Magnetic product manufacturers, such as refrigerator magnets, magnetic price tags, and POP advertising boards, have slow speeds and difficulty in ensuring accuracy due to traditional manual or semi-automatic punching methods. It also cannot meet the market’s demand for rapid response to personalized and small-batch orders. It is in this context that the

magnetic die-cutting machine came into being and became the main force to change the industry.

This article will analyze in depth how modern

magnetic die-cutting machines provide complete production solutions for the global advertising, retail, automotive, and gift industries with their excellent performance and automatic sorting functions. We are based in Shenzhen, China, at the forefront of global manufacturing and technological innovation. We are committed to promoting this high-performance equipment to the global overseas market to help customers become more competitive.

1. Understanding the magnetic die-cutting machine: more than just die-cutting, it is also an intelligent production unit.

1. Understanding the magnetic die-cutting machine: more than just die-cutting, it is also an intelligent production unit.

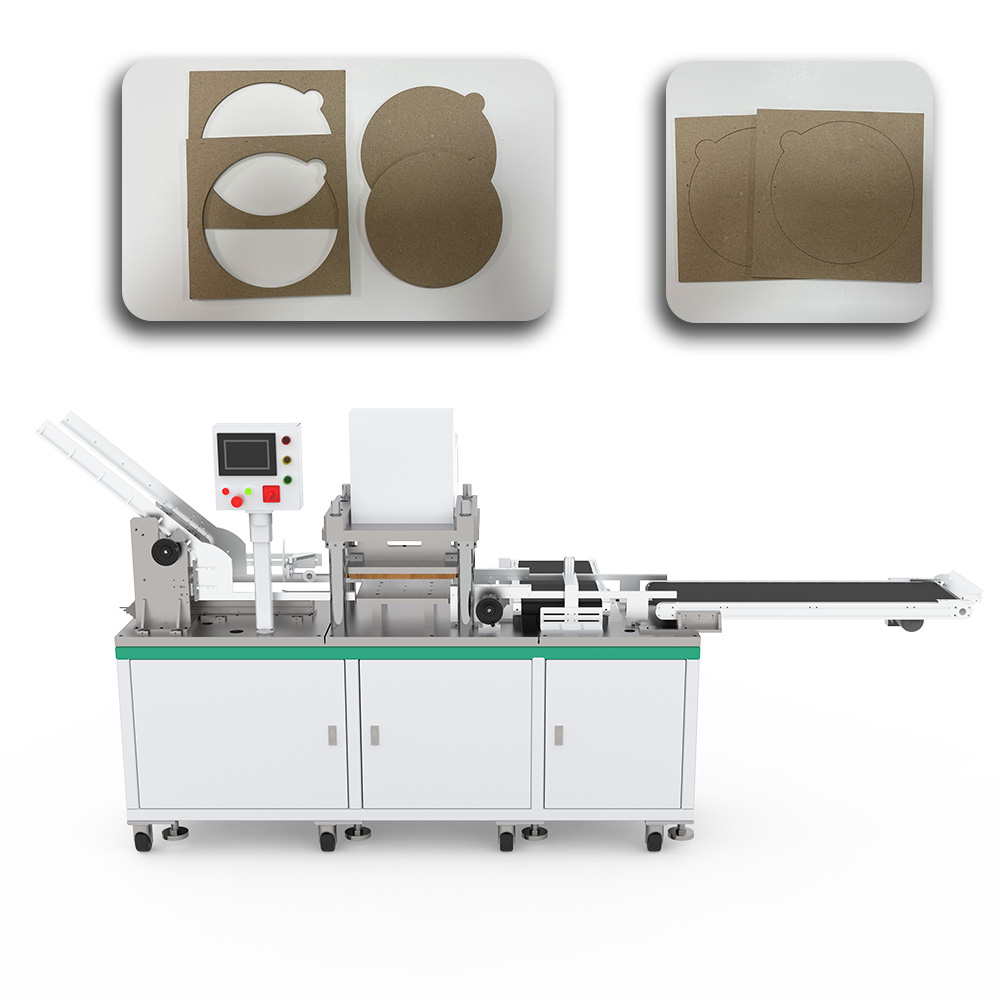

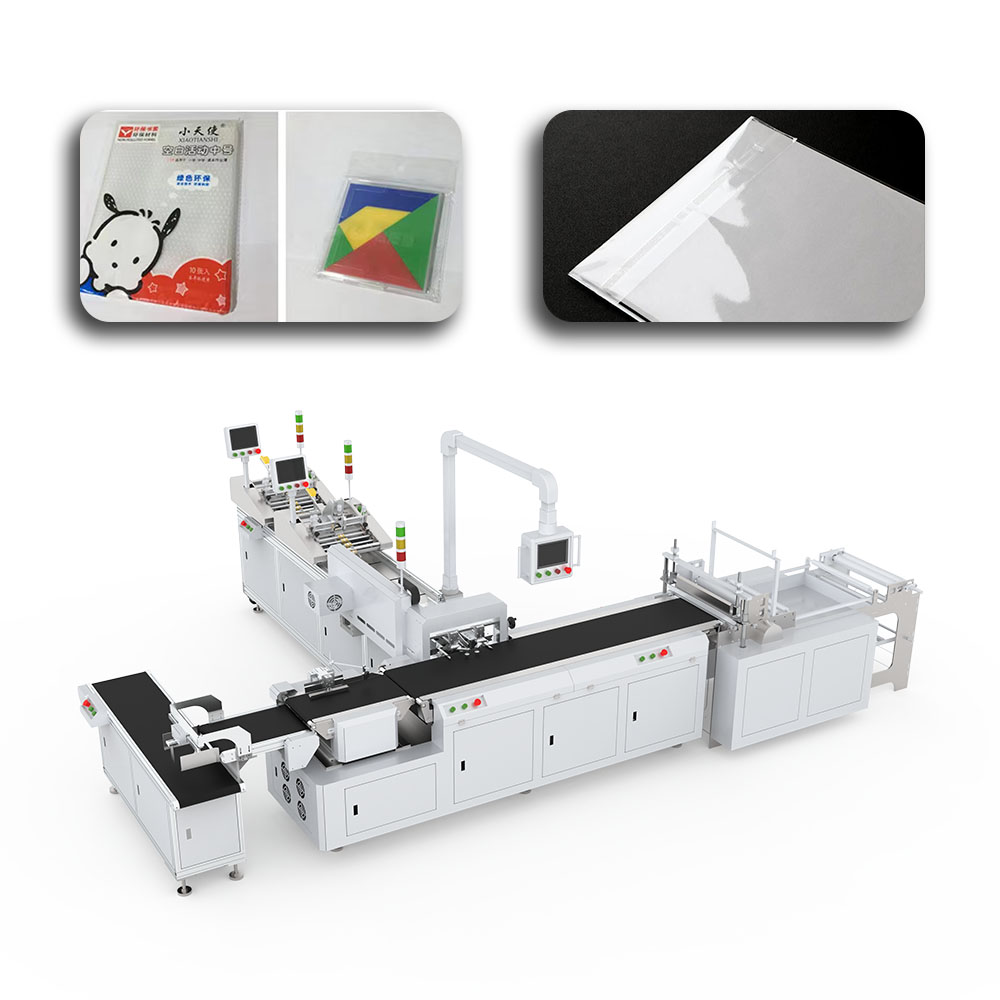

The automatic magnetic die-cutting machine is very precise equipment, which is specially used for the processing of magnetic materials, such as magnetic PVC, magnetic rubber, soft magnetic, etc. Its main function is to use the servo drive system to maintain stable pressure and to punch the material into finished products of different shapes through customized molds, such as exquisite logo refrigerator stickers, durable magnetic car stickers, standardized magnetic price tags in shopping malls, and various magnetic POP billboards.

But modern

magnetic die-cutting machines have long since gone beyond the concept of “punching.” By adding modules such as automatic sorting, material collection, and stacking, it becomes an intelligent micro-production unit. From the roll or sheet material on the machine to the final product, the sorting is carried out in order or category, and the whole process does not require a lot of manual input. This makes the production operation efficient and continuous.

2. The top ten core advantages of the magnetic die-cutting machine accurately solve the pain points of production.

Our magnetic die-cutting machine has been tested by the market and has many years of technical precipitation. We have summarized ten advantages, which directly hit the pain points of the traditional production mode.

