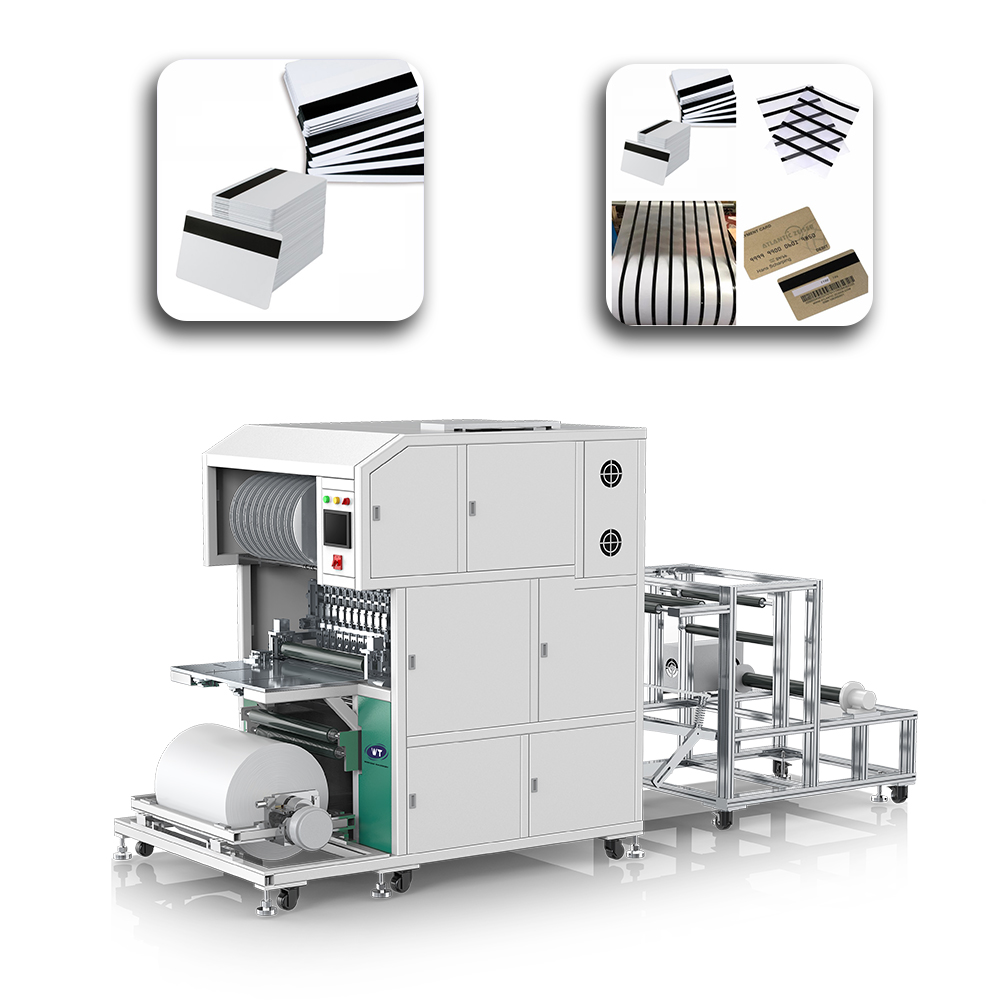

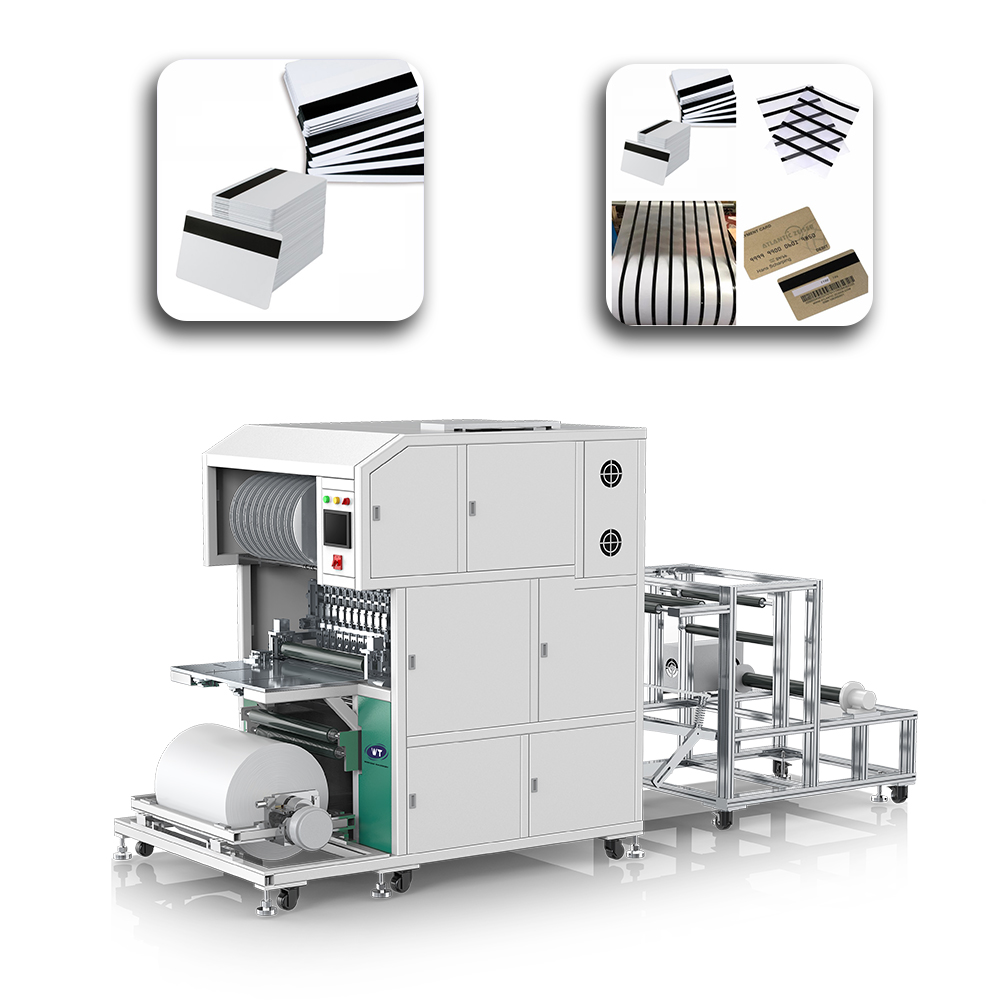

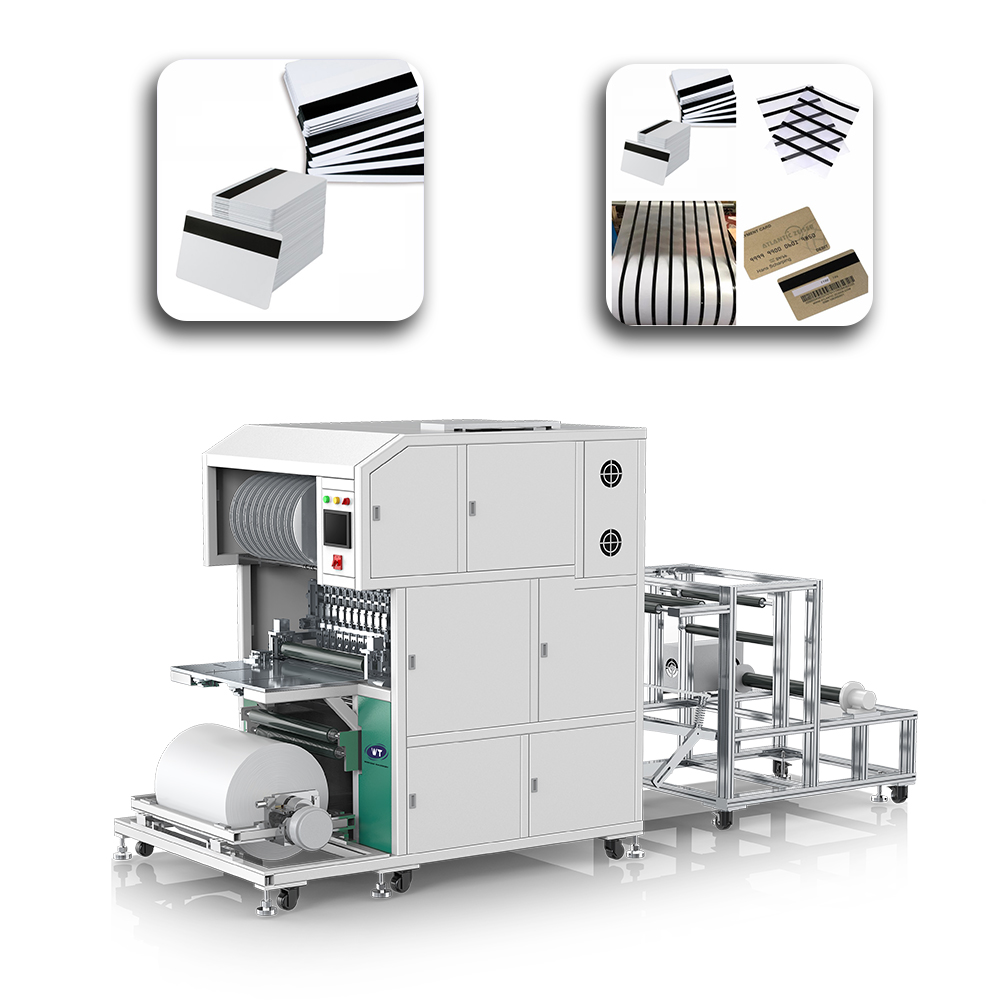

film magnetic stripe machine is a fully automatic piece of equipment used to accurately weld magnetic stripes on PET, PVC, and paper cards. The equipment integrates the functions of feeding, welding, and cutting and masters the automation of magnetic stripe processing. Automation is of great benefit to the continuity of enterprises and magnetic stripe products. The machine has the characteristics of precise temperature control and stable welding, and it also saves the tedious manual operation. The equipment is widely used in card making, packaging, printing, and other industries. These industries have also enjoyed the benefits of automation.

The

film magnetic stripe machine has also gone global, a representative work of Shenzhen equipment manufacturers. These machines also serve a growing customer base in Europe, the Americas, Southeast Asia, the Middle East, and other regions as reliable magnetic stripe processing solutions.

2. Design Concept and Technological Innovation

1. High-precision servo drive system

The machine adopts a servo motor to control the running speed, feeding speed, and feeding length without error. The sensors provide fast response and reliability during high-load operation, thus avoiding the traditional problems of mechanical and pneumatic systems.

