This equipment is mainly used in food packaging, industrial filtration, and label printing. The label die-cutting machine is an important part of the production of cage paper for steamed buns and steamed buns that do not stick to the bottom, filter paper rings that improve the efficiency of liquid filtration, and wine label labels that enhance the brand image. However, traditional tools often have problems such as burrs in punching, low efficiency, single function, and inability to automatically sort.

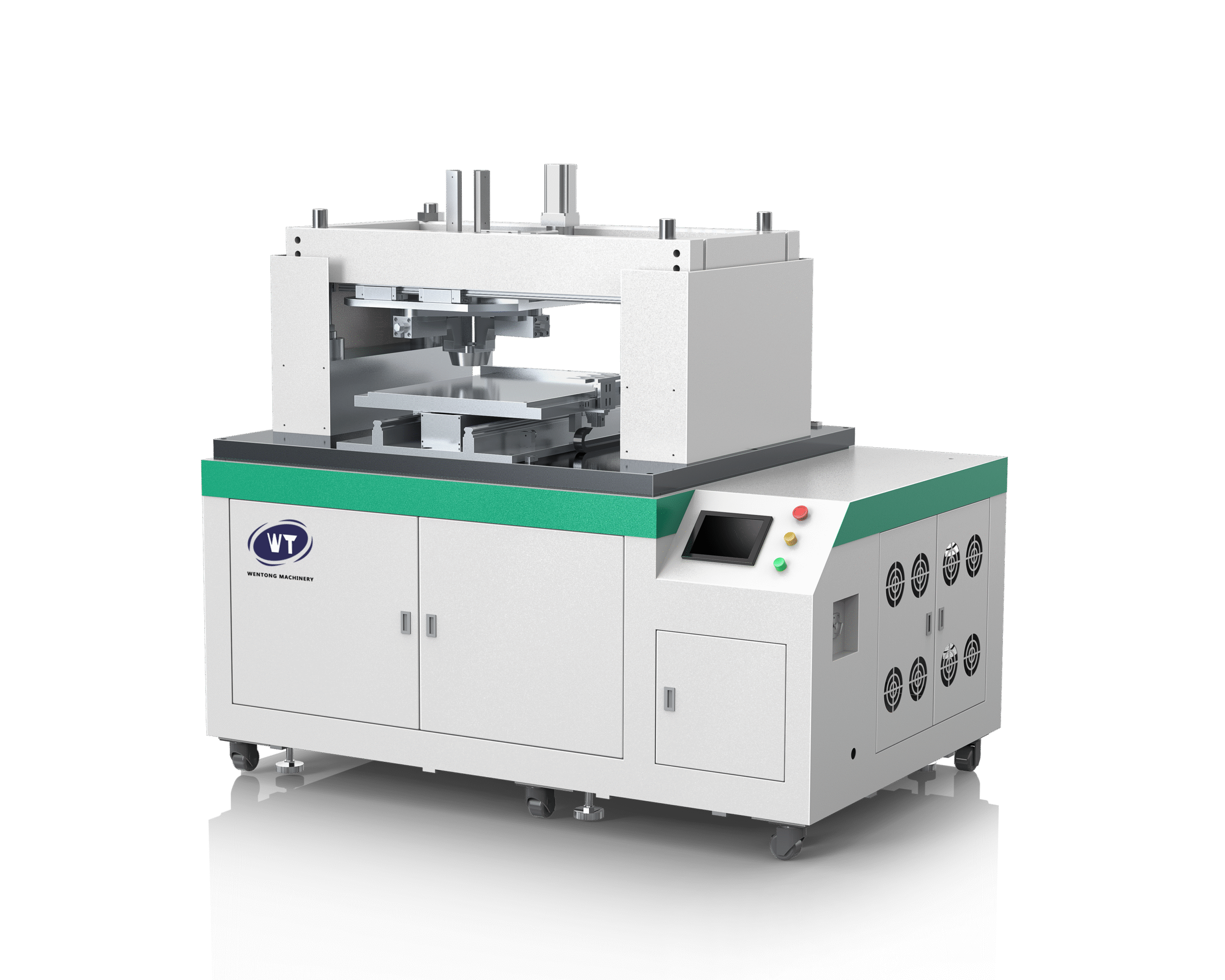

In order to solve these problems in the industry, our factory in Shenzhen, China, has created this high-performance filter paper die-cutting machine by using mature technical experience and understanding of the global market. It is not only a die-cutting machine but a complete solution including intelligent sorting, precise die-cutting, and efficient production. Committed to serving global overseas market customers, helping enterprises reduce costs, improve production efficiency, and make products more competitive.

