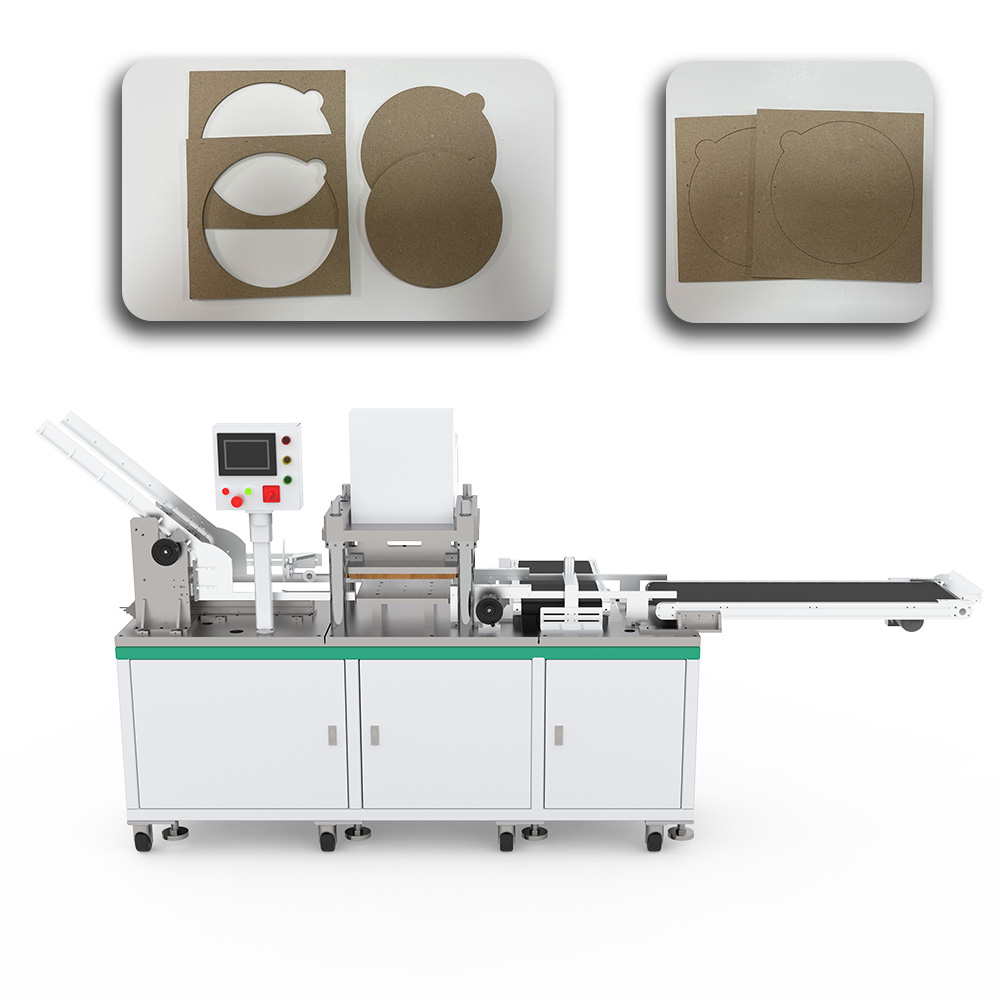

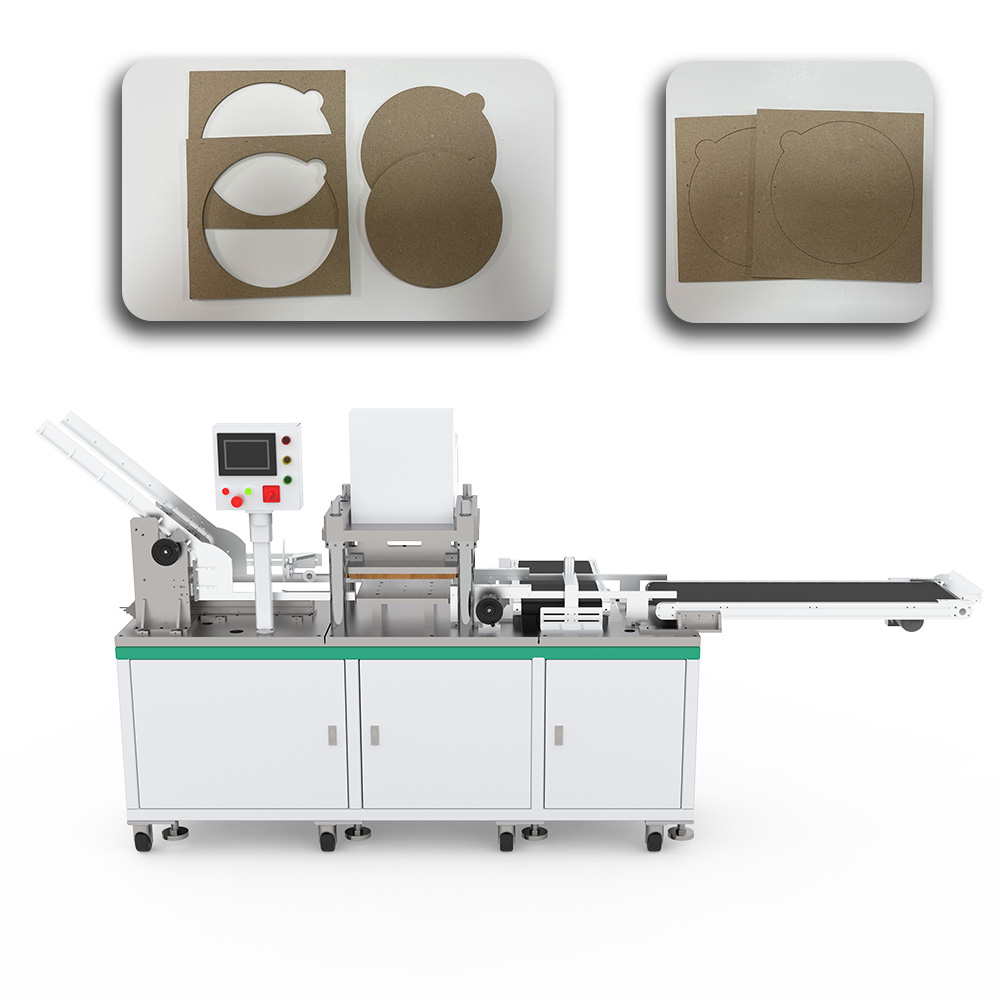

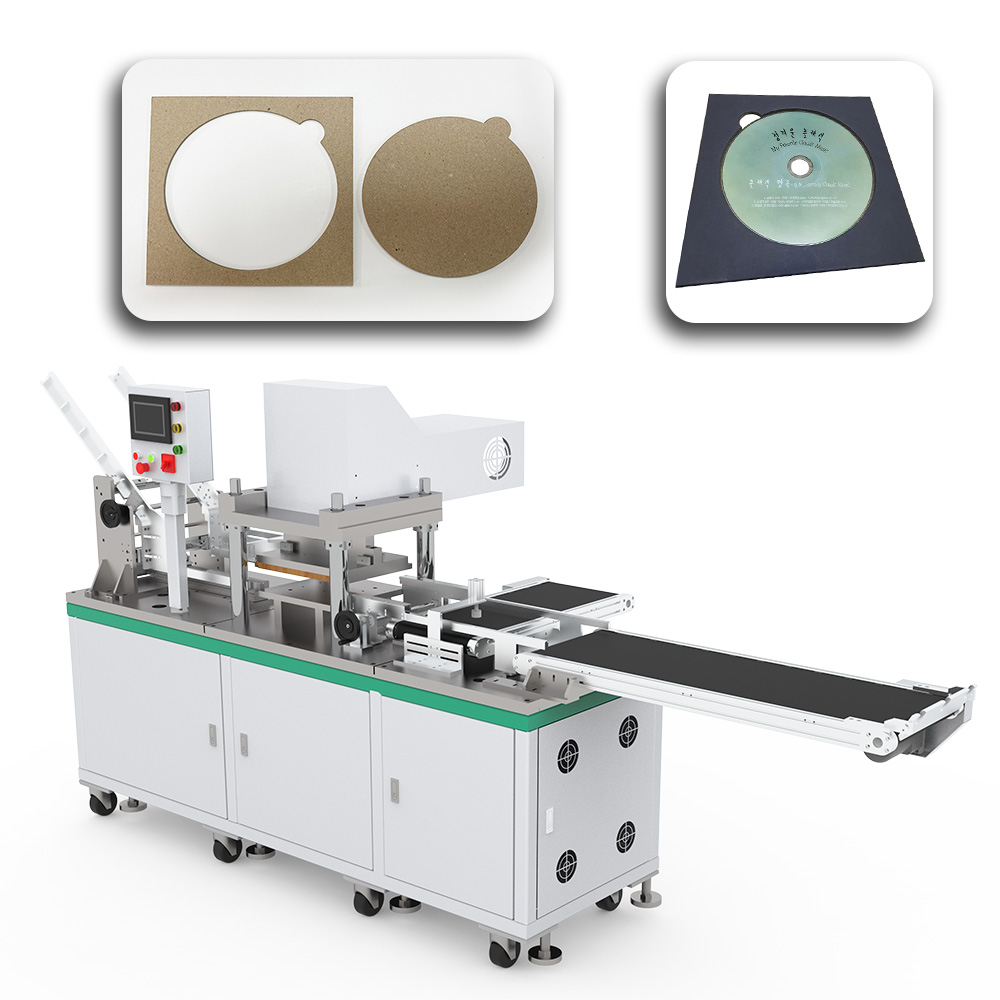

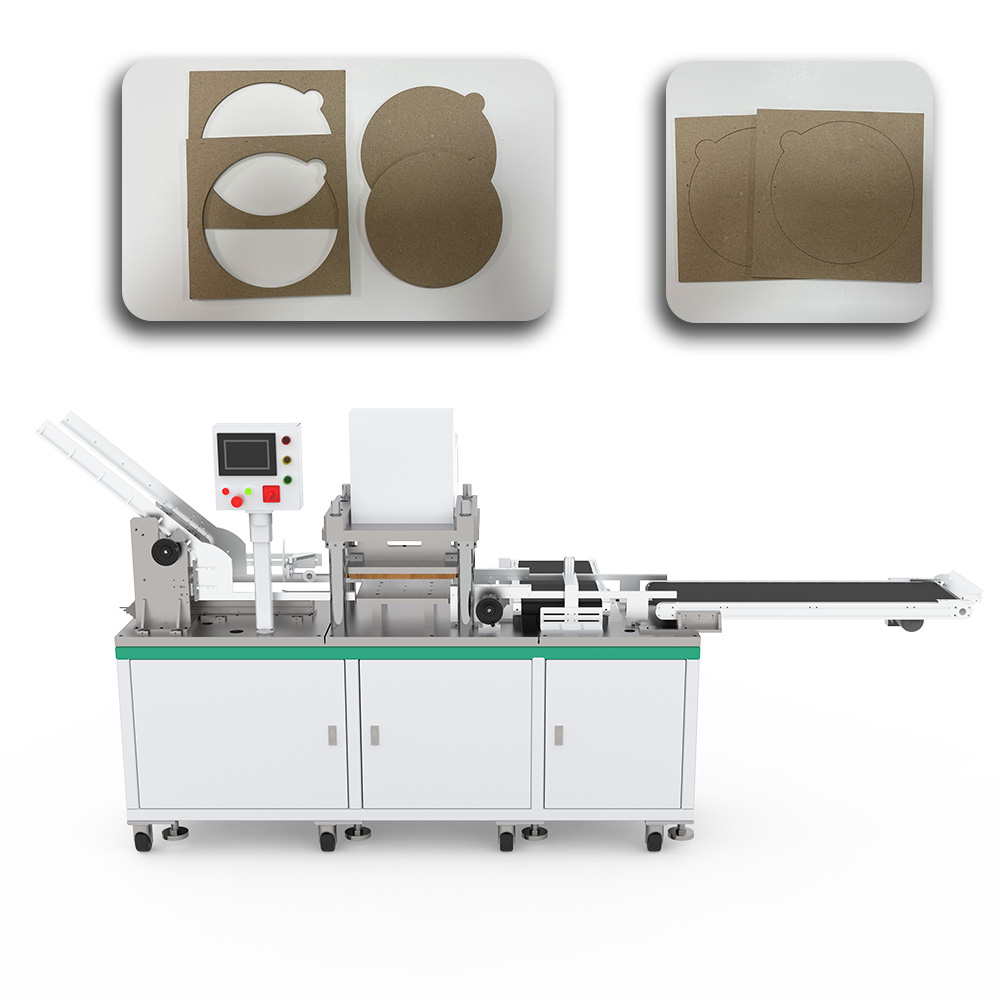

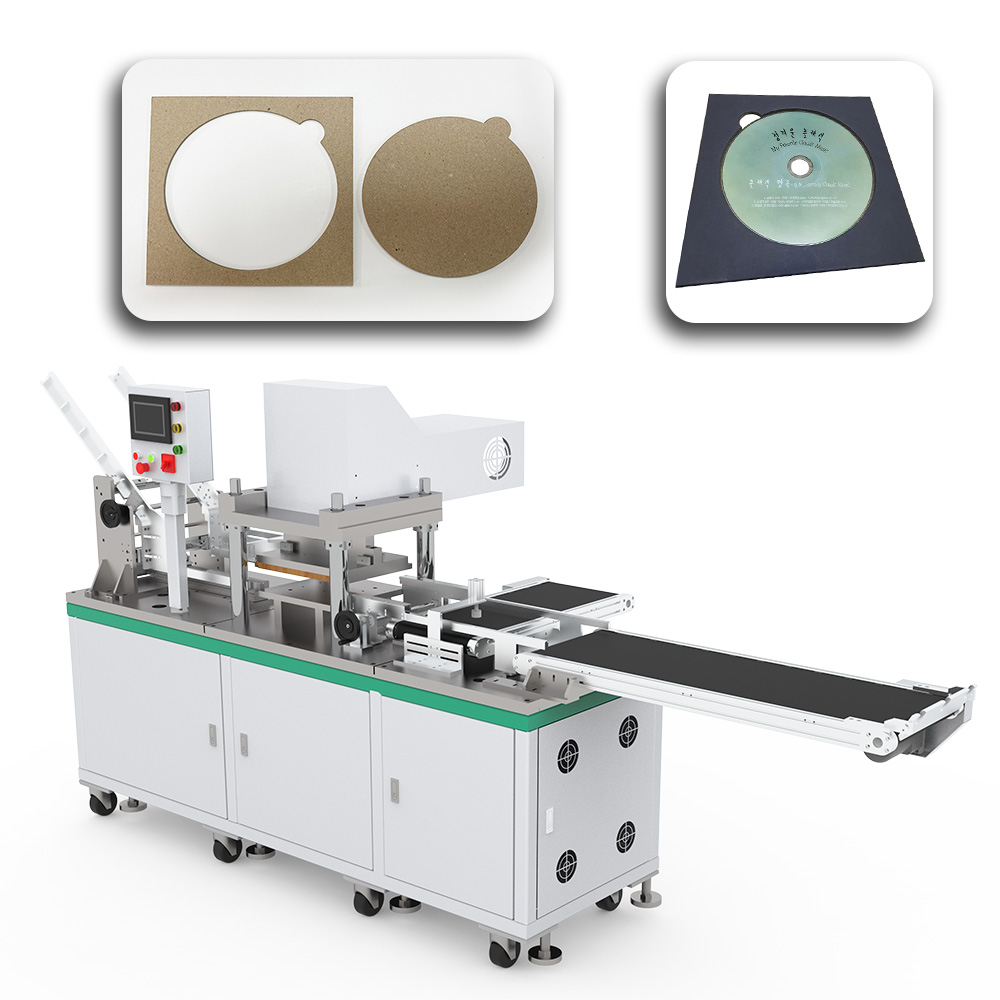

The optical disk die-cutting machine is mainly used for DVD, Blu-ray disk, mini disk, special-shaped disk, game disk, PlayStation, Xbox, laser disk, SACD, Audio DVD, SIM, SD, microSD, and other products. The machine is designed to realize fully automatic, integrated, and efficient production from raw materials to finished products. The whole production cycle, including the post-processing of products, adopts precision machinery, servo control, sensing detection, automatic production logistics, and other technologies.

1. Core production range and industry application background of the equipment

The model is designed to adapt to a variety of recording and recording media products, and its die-cutting and stamping objects can be summarized into two categories:

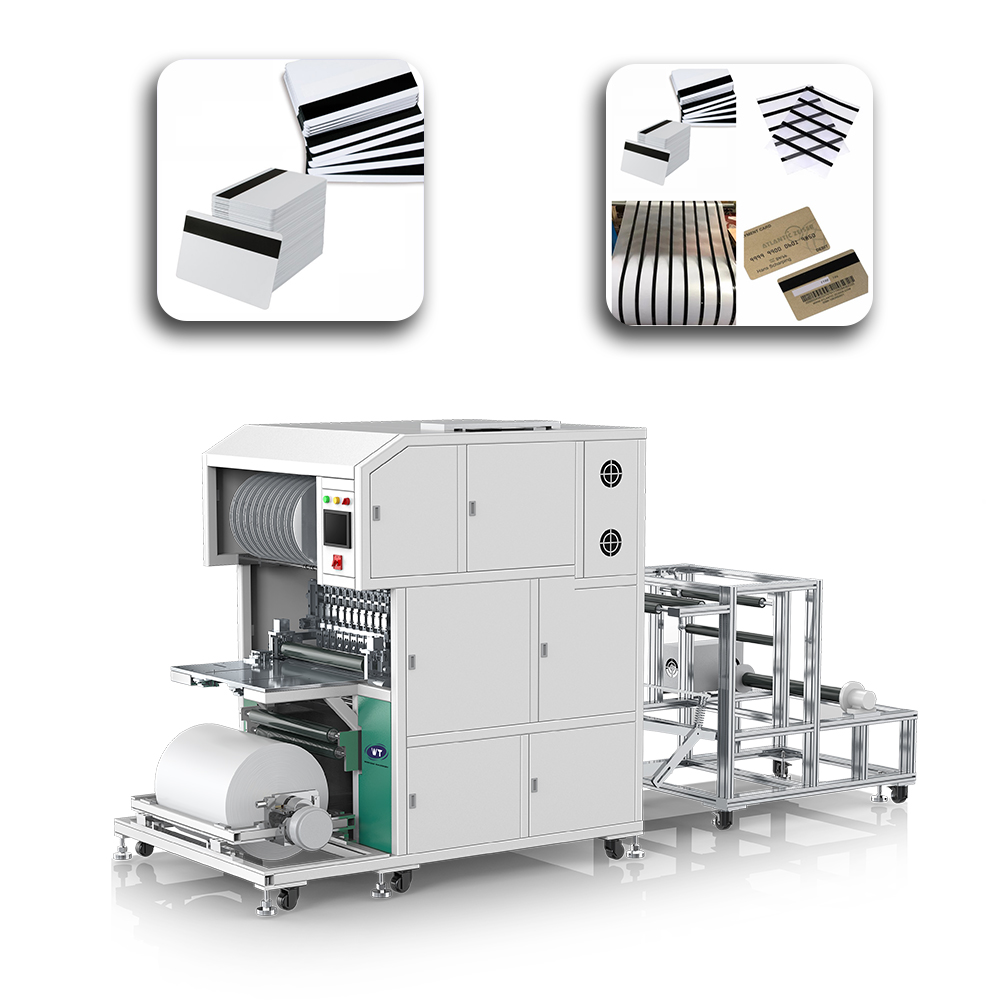

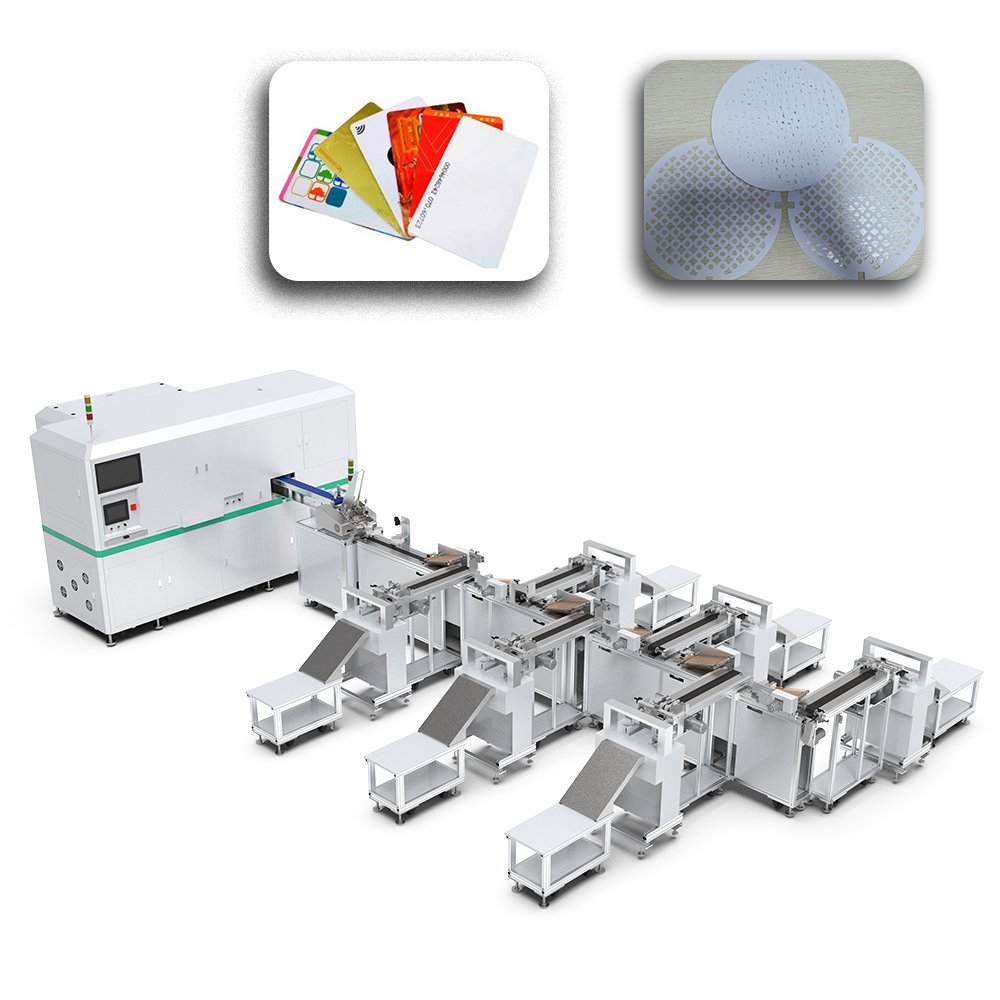

Optical storage media series: including CD, DVD, and Blu-ray disks, as well as mini CDs and other special-shaped disks. The machine is also capable of die-cutting game disks for consoles such as PlayStation and Xbox, as well as laser disks, SACDs, and audio DVDs.

