How does the fully automatic sorting and card punching machine update the intelligent card production process?

blog 2026-02-12 00:59:53 17

Technical field: Tools for making smart cards, systems for automatic punching and very precise sorting of items

You can use paper, film, soft magnetic film, PVC, and ABS as materials.

You can use game cards, smart cards, business cards, anime cards, bank cards, celebrity cards, and small boxes.

Equipment positioning: short, flat, fast – step-by-step feeding and die-cutting solution for small orders

Target market: Printing and packaging businesses in India and around the world.

1.Classification and sorting solutions for chip cards

Making smart cards involves printing, chip packaging, die-cutting, sorting, and putting them into boxes. For a long time, people have believed that the classification and sorting of die-cutting processes is an “invisible bottleneck” because it requires both skilled workers and machines to complete this task. What we really need is the ability to automate a large number of orders with different specifications and small batches. In the past few years, the OEM industry for smart cards and gaming cards in India has developed rapidly. Many orders have multiple categories, scattered orders, and urgent delivery times. In the old manufacturing method, companies usually used one of two methods to classify die-cutting cards. The first method is completely manual sorting, where the staff takes out one card from the trash can at a time and sorts it by chip model, card surface pattern, or serial number. This method requires workers to work continuously for more than 10 hours when the daily order volume exceeds 50000 cards, and the number of errors caused by visual fatigue is rapidly increasing. More importantly, physical labour cannot meet the demand of “collecting cards in order”, which means classifying game cards by star rating or tracking bank card numbers. When two cards appear, the sequence of manual work will change. You need to do it again. The second type is the combination of manual card sorting and online clock-in machines. Some companies have started using old-fashioned automatic clock-in machines to automatically cut things. However, people still need to classify the finished products and waste generated by machines. Traditional equipment requires “nails or connection points” to keep materials sorted in place, so the connection points must be torn off before sorting. This process usually leaves burrs on the edges and curled corners of the card. The scrap rate remains between 2% and 3% for a long time.

From a technical and economic perspective, traditional manual sorting has three main problems that cannot be solved: accuracy limitations; recognition accuracy for patterns with small differences, such as judging their rarity by looking at game cards, greatly affected by fatigue; and an average sorting error rate of 2.3%, which is already the industry limit. The upper limit of efficiency, the upper limit of manual sorting speed, is about 3000 sheets per hour, which cannot be improved by extending working hours; Adjusting the machine usually takes over two hours, which is not fast enough for Indian customers who place orders today and need samples tomorrow. In this situation, the Indian printing industry needs a machine that can quickly identify and classify things, process very small batches of samples, and ensure smooth edges of cards. This is the technical entry point for machines, which can classify, categorise, and punch holes for things on their own.