1. The core production range of the filter paper die-cutting machine

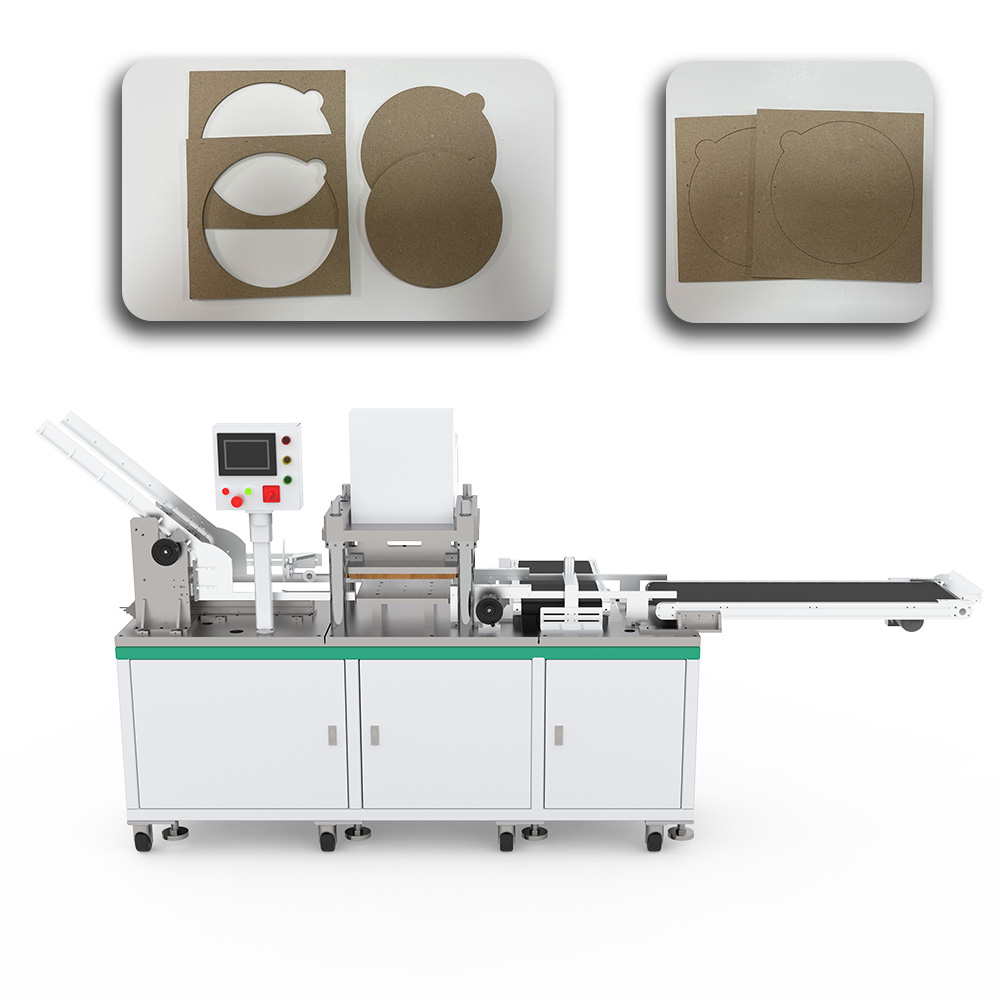

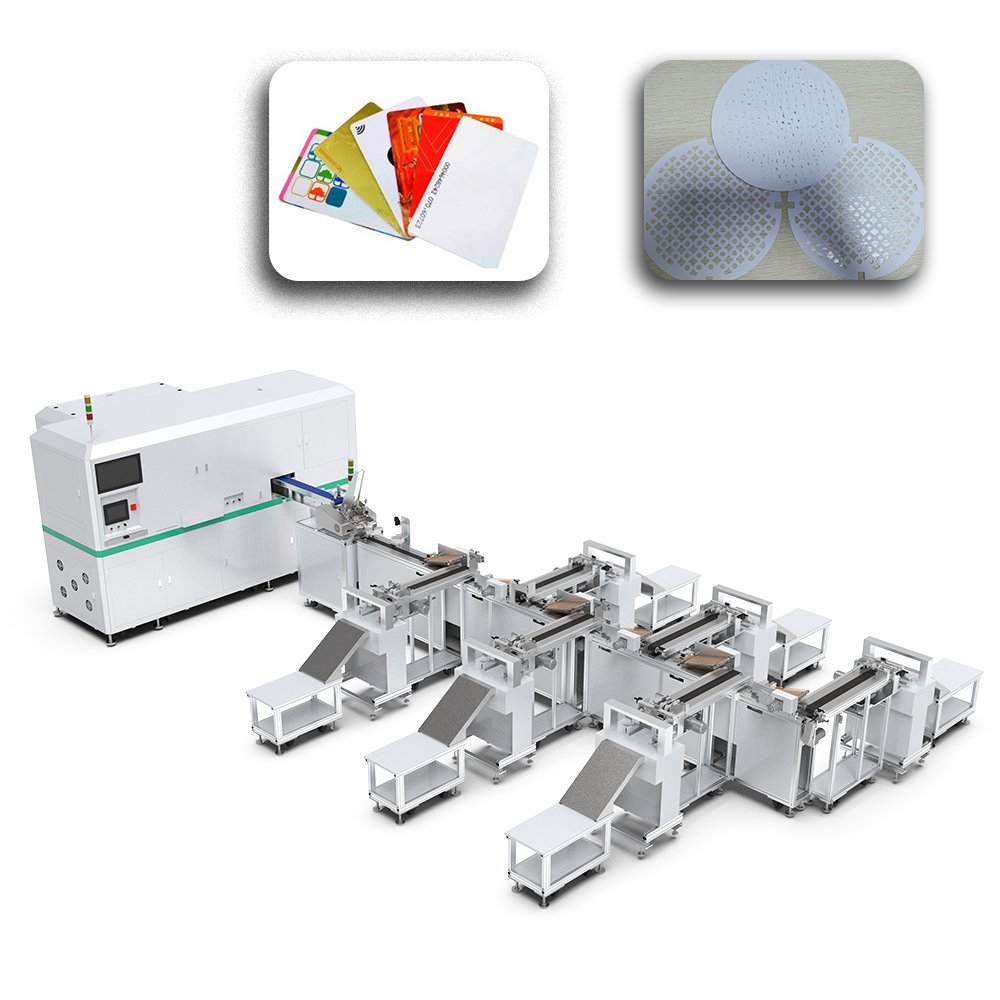

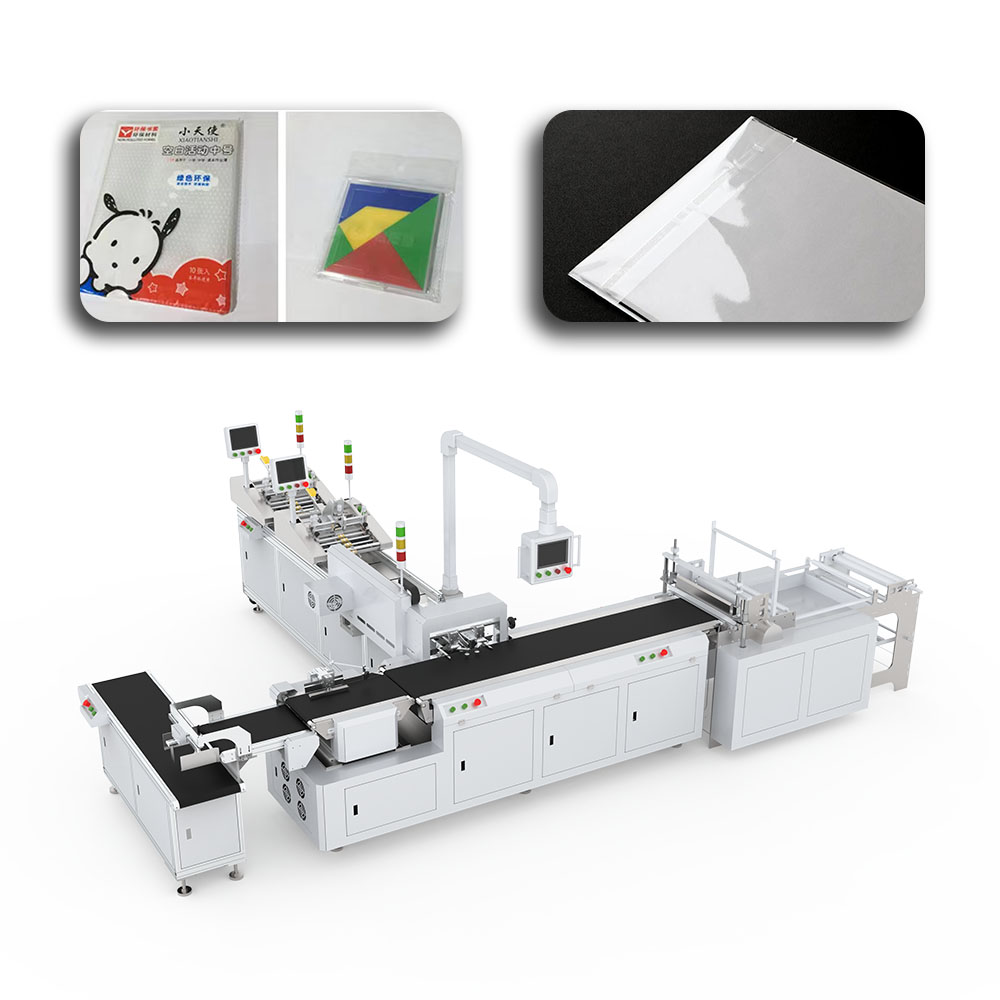

This filter paper die-cutting machine is very flexible. Thanks to its “one machine, multiple uses” feature, it can easily handle die-cutting tasks of different materials and shapes. The main production includes but is not limited to the following products:

Food packaging: steamed bun paper, greaseproof paper, bread paper, cake paper, instant noodle paper, and food paper.

Industrial filtration: filter paper, round filter paper, filter paper ring, filter paper core, paper ring, etc. all belong to industrial filtration. This is the most common use of the equipment and the reason why it is so well known.

