How does the bank card punching machine solve the production problems of short cycle and large output?

blog 2026-02-06 00:32:00 15

In the printing and card-making industry, the traditional production mode has been difficult to meet the growing demand for short-cycle and high-yield orders such as game point cards, animation cards, and smart cards. This article will analyze the traditional production bottleneck from a professional and technical perspective. Then, it will systematically elaborate on how the fully automatic card punching production line based on the bank card punching machine uses new technologies to achieve efficient, accurate, and flexible modern production. It also gives printing companies a reliable answer.

Bottleneck analysis of traditional card-charging technology in the peak season of points cards

Game cards, star cards, and other products often have the characteristic of strong timeliness. New games, popular animation broadcasts, holiday promotions, etc., orders often show a rapid growth of “short cycle, large batch.” The old card-punching method has many problems in these cases:

1. Low production efficiency and difficult to cope with peak demand: Semi-automatic or manual die-cutting machines require manual paper feeding and paper collection, the production speed is slow, and the operators are prone to fatigue. When faced with urgent orders of millions of sheets, it is often necessary to increase a large number of personnel and equipment to start work at the same time. This makes management more difficult and also shows that there is an upper limit to production capacity, which can easily cause delays in delivery.

2. Long preparation time for machine adjustment and inflexible order switching: When changing card molds of different sizes, traditional equipment requires a long time for adjustment and alignment. This may take 30 minutes to several hours. This process takes a long time for small and large volume orders of game cards or smart cards that require frequent switching between different sizes and patterns. This reduces the overall equipment effectiveness (OEE).

3. Precision problems are linked to material waste: Traditional die-cutting processes often require the setting of “nail mouths” and “connection points” in the layout to ensure the smoothness of the material and the falling off of the finished product. This not only increases the difficulty of waste removal in the later stage but also may make the edges of the cards not beautiful enough. High-end game cards and collection cards are difficult to guarantee quality. Manual feeding may also make mistakes, resulting in inaccurate overprinting and offset die-cutting positions, reducing the yield rate.

4. Rising labor costs and poor quality stability: Traditional processes require a large number of skilled workers. In a world of rising labor costs, this is a huge ongoing cost. Manual operation is uncontrollable, and the quality of products varies, making it difficult to get the same products each time.

5. The next sorting process is difficult: After die-cutting, manual collection, counting, and packaging are required, and the production efficiency is difficult to improve.

These issues make it difficult for printing companies, especially in emerging markets such as India, to quickly meet customer demand and take on orders that can make them a lot of money.

wentong solutions enable 24-hour uninterrupted production.