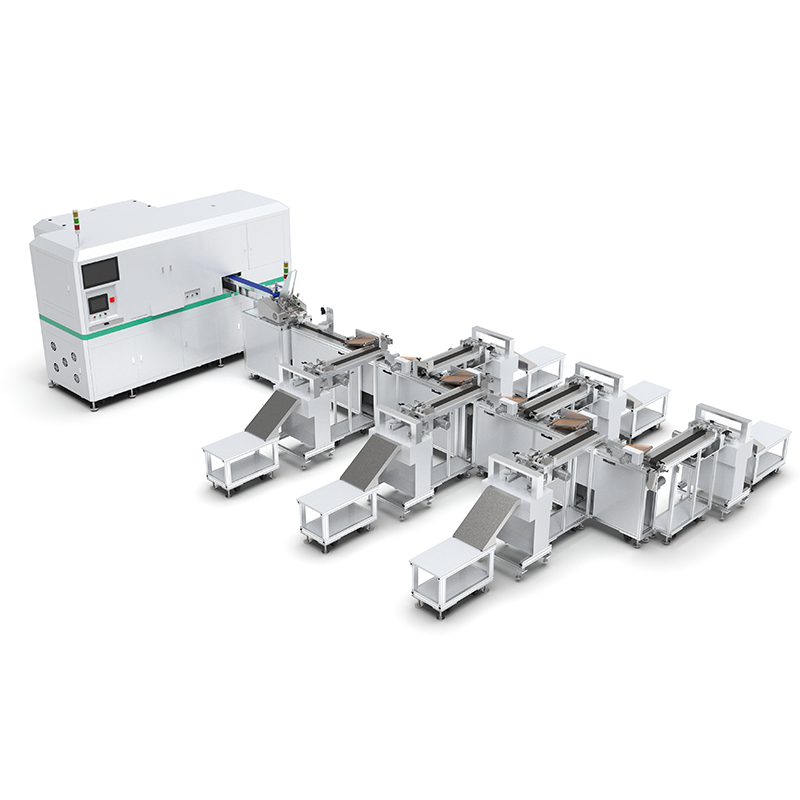

2. Working principle of fully automatic sorting and card punching machine

Fully automatic sorting and punching machines are not just better versions of old punching machines. It is a device that operates at the system level, using the same set of servo control logic for die-cutting, visual inspection, and intelligent sorting. In short, the technical architecture consists of the following parts: the foundation is step-by-step feeding, the eyes are visual correction, the brain is artificial intelligence classification, and the hands are servo punching. This device is different from traditional “continuous rolling feeding” because it adopts precise step-by-step feeding technology. In traditional die-cutting machines, the material belt moves forward continuously, with a set feeding distance for each step. When a material is under tension, it will stretch uncontrollably. This makes it more likely for errors to occur in the subsequent punching and cutting positions. The punch press with automatic sorting and classification has several sets of servo motors to control the feeding rollers. The encoder provides real-time accurate feed distance for each step, with an accuracy of micrometres. The control system changes the next feed distance based on the deviation between the measured value and the theoretical value. After calibration with a laser interferometer, the feed accuracy of the machine can reach ± 0.05 mm.

When the material arrives at the die-cutting station, the visual correction and positioning system will take over. The system is equipped with a 2-megapixel industrial camera that can sample the pattern edges or position crosshairs on the printing plate at the sub-pixel level. The algorithm in this device calculates the material’s offset in the X/Y axis and angular direction in real time. Then, it writes the compensation data into the motion control instructions of the servo stamping module. The traditional visual system only recognises ‘existence or non-existence’, which is different from this. This means that even if there are overprinting errors during the upstream printing process or slight skewing during the feeding process, the stamping die can still accurately follow the actual position of each card. It can be fully cut and punched without the need for nail or connection points. The front-end imaging, intermediate computing, and back-end execution must work together to optimise the entire chain in order to sort the recognition at the millisecond level. When the completed cards are sent to the sorting station, the high-speed camera takes photos of the card surface at a speed of 60 frames per second. Afterwards, the AI algorithm completes feature extraction and classification judgement within 30 milliseconds. Due to the logic behind classification, you can place rules in multiple layers. For example, the system can determine whether the card surface is red peach A or black peach K, the serial number is within the preset range, and there are scratches on the chip surface. The sorting execution mechanism obtains the judgement result immediately through industrial Ethernet. Then, in the next cycle of moving items, the pneumatic fork pushes the card into the box on the right side. This process is a major advancement in engineering, as it keeps the system response delay within 50 milliseconds. It only takes one tenth of a person’s blink time. The AI vision system has a lot of extra work to do because when the device is running at a speed of 8000 cards per hour, it only has 450 milliseconds to process each card.

3. Precise sorting technology of fully automatic sorting and card punching machine

The main goal of smart card production classification is not to “separate different patterns”, but to “deliver each card to its unique order location”. Games typically use flashcards, regular cards, signature cards, and other types of cards. There needs to be a clear distinction between test cards, finished cards, and expired cards for bank cards. Single visual recognition may not work in two situations: Scene A is a bus card with the same card pattern, but the data stored in the chip is different, such as different denominations; Scene B is the serial number of the laser-engraved card surface. The angle of light can easily affect your ability to see things. The fully automatic sorting and clocking machine has a dual verification system, using optical identification and radio frequency identification in the same sorting channel.

The system has an OCR algorithm tailored specifically for the card industry, so it can accurately recognise characters using different methods such as convex codes, spray codes, and laser codes. This is the first step in recognising OCR characters and decoding QR codes. On the other hand, the algorithm has been trained on tens of thousands of game cards and bank card samples, so it can handle printing errors such as hot stamping backgrounds, laser reflections, and fine line interference. If the OCR confidence level is below a certain level, the system will automatically turn on more lights or take more photos from different angles to ensure that errors will not occur due to the poor quality of a single frame image. To check the second level of RFID RF reading, you need to place an ultra-high frequency read-write module at the product sorting station. Like contactless smart cards and NFC gaming cards, these modules have built-in RF chips. When the card passes through the recognition area, the reader will wake up the chip within 10 milliseconds. Then, it reads the unique identification code and user data area. Then, the system compares this UID with the OCR-recognised serial number. For example, the “card number 10001” printed on the surface of the card must match exactly with the “10001” written inside the chip; otherwise, it will be considered a chip write error and sent to the waste bin. For industrial-grade traceability requirements, this dual verification system makes sorting smart cards more reliable. More importantly, the data used for verification itself does not exist. The built-in database of the device tracks the recognition results, judgement time, and classification destination of each card in real time and sends it to the enterprise MES system using the MQTT protocol. This means that when Indian customers request a “serial number distribution record for each gold card”, manufacturers can directly export sorting logs from the system without manually counting again.