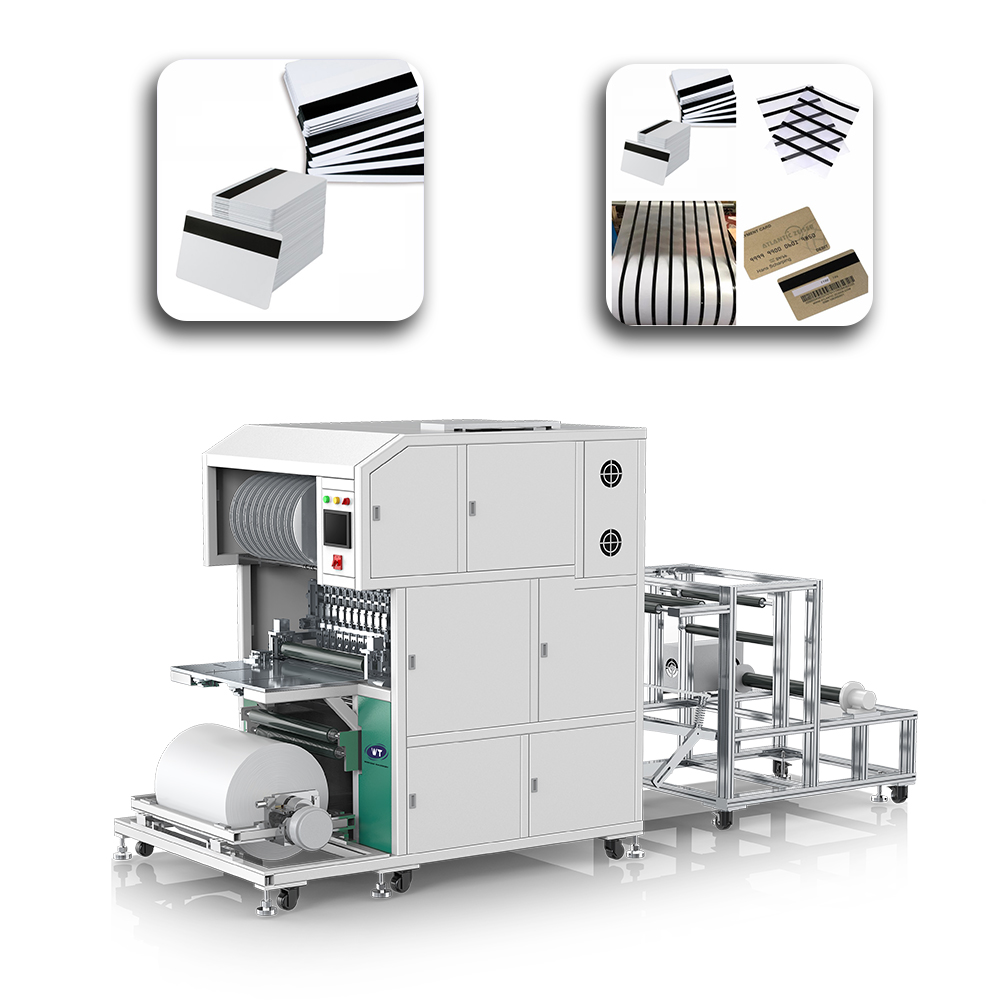

Printing and packaging: labels, wine labels, and dials.

Other products: CD cases, laminated paper, and die-cutting of different book covers and inner pages.

This wide range of uses means that the device can help customers in a variety of fields and maximize the return on their investment.

2. Nine core features of the equipment: Interpretation of professionalism and excellence

1. Precise punching, no burrs, unique texture

The label die-cutting machine adopts a high-precision guiding system and special die to ensure that each punching is as precise as surgery. The finished product has no burrs or fiber residue on the edges. For filter paper rings and filter paper, this means they will filter better and last longer. For wine labels and tags, this means that the printing will be high-end and beautiful, which will directly increase the value of the brand.

2. Strong durability, ensuring continuous and stable production

The body is made of high-strength castings and has been stress-relieved. All core transmission components are from internationally renowned brands. This ensures that the equipment can still maintain very stable and accurate operation even under long-term high-load operation. At the same time, it minimizes downtime for maintenance and helps your large-scale production to continue.