2. Intelligent temperature control system

The heating tube technology is adopted, and the imported temperature probe and temperature control module are used to make the welding temperature accurate. This ensures that the magnetic strip is fused with the material without bubbles or warping. For the user, the temperature parameters are very easy to set on the user-friendly interface. The system maintains the set temperature, which is suitable for welding different materials.

3. Independent adjustment function

The temperature and pressure of each magnetic head are independent, which means that different material thicknesses and different materials (such as PET, PVC, and paper cards) can be flexibly adjusted. This greatly improves the production flexibility and adaptability of the equipment.

4. Welding and cutting are completed simultaneously.

The magnetic stripe machine is also cutting when the magnetic stripe is welded. The cutting length is very accurate, ensuring that the product has no burrs or defective products. Therefore, there is no need for post-operation, which improves production efficiency.

5. Wide compatibility

The application field of the equipment is very wide, and it can produce different product thicknesses, from PET to paper cards.

3. Detailed explanation of core functions

1. Automatic feeding system

Precise feeding: The servo motor is used for precise feeding, and the magnetic strip and material are precisely moved according to the set length and speed.

Adjustable parameters: Users can set different feeding lengths and speeds according to their production needs.

2. Welding system

Temperature control: PID control temperature technology effectively controls the welding temperature within the range of ±1℃, providing good welding consistency and high stability.

Pressure adjustment: Each magnetic head has independent pressure control to prevent uneven welding due to uneven material thickness and ensure welding effect.

3. Cutting system

Precision cutting: The equipment uses high-precision guide rails and CNC to ensure the high precision of the magnetic strip, and the error is less than 0.0 mm.

No burr design: The blade is made of special steel, and after heat treatment and a special process, it can ensure that the cut is free of wedge shape and smooth.

4. Human-computer interaction interface

Intuitive operation: The system is centrally operated with one key, and the machine running parameters are displayed: running status, temperature, and feeding parameters.

Self-diagnosis of faults: The system automatically monitors and reports faults, minimizing the machine repair time.