1. Unique texture: gives the product excellent visual and tactile sensation

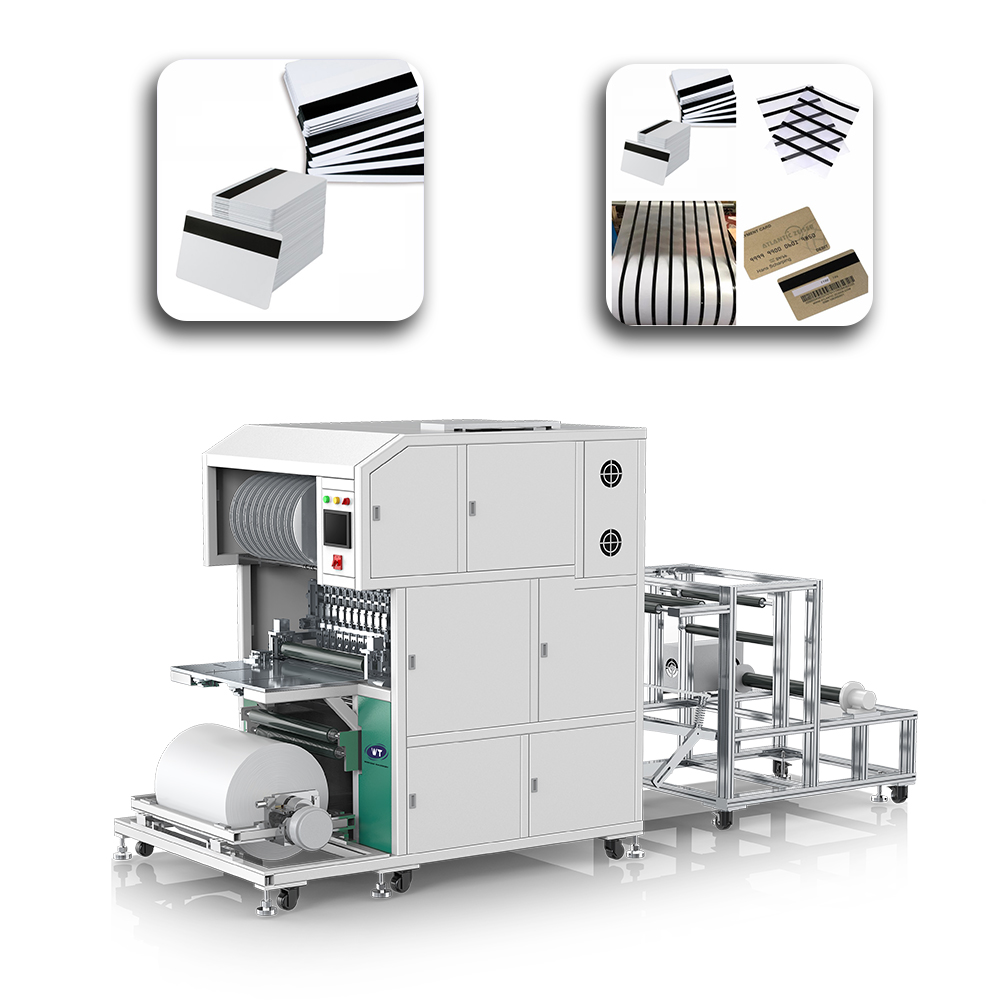

The equipment adopts a high-rigidity frame and precision guiding structure to ensure uniform and stable pressure during stamping. The punched products have no burrs on the edges and the cross section is flat and smooth. It can add high-end and unique texture to the magnetic stripe membership card with a soft hand feeling or the logo refrigerator magnet with a fine pattern and directly improve the brand image.

2. Excellent durability: ensures long-term stable operation of the equipment

The whole machine adopts high-quality steel and wear-resistant parts. The key structure is optimized by finite element analysis, and the fatigue resistance is good. This means that the equipment can handle high-intensity production tasks around the clock, providing a reliable production guarantee for enterprises and reducing downtime and maintenance costs caused by equipment failure.

3. Multi-application of equipment: one machine for multiple purposes, maximizing the return on investment

One machine for multiple purposes: one machine can do multiple jobs, maximizing your investment.