3. True “one machine for multiple purposes”: it can punch and cut books and can also punch and cut filter paper.

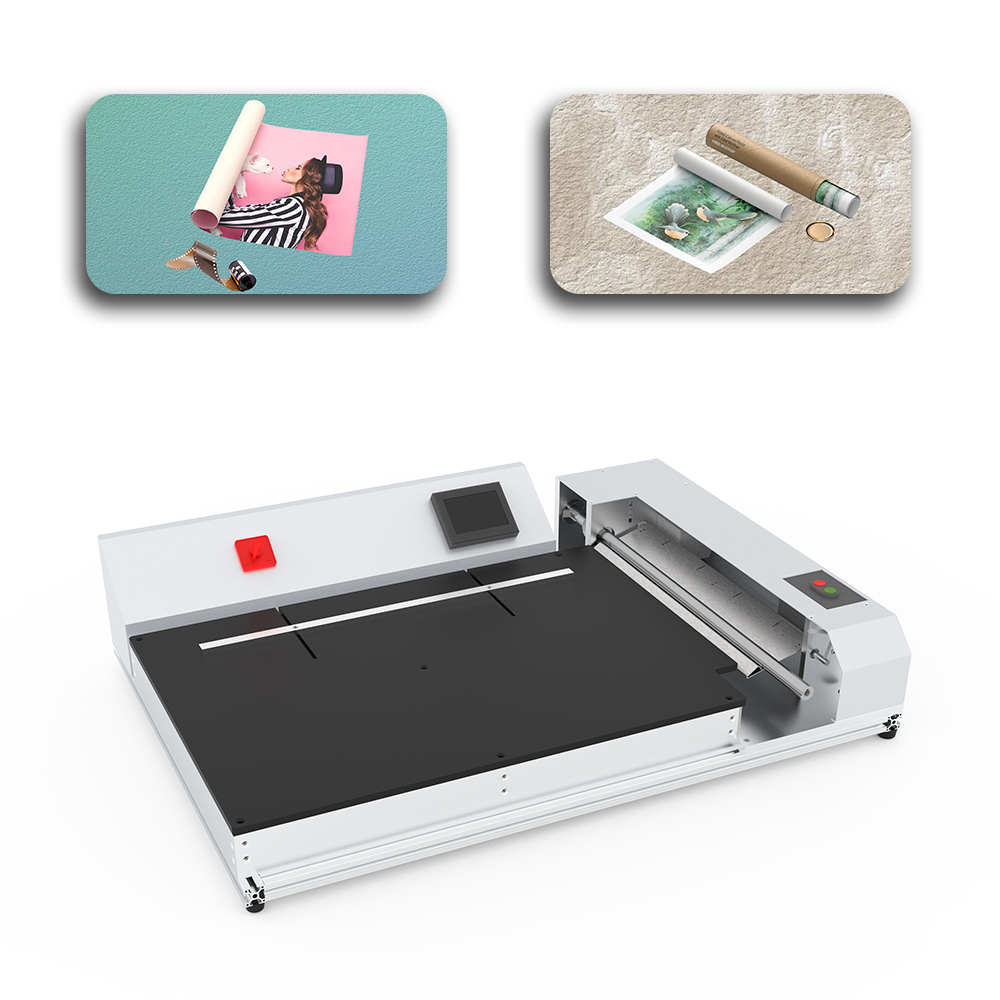

The machine can easily switch between the precise punching of book covers and the cutting of filter paper by changing the mold and parameters. This flexibility greatly expands your business scope, enabling you to quickly meet the diverse order needs of the market and make full use of your production line.

4. The hot stamping technology is used to make the product more valuable.

You can add a high-performance hot foil stamping unit to the machine so that die-cutting and hot foil stamping can be carried out simultaneously. This is a must for making high-end wine labels, watch dials, and gift tags. It saves time and money on post-production steps and makes the product look great, thus greatly improving the quality and value of the product.

5. Mature technology, stable and reliable performance

We have been in the die-cutting equipment industry for 20 years and have added mature technologies that have been verified by the market to the equipment. From the control system to the mechanical structure, every component reflects our efforts to ensure the product is reliable, safe, and easy to use. This means you can buy with confidence and use with peace of mind.

6. Complete solutions to meet your needs

We know that “one size does not fit all.” That’s why we offer in-depth, personalized, comprehensive solutions. Our engineers can tailor the best mold and production plan for you according to your specific material, shape, and production capacity requirements, whether you need a cake paper tray of a specific size or a filter paper core of a specific shape.

7. Automatic sorting and classification

One of the best things about this machine is that it can automatically classify and sort. The integrated vision system or mechanical structure can automatically sort and collect the finished products, such as the round pieces of punched filter paper or labels of different sizes. It has completely changed the traditional manual sorting method, which is slow and prone to errors. Making intelligent production a reality.

8. Powerful 7.5 kW servo drive system

The power core of the label die-cutting machine adopts a 7.5 kW servo system, which can handle a large amount of power. Servo drives are better than traditional mechanical drives because they are faster, more accurate, and use less energy. It provides stable and powerful punching pressure, ensuring that even thicker materials or complex molds can be perfectly made. The energy-saving effect is very obvious.