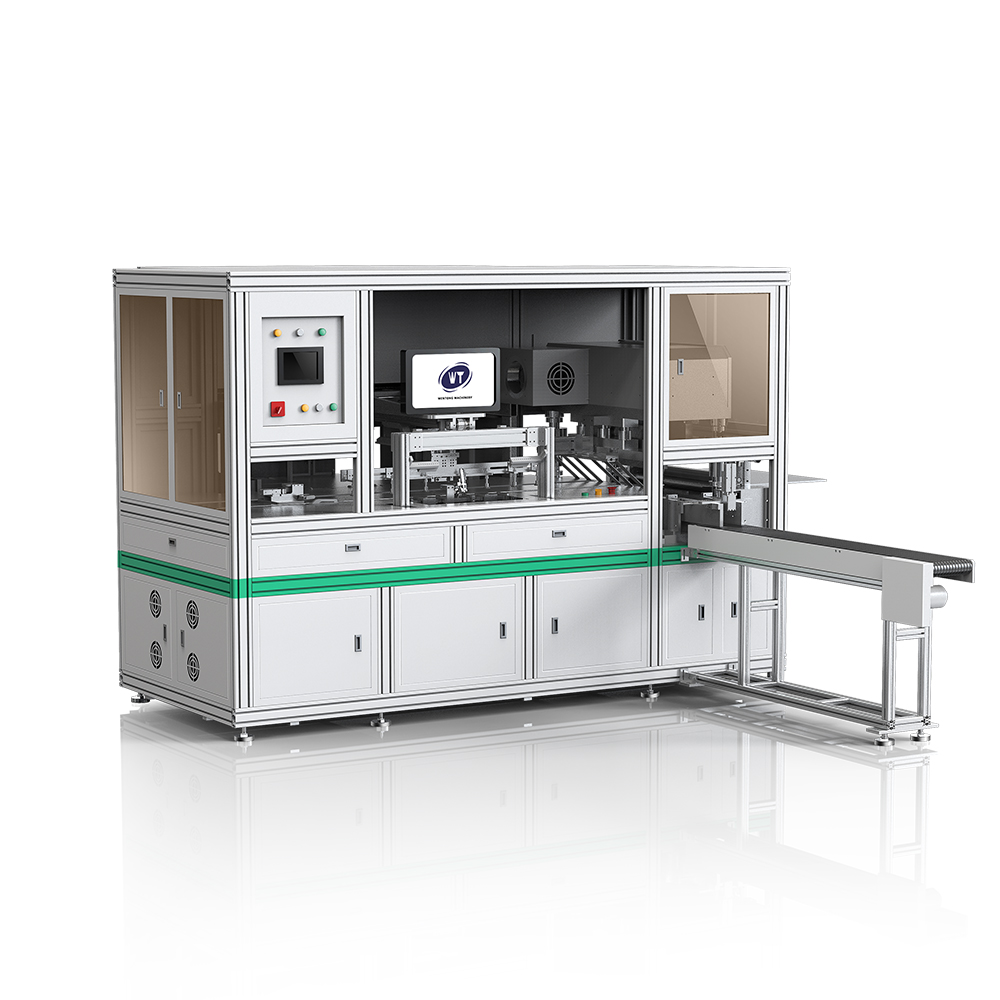

The fully automated production line with a high-precision and high-automation bank card punching machine as the core is a simple solution to the above-mentioned industry problems. This machine is designed for cutting card-like items such as business cards, smart cards, game cards, playing cards, animation cards, bank cards, and star cards. Its technical features are perfectly matched with the production needs of “short, flat, and fast.”

Technical performance analysis of bank card punching machine:

1. Fully automatic precision feeding and visual correction system: This machine adopts a high-precision servo-driven feeding system and is equipped with an advanced camera image correction and positioning system. Before the material enters the die-cutting area, the vision system will automatically find the positioning mark on the printed pattern. Then the position of the material in the X, Y, and θ angle directions is changed in real time to ensure that each stamping is perfectly aligned with the printed pattern. Thus, the “step-by-step precision feeding” is realized, which ensures the very precise positioning of the finished product and guarantees the quality of the card edge from the source without burrs.

2. Stepping feed die-cutting technology without connection points: The unique stepping feed die-cutting technology is very suitable for small batch production or production tasks that require a large amount of materials. The tool does not need to use the traditional “nail mouth,” “connection point,” and other methods to connect the material and the finished product together. Through precise vacuum adsorption or mechanical positioning, the material can be moved, and the finished product can be separated quickly and reliably. This not only makes it easier to plan the layout at the beginning but also saves time when the connection points need to be removed later. It also makes the edges of the card stronger and more attractive.

3. Quick mold change and machine adjustment capability: As the equipment adopts a light wooden mold or standardized magnetic template and has a quick clamping and positioning mechanism, the mold change time is only 2-3 minutes. The CNC system records the production process settings of each product. The order change time can be controlled within 15 minutes. This makes the equipment more flexible in handling small batch and multi-variety orders and also facilitates the customer making samples.

4. The equipment can easily handle many different card-based materials, such as ordinary paper, coated paper, PVC, PET, ABS, and other films, as well as soft magnetic sheets, etc. And it is very stable and powerful. The core punching power comes from the 7.5 kW high-torque servo motor, which gives it strong and stable punching power, and even the hardest materials can be easily penetrated. The motor also has the characteristics of quietness, power saving, and long service life.

5. Intelligent finished product collection and back-end docking: The equipment has two fast finished product collection methods: (1) collect in order to ensure that the card order is not chaotic, which is convenient for subsequent automatic coding or packaging; (2) collect by category, and the layouts of different patterns cut out at one time can be automatically sorted and classified. The equipment also has the interface of the overall solution of the back-end product packaging. It can be connected in series with an automatic card stacking machine, a counting machine, a packaging machine, etc. to form a real end-to-end automatic production line.