4. Application Scenarios and Industry Value

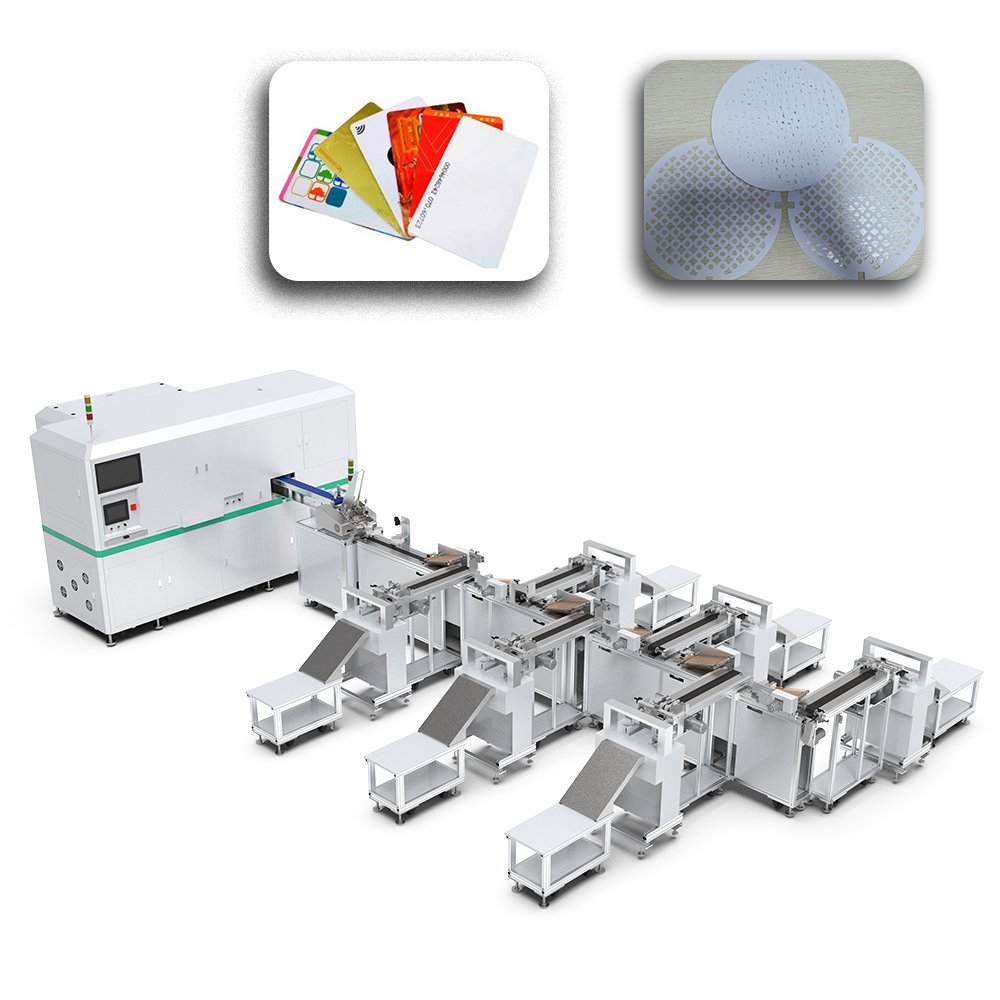

1. Card Manufacturing

Application cases: membership cards, access cards, gift cards, etc.

Value embodiment: The high-precision welding process is adopted to combine the magnetic stripe and the card so that the magnetic stripe on the card will not fall off.