9. Customize the collection method: order and classification

We have two advanced finished product collection methods that can be matched with the production logic of different customers:

Sequential collection: This method is best suited for the repeated production of a single type of product. Finished products are stacked in the order of production for subsequent packaging.

Collected by category: Different types of finished products (such as steamed bun paper pads and bread paper of different sizes) are automatically sent to different collection boxes through the automatic classification and sorting system. It has realized the assembly line operation of mixed production of multiple varieties.

3. Target customer groups and value presentation

Target customer groups and how to demonstrate value

Food packaging manufacturers: We quickly and safely make all kinds of steamer paper, non-stick oil paper pads, cake paper cups, etc. for you to ensure that food does not come into contact with anything unsafe.

Filter material manufacturers: Filter paper, filter paper rings, and other products are produced by filter material manufacturers. Burr-free punching and cutting to ensure the accuracy and good effect of filtration.

Label and printing companies: Label and printing companies can quickly and easily produce a variety of wine labels and other labels. They can also produce high-end products using hot stamping technology.

Comprehensive paper product processing plants: Due to the characteristics of “one machine for multiple purposes,” they can undertake a wide range of die-cutting orders so that the equipment can be fully utilized.

Concluding remarks

In today’s era of global manufacturing moving toward “Industry 4.0,” having intelligent, efficient, and multi-functional production equipment is the most important factor for enterprises to maintain competitiveness. Our filter paper die-cutting machine is a future-oriented product. It combines precision, durability, automation, and customization, which can not only solve the problems encountered in your current production but also bring unlimited business opportunities for your business growth.

We are a company based in Shenzhen, China, which is known as the global manufacturing innovation center. We have a strong R&D team and a complete global supply chain. We can also provide timely technical support and after-sales service for customers outside China. We sincerely invite global partners to come to negotiate. We will provide you with unique customized solutions to help us jointly open a new chapter in die-cutting manufacturing.