Solid-state memory card series: This reflects the technical extensibility of the equipment. It is capable of producing various SIM cards (including nano-SIM and microSIM) and SD cards (from standard SD to microSD) with high precision. These products are smaller in size and have more extreme requirements for punching accuracy and burr-free.

This speaks to the flexibility of the device. How many types of SIM cards are there (nano, micro, standard SD to microSD cards)? The product is miniaturized, and the stamping should be done according to the sample specifications, and there should be no burrs.

According to the modular design of the equipment, the equipment can use a wide range of materials. And can quickly change the order, reducing the time cost.

2. Core features and in-depth technical analysis of the device

The following will detail the ten important technical features of the CD die-cutting machine and explain the engineering principles and technical advantages that make it work.

1. Excellent punching accuracy and edge quality control

The core of the die-cutting machine is precision. The equipment adopts a number of collaborative designs to control the punching accuracy at the micron level:

Structural basis: The fuselage adopts a high-rigidity integral steel structure frame, which is optimized by finite element analysis and will not bend and fatigue after long-term high-frequency stamping action. Pre-tightening force precision linear guide rail, the worktable does not even have a little bit of shaking.

Core of execution: The special mold is made of special steel and finely ground. This ensures that the stamping process is “shearing” rather than “tearing,” which is the most important means of obtaining burr-free edges, and the blade gap can be fine-tuned according to the characteristics of the material. This feature directly protects the data layer and reading laser on the disk medium so that the optical head of the reading device will not be scratched by the edge burrs.

2. Long-term structural durability and operational stability

Maintenance costs and production line continuity are directly related to the reliability of industrial equipment. The equipment is durable, as evidenced by:

Material science application: Crankshaft and connecting rod are important moving parts, which are made of chromium-molybdenum alloy steel and treated by carburizing, quenching, and deep cooling. The surface hardness can reach above HRC60, while the core still maintains sufficient toughness.

Long-life design: The core drive mechanism works in an oil bath that is completely isolated from the outside world. This not only reduces wear but also prevents the ingress of dust. This enables the equipment to perform continuous production tasks 24 hours a day, 365 days a year, with the mean time between failures (MTBF) set at a very high level.

3. Wide range of multi-functional application expansion

“One machine for multiple uses” is one of the main ideas of the equipment design. Its powerful nominal force and large mold installation space mean that it can be used not only for optical disks, cards, etc. It can be used for:

Printing and packaging industry: Cut or fold hardback book covers and playing card pieces with extreme precision.