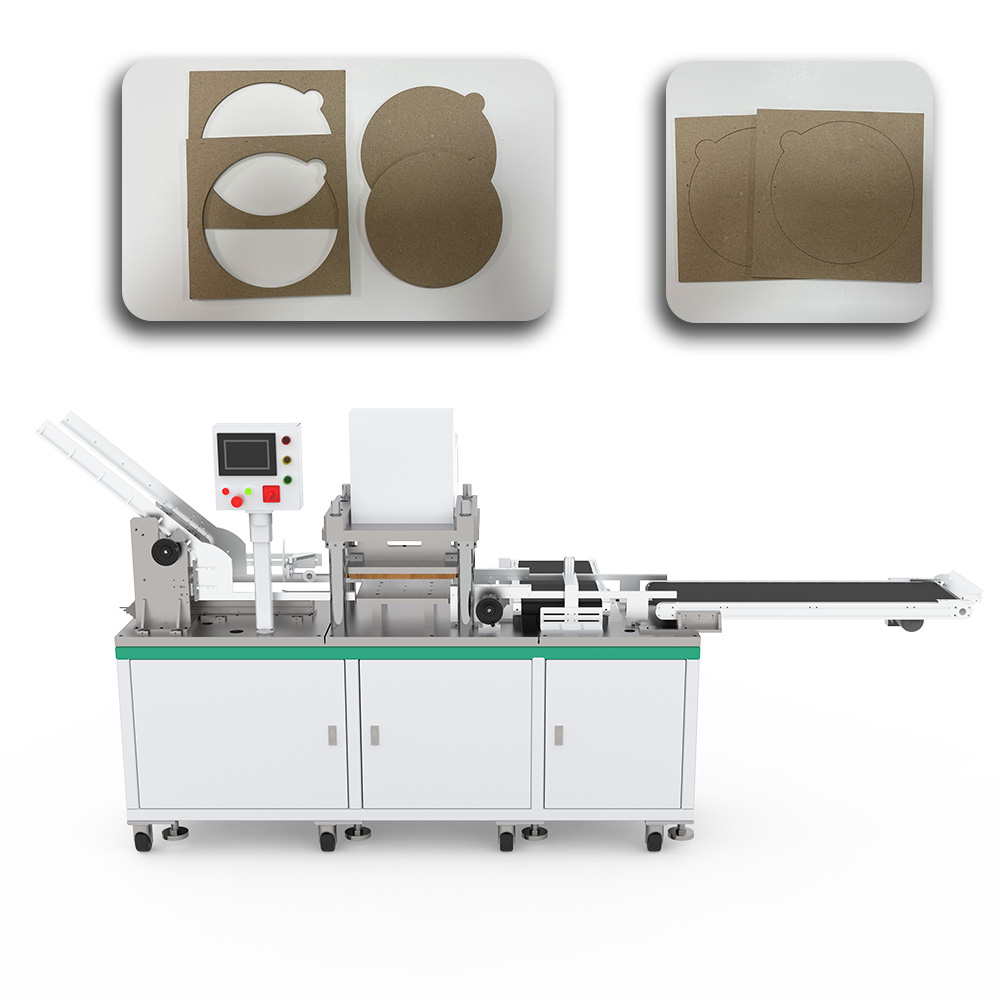

2. Packaging industry

Application cases: magnetic packaging boxes, display racks, gift boxes, etc.

Value embodiment: The automatic welding and cutting of packaging products greatly improves the consistency and production efficiency.

5. Technical parameters

| Power supply |

AC 380V/50 HZ |

Format |

3X8/4X8/5X5/5×6/8×8 optional |

| Total power |

2.5KW |

Control |

PLC control + servo system |

| Air source |

6 kg/cm2 |

Operators needed |

1 |

| Air consumption |

Approx. 80L/min |

Dimension |

L2250*W1000*H1700MM |

| Laying accuracy |

±0.15mm |

Product thickness |

0.2mm~1.0mm |

| Temperature control accuracy |

±2℃ |

Temperature control range |

0~400℃ |

| Magnetic tape width |

6.35mm/8.4mm/12.7mm |

Quantity of magnetic tapes |

5~12 |

| Applicable materials |

Paper card, PVC, ABS, PET, PVC/ABS composite materials, etc. |

Productivity |

900 Sheet/H |

6. Service and Support

Global Sales Network

The equipment is designed to support a multi-language operation interface and international electrical standards. Therefore, the products are sold to Europe, America, Southeast Asia, the Middle East, and other regions.

Customized service

The equipment parameters and functions can be customized to provide personalized services.

After-sales service

Provide installation, operation training, equipment debugging, technical support, and other services around the world to ensure the normal operation of equipment, serving more than 40 countries.

7. Conclusion

The

magnetic stripe machine has a high degree of automation. The welding effect is stable, and the process control is advanced. Provide reliable and efficient magnetic strip welding and cutting solutions for enterprises. The equipment can improve product quality or improve production efficiency, and the effect is remarkable. Technical integration and global service delivery enable us to ensure that our global customers continue to experience value and innovation. We are proud to be located in Shenzhen, one of the most technologically innovative cities in the region, as the value-added services we provide to our global customers help us innovate at the forefront of global technology.