This magnetic die-cutting machine has excellent adaptability. By changing the mold and adjusting the settings, it can perfectly handle various magnetic materials. It can also be used for other purposes, such as die-cutting of non-magnetic materials such as books and filter paper. This “one machine, multiple uses” feature greatly expands the company’s business scope, maximizes the return on investment in equipment, and is especially suitable for processing enterprises that undertake diversified orders.

This magnetic die-cutting machine can be used in many different ways. By changing the die and settings, it can perfectly handle all kinds of magnetic materials. It can also be used for other purposes, such as cutting non-magnetic materials like books and filter paper. This “one machine for multiple uses” feature greatly expands the company’s business scope, maximizes the benefits of equipment investment, and is especially suitable for processing enterprises that undertake multiple orders.

4. With the hot stamping process: to achieve the integration of surface decoration

You can easily add a hot stamping module to the equipment to perform surface hot stamping while die-cutting. One-time molding improves the appearance of magnetic stripe points cards and promotional signs. This saves time and processes and avoids the waste that can occur with multiple alignments. It also perfectly combines decoration and function.

5. Mature technology: from practice, trustworthy

We have 20 years of industry experience and understand the needs of the industry very well. From mechanical transmission to electrical control, every part has been improved. The operation interface is user-friendly, and the fault self-diagnosis function is perfect. This makes the equipment stable and easy to use, and your production team can get started immediately.

6. Integrated customized overall solution: meet the needs of personalized production

We understand that every customer has different needs. Therefore, we offer both standard equipment and “one-stop customized overall solutions.” We can customize the mold and plan the process from the beginning to adapt to your products, such as custom-shaped magnetic car stickers or very small magnetic price tags. We can then add automated sorting and separation systems to ensure the equipment fits perfectly into your production line.