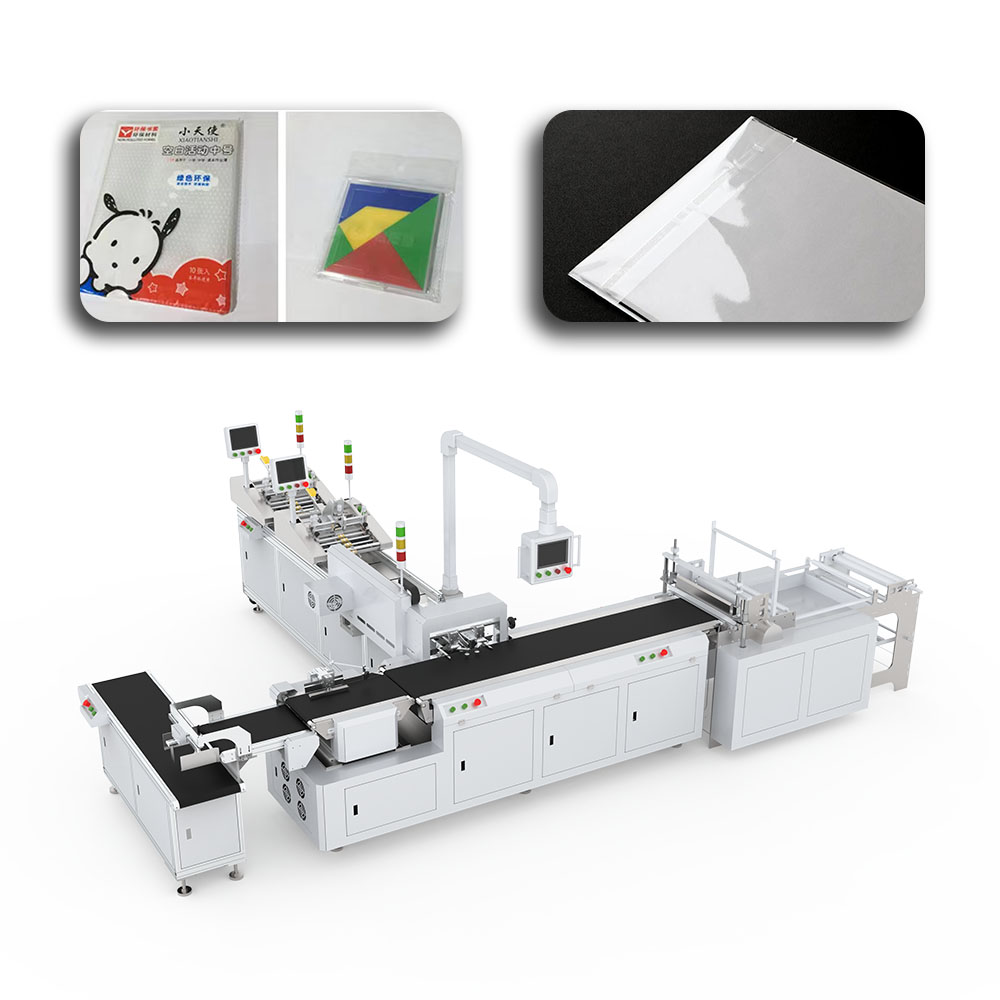

Industrial filtration field: Industrial filter paper and polymer filter membrane are punched into the required shape and pore size.

Flexible Printed Circuit (FPC): Cutting the shape of some thin FPCs. This flexibility makes the device more useful and provides a hardware foundation for users to expand their business.

4. Integrated online hot stamping process module

The unit can be easily connected to an inline hot foil stamping unit to add value to the product. The module is usually placed in front of or behind the die-cutting station and is linked to the main die-cutting action through a precise cam or servo system. Unwinding, hot stamping, and rewinding are all its working processes. These steps can transfer patterns and words with metallic texture (such as gold and silver) to the surface of the disk or card. This integrated design minimizes the risk of product transfer, positioning error, and surface scratches between die-cutting and decoration processes. At the same time, it also makes surface decoration both efficient and high-quality.

5. Technology platform based on mature engineering experience

The control system architecture is optimized using mature technology platforms that have been tested in the market for decades. This means that long-term, large-scale production data has been used to improve its basic design and minimize mechanical defects and weaknesses in the control system. For manufacturers, this means less equipment risk, more stable output quality, and more convenient technical support.

6. Integrated customized overall solution capabilities

We can not only manufacture standard machines but also have engineering capabilities to provide fully customized solutions. This includes the customization of the feeding system, the finished product collection system (such as conveyor belts and robotic palletizing units), and even the control design linked to the front and rear production lines (such as printing machines and packaging machines) according to the user’s plant layout, raw material supply method, finished product logistics needs, etc. This level of customization ensures that the equipment can be added to the user’s existing production environment in the best way.

7. Intelligent automatic classification and sorting system

This is an important part of the system, which shows the degree of automation of the equipment. The system has high-resolution vision sensors or RFID readers, a programmable logic controller (PLC), and a set of electric or pneumatic sorting actuators. The sensors detect the finished products as they come off the production line (based on visual characteristics or built-in chip information). The PLC then sorts the products according to the preset logic (such as type and quality grade) and sends them to different collection channels. Its main working mode is

Collect in sequence: Maintaining the original order in which products were manufactured is beneficial for packaging processes that require matching with specific serial number labels.

Collection by category: Automatically put different products (such as CDs, DVDs, and SD cards) or qualified/unqualified products produced in the same batch into different collection boxes.

8. High-efficiency and energy-saving 7.5 kW servo drive system

The power system abandons the old-fashioned asynchronous motor and clutch/brake combination and replaces it with a 7.5 kW high-torque servo motor. The advantages are:

Precise control: The speed, position, and torque of the stamping process can be controlled digitally in a fully closed loop. Thus, the “soft landing” stamping is realized, and the mold and materials are protected.

High energy efficiency: It uses very little power when idling or running at low speeds, saving 20% to 40% of energy compared to older equipment.

Low noise and maintenance: The noise source and friction brake are removed, making the operation quieter, the mechanical structure simpler, and the maintenance cost lower.

9. Highly flexible customized finished product collection method

The finished goods collection end has many customizable options to meet the needs of various production environments. Users can choose based on the space, automation, and production capacity they need:

Sequential stacking collection: The finished products are neatly stacked in the material basket in the order of discharge.

Sorting conveyor output: Different types of finished products are transported to different stations by different conveyors.

Robot linkage palletizing: The system is linked with industrial robots to realize automatic palletizing and management of finished products.