6. More versatile: The machine can make many different things, such as small boxes for packaging, precision washers for packaging, etc. It can make more things because it can die-cut with high precision.

The fully automatic bank card punching machine can handle the entire process from loading the coil or sheet to automatic error correction, precise punching, separation and collection of finished products, and removal of waste. This means it can run 24 hours a day, seven days a week, and do the job efficiently. This frees up workers from repeating the same tasks over and over again, allowing them to focus on quality control and production management.

How can a bank card punching machine replace the annual benefit report of three work stations?

You should always choose to buy based on how much money the automation equipment can save you. We take a standard automatic bank card punching machine as an example to show how much benefit it can create each year after replacing the three positions of traditional feeding/operator, quality inspector, and receiving and sorting worker.

Some basic ideas:

The average cost of a workstation in the market is 80,000 yuan per year, including wages, social security, management, training, and other expenses.

The equipment runs for about 20 hours every day.

The old production method produced an average of 2,000 sheets per hour with a 95% pass rate.

The average speed of the fully automatic card punching machine is 3,500 cards per hour, with a pass rate of 99.5%.

The average power consumption of the equipment (including the auxiliary system) is 10 kW, and the electricity fee is 1.2 yuan/kWh.

Rough estimate of annual benefit analysis:

Direct labor cost savings:

Three different work locations

Three times the annual labor cost: 3 × 80,000 yuan = 240,000 yuan.

The increase in efficiency has led to an increase in production capacity:

Normal daily output in 20 hours: 20 h × 2000 sheets/h = 40000 sheets.

The automatic line produces 70,000 sheets per day, 20 hours per day, and 3,500 sheets per hour.

The daily output increased by (70,000 – 40,000) / 40,000 = 75%.

This means that the number of orders that can be taken has increased significantly, but the working hours have not increased. Or, the same orders can be completed faster, thereby accelerating the return of funds.

More people pass, less waste:

If the average cost of each card is 0.1 yuan, and 70,000 cards are made every day,

The normal amount of waste paper is 70,000 sheets/95%×5%×0.1 yuan, which is about 368 US dollars.

The automatic line throws away 70,000 pieces of waste paper every day, worth about $35.

We save $368-$35=$333 on material waste every day.

Calculated on the basis of 300 days, the annual savings are 333 yuan × 300 days = 99,900 US dollars.

Rising energy and maintenance costs over time:

The annual electricity bill is 72,000 yuan, i.e., 20 hours/day × 300 days × 10 kW × 1.2 yuan/kWh.

Estimated annual maintenance cost: RMB 15,000.

Total additional costs for operating the business: 87,000 yen.

The annual net economic benefit is:

A total of 339,900 yuan was saved, including 240,000 yuan in labor costs and 99,900 yuan in material waste costs.

The new price is 339,900 yen – 87,000 yen = 252,900 yen.

In summary, the data shows that replacing the three related stations with a fully automatic bank card punching machine can save about 250,000 yuan a year by reducing direct labor and waste costs alone. This does not include the indirect benefits of shorter delivery times, increased customer satisfaction, and increased market competitiveness, as well as possible order growth. Typically, you can recover your equipment investment in one to two years.

Conclusion

The global market trend for card products such as game cards is “short cycle, large volume.” This is especially true for fast-growing markets such as India, where cost sensitivity and fast delivery times are critical. For this reason, upgrading and replacing production equipment is no longer a possibility but a necessity. The core equipment of the solution, the high-precision fully automatic bank card punching machine, solves the problems of slow production speed, low precision, and poor flexibility of traditional production. It uses the technical advantages of visual correction and positioning, step-by-step precision feeding, rapid mold machine replacement, wide material adaptability, and intelligent material collection to solve the problems of slow production speed, low precision, and poor flexibility of traditional production.

The equipment can not only continuously produce high-quality products but also bring real economic returns to enterprises quickly by replacing a large number of workers, improving efficiency, and reducing waste. Printing and card manufacturing companies around the world, especially in India, need to invest in such automated equipment to improve their core competitiveness and seize market opportunities. It transforms the manufacturing method from “skill,” relying on practical experience, to “precision manufacturing engineering,” which is stable, reliable, and can be repeated. This provides enterprises with a strong technical and cost basis in the competitive world.