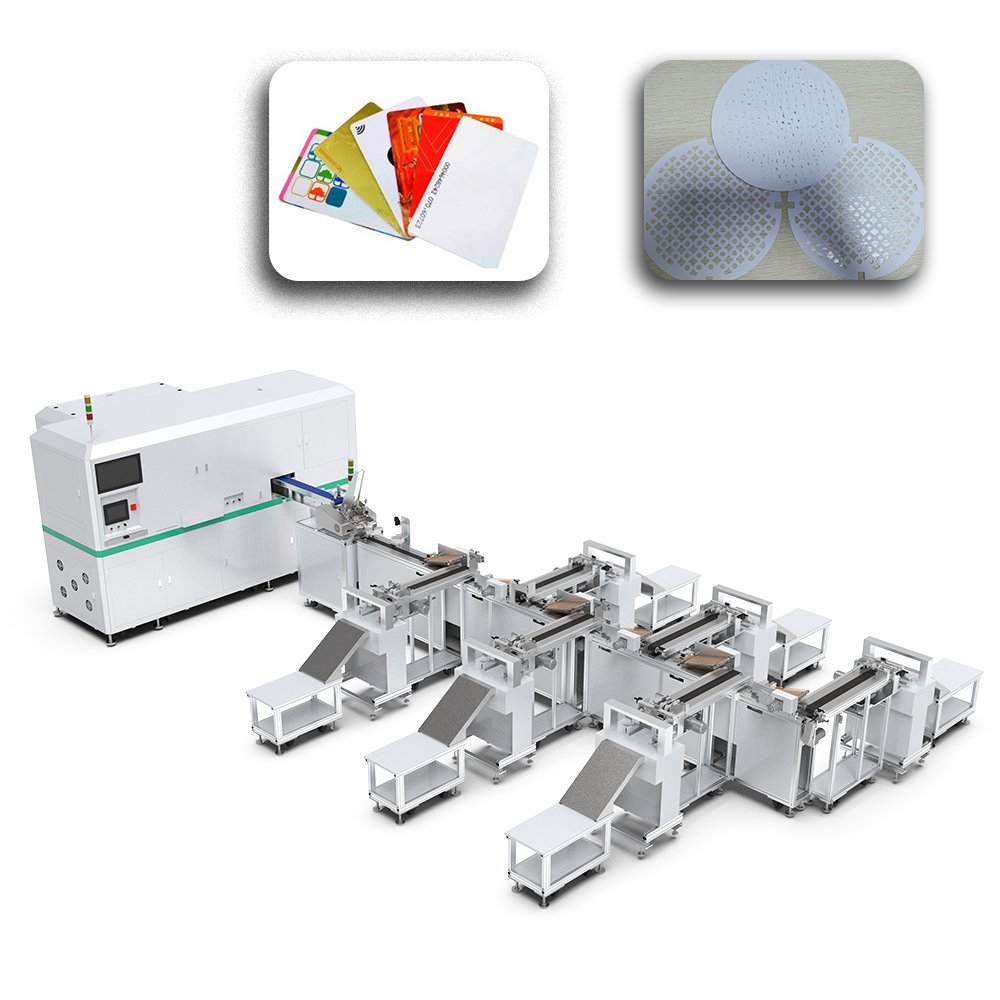

7. With automatic classification and sorting function: to achieve a leap in production intelligence

This is the main function of the equipment. The equipment can use the visual system or programming control to automatically sort and classify the finished products after die-cutting. The system can automatically identify different SKU refrigerator stickers after die-cutting on the same layout and put them into different material boxes. It completely solves the main problems of low efficiency and error-prone manual sorting.

8. Automation 7.5 KW servo drive: the source of power and precision

The main power source of the equipment is the 7.5 kW servo system of automation. The system has a fast response speed, high control precision, and low energy consumption. It provides stable and powerful stamping pressure, ensuring that even the most complex patterns can be perfectly made. At the same time, it can save more than 30% of energy compared with traditional hydraulic or ordinary motor drives. It meets the green and environmental protection standards of the modern manufacturing industry.

9. Customized collection method: making the back-end logistics better

We provide flexible finished product collection methods according to the production needs of users:

Sequential collection: suitable for making a large number of the same items at one time. The finished products are neatly stacked in the order of punching and cutting, which is convenient for packaging.

Collect by category: The automatic classification and sorting function classifies different types of goods (such as price tags of different models or promotional signs of different prices) and sends them directly to the warehouse management system. It makes the collaboration between production and logistics more convenient.

10. Accurate punching and cutting without burrs: the cornerstone of quality

The equipment has a high-precision servo system, a rigid body, and a high-quality mold, and the die-cutting precision is very high (the error is usually less than ±0.1 mm). The unique blade design and precise pressure control ensure that the product edges are smooth and burr-free, and no grinding is required. This directly improves the product yield and safety.

3. Customer groups of magnetic die-cutting machines

This strong magnetic die-cutting machine is mainly for the following people around the world:

In the advertising signage industry, they make magnetic car stickers, logo refrigerator stickers, and magnetic POP billboards. This is to provide customers with a wider range of high-quality advertising products.

Companies that help stores and supermarkets manage their supply chains: They make large quantities of identical magnetic price tags and promotional signs for stores and can easily track thousands of SKUs through automated sorting.

Printing and packaging enterprises: After the magnetic products are printed, they are also processed by die-cutting, hot stamping, etc., so that customers can get all the products in one place.

Gift and promotional item manufacturers, such as magnetic membership card and magnetic points card manufacturers. Because it can do so many things and can be changed according to market demand, it can quickly adapt to changes.

Why choose us? – Shenzhen Intelligent Manufacturing, Serving the World

We are a cutting-edge company based in Shenzhen, China, with unique advantages in supply chain and technology research and development. We are not just selling you equipment; we are your long-term partner. We offer a full range of assistance, from equipment installation and troubleshooting to training you on how to use the equipment and post-purchase maintenance. This way, you can be sure of receiving prompt and professional service whether you are in North America, Europe, or Southeast Asia.

Conclusion

In today’s era of manufacturing moving toward Industry 4.0, buying a high-performance, intelligent, multi-functional magnetic material die-cutting machine is definitely a wise move to seize the market opportunity. It can not only help you solve the problems of precision, efficiency, and flexibility encountered in the production of magnetic products, but also lead your enterprise into the world of intelligent manufacturing through automatic sorting, classification, integrated customized overall solutions, and other ways.

If you want a reliable machine that can increase productivity, reduce costs, and help your business grow, our magnetic die-cutting machine is your best choice. Contact us for more customized solutions and industry information.