10. Comprehensive Quality Control and Safety Assurance

The equipment is equipped with multiple real-time monitoring sensors to monitor the stamping pressure, temperature, vibration, etc. If an abnormality is detected, an alarm can be immediately triggered, or the machine can be stopped to avoid the production of a batch of substandard products. The equipment also has safety functions that meet international safety standards (such as CE standards), such as grating safety protection and two-hand start buttons, to ensure the safety of operators.

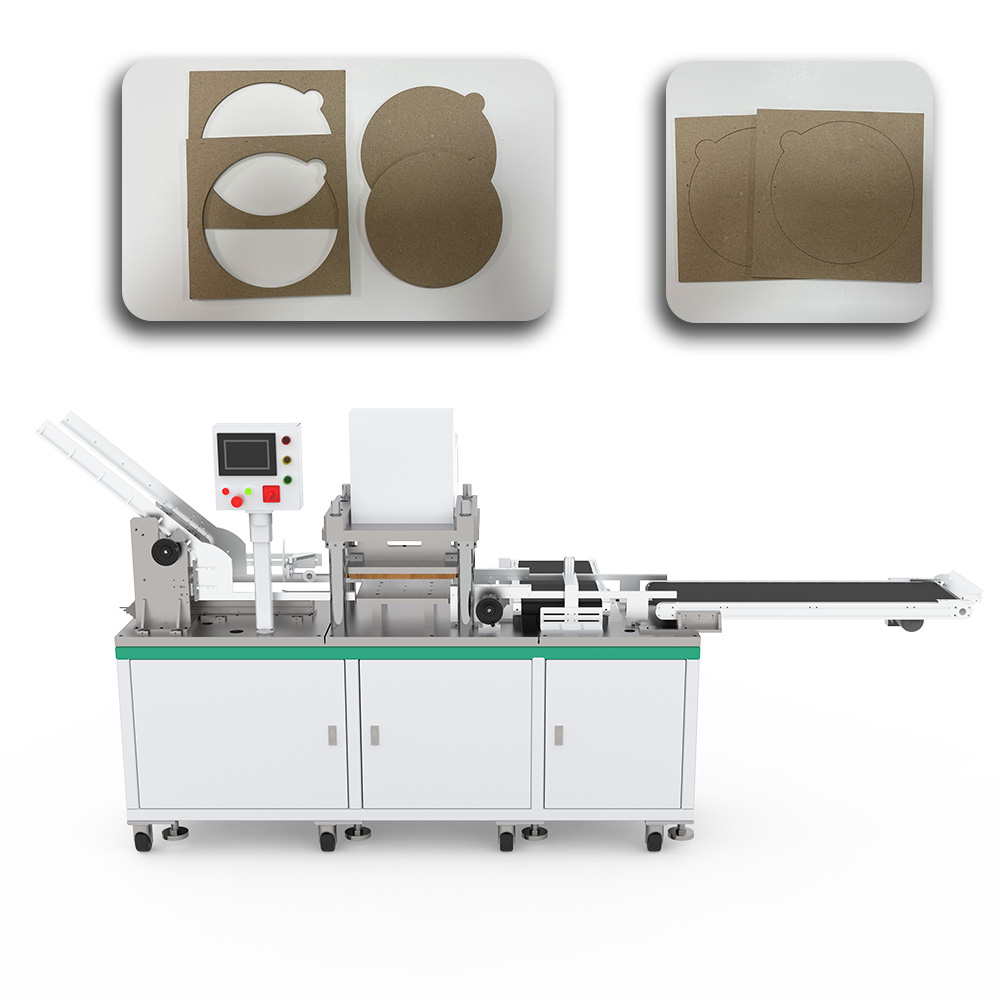

3. Overview of System Architecture and Workflow

The working mode of the CD die-cutting machine is very coordinated, and its main steps can be summarized as:

With positioning: An automatic loader or a person places the raw materials (such as large polycarbonate disk substrates) on the feed table. Then, an optical positioning system or mechanical fixture ensures they are in the correct position.

With auxiliary processing: The servo drive system drives the mold to perform rapid and accurate stamping. The hot stamping process can be carried out simultaneously or at different times at this station.

Scrap stripping: The scrap produced by stamping is automatically stripped and collected.

Finished product output and identification: Move the finished product to the conveyor belt and collect information after passing through the sensor identification area.

Sorting and collection: The PLC controls the sorting mechanism according to the identification results and guides the finished products to the correct collection channel according to the preset mode (sequential or classified) to complete the entire processing cycle. The human-machine interface displays the entire process in real time, and the operator can easily perform recipe management, parameter setting, and status monitoring.

Conclusion

In short, this professional optical disk die-cutting machine is an industrial manufacturing platform with very good connectivity. By combining advanced servo control technology, an intelligent sensing and execution system, and precision mechanical design, it meets the most important needs of precision optical disk and card production in terms of accuracy, efficiency, versatility, and automation.