The RFID module can quickly switch to reading barcodes or QR codes of paper cards such as poker cards, star cards, and anime cards without chips. The device still has the logical integrity of double verification, but the second verification has changed from “reading the chip” to “reading the encapsulated code”. This modular design allows the same device to easily switch between smart card and paper card orders. Setting up the machine only takes 15 minutes.

4. Practical case: Classification and sorting error rate reduced from 2.3% to 0.05%

In the NCR region of Delhi, India, there is a medium-sized factory that produces smart cards, campus cards, and gaming loyalty cards for telecommunications companies. In 2024, factories will have to work very hard to meet the deadline. With the development of the gaming industry, more and more people in India are looking for “blind box game cards”. Each box of built-in cards must contain a certain number of rare cards, and the serial numbers cannot be the same or omitted. The first production line of the factory has two old-fashioned automatic clock-in machines and fifteen people for comprehensive inspection and classification. As part of the production process, the card punching machine mixes waste and finished products into strips. Four people are responsible for dismantling the connection points. Eleven people sat in front of the lighting station, examining the surface patterns of the cards one by one. Then, they packed them into boxes made of vacuum-formed plastic. In this mode, three major issues arise: the sorting error rate remains between 2.1% and 2.3% for a long time, and there are many customer complaints. During the process of tearing the connection point, the deburring rate of the card edge is as high as 4%. They do not accept high-end orders, and it took them over three hours to receive new orders. Due to frequent changes in specifications, achieving daily production goals is much more difficult.

In the third quarter of 2024, the factory imported a fully automatic sorting and sorting press from Shenzhen. They also connected it to the backend automated packaging line to make it work. The device’s settings include a 7.5kW servo stamping power reserve, sufficient soft magnetic plates, and 0.76mm PVC card edges without white edges. For sorting by UID in the card, visual correction, OCR recognition, and RFID reading were all used three times. The finished product collection adopts a “classified collection mode”, with 12 silos, each with a different number of rare cards. Replacing the mould for lightweight wooden parts takes 2 minutes and 50 seconds, and the entire order switching process, including importing parameters, takes 14 minutes. Actual test data shows that after 90 days online, the sorting error rate decreased from 2.3% to 0.05%. This is a 97.8% improvement. The number of broken edge burrs decreased from 4.1% to 0.3%, an increase of 92.7%. It used to take 185 minutes to replace a machine, but now it only takes 14 minutes. This is a 92.4% improvement. The production capacity of a shift increased from 21000 sheets to 64000 sheets within 8 hours, an increase of 204%.

A classification error rate of 0.05% means that there are only 5 classification errors per 10000 cards. Multiple adhesion or physical defects in the incoming materials may be the main reasons for these five errors. This is because RFID dual authentication almost completely prevents chip data from being read incorrectly. The factory manager stated that due to card issues, they must pay approximately 150000 rupees per month to Delhi Telecom Company. Since the equipment was put into use, this cost has been reduced to zero. More importantly, the sampling capability has been greatly improved. Due to the step-by-step feeding structure of the equipment, only 3 to 5 pieces of material can be fed at a time for trial flushing. You don’t need to make the entire cutting board or replace the entire roll of material strip. Thanks to the new 2-minute mould-changing technology, the factory can now promise Indian customers that they will ‘produce the first sample within 2 hours after confirmation’. This fast response time enables the factory to handle exclusive OEM orders for several new Indian gaming card startup brands.

Summary

The innovation of fully automatic sorting and punching machines in the production process of smart cards is to change the way cards are processed after production. They are no longer ‘labour-intensive inspection processes’ but ‘data-intensive information processes’. In traditional production logic, sorting is a passive inspection of formed products. In the new way of thinking, sorting is the final step in the production process. This device not only knows what the card should look like but also its true appearance, whether the data is correct, and which box it should be placed in. From a technical perspective, the industry value is as follows: precision, visual correction, and step-by-step feed lock the cutting position error within 0.10 mm, and the edge roughness is less than Ra 0.8 m, so there is no need for secondary trimming; Flexibility, 2-minute mould replacement, and 15-minute full-process machine adjustment make orders with a minimum order quantity of 100 more economical; High efficiency, 7.5kW servo power supply supports stable production of 8000 sheets of paper.

Due to the widespread adoption of this technology route, the competition in business card printing is shifting from “who can complete it quickly” to “who can accurately complete it, exchange it frequently, and have complete data”. This is true for the printing and packaging industries in India and around the world. Companies that can perform small-batch precision die-cutting and intelligent sorting in milliseconds will create long-term technological barriers in high-value niche markets such as gaming cards, smart cards, and star cards.