Как машина для резки игральных карт превращает игральные карты из листового материала в отдельные карты?

блог 2024-11-17 23:57:45 9

Playing Card Cutting Machine

Playing cards have been a staple of entertainment and strategy for centuries. From simple games of chance to complex strategic battles, these small rectangular pieces of cardstock have captured the imagination of people across the globe. But have you ever wondered how these cards are made? In this blog post, we will delve into the fascinating process of cutting sheet materials to create individual playing cards, exploring the history, technology, and craftsmanship behind this age-old art.

The History of Playing Cards

Before we discuss the cutting process, it’s essential to understand the history of playing cards. The origins of playing cards can be traced back to China in the 9th century, with the earliest known cards being paper dominoes. By the 14th century, the modern deck of 52 cards had evolved in Europe, featuring four suits and a variety of ranks that we recognize today.

The Making of a Deck: From Paper to Cards

1. Paper Selection and Preparation

The journey of a playing card begins with the selection of high-quality paper. The paper must be durable, flexible, and able to withstand the wear and tear of shuffling and playing. Brands often use a blend of materials, including cotton and paper pulp, to achieve the desired texture and strength.

2. Design and Printing

Once the paper is chosen, the next step is designing the cards. This involves creating the artwork for the faces and backs of the cards, as well as the number cards and court cards. Modern printing techniques use high-resolution images and precise color matching to ensure consistency and quality across the entire deck.

3. Cutting the Sheet Materials

The heart of our discussion is the cutting process. After the sheets of paper are printed with the designs for the entire deck, they must be cut into individual cards. This is where precision and technology come into play.

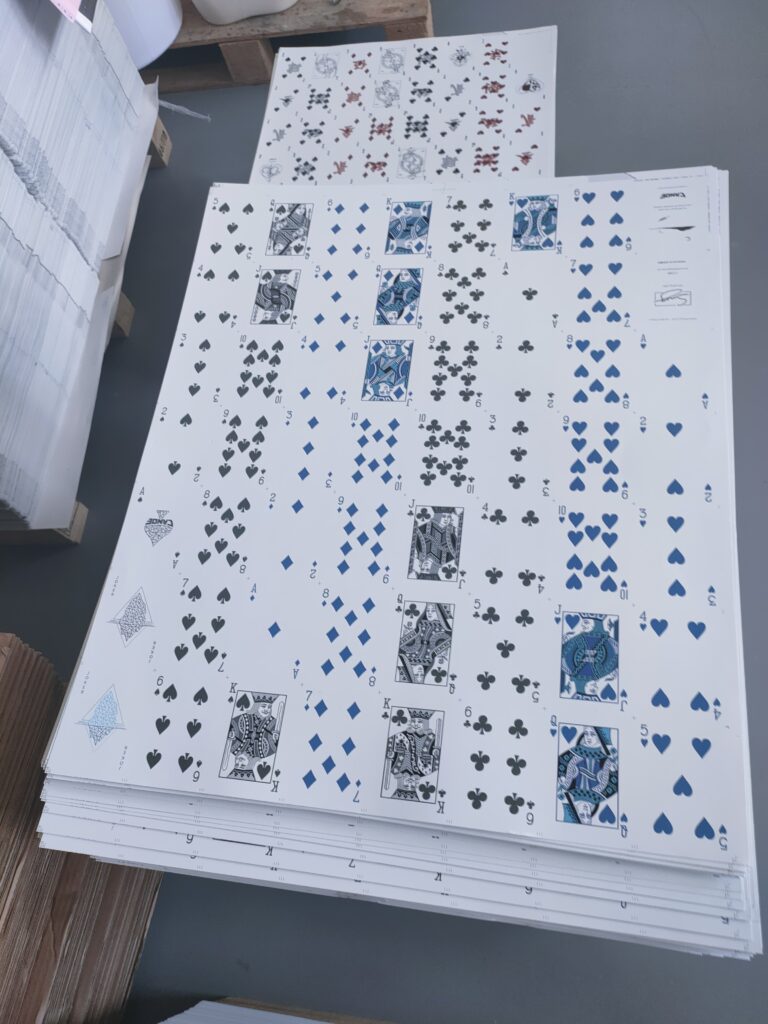

a. Sheet Layout

The layout of the cards on the sheet is crucial. Each sheet is carefully designed to maximize space and minimize waste. Typically, a sheet will contain multiple rows and columns of cards, with each card’s design perfectly aligned to ensure accurate cutting.

b. Cutting Technology

The cutting process has evolved significantly over the years. Early methods involved manual cutting, which was time-consuming and prone to errors. Today, automated cutting machines use advanced software and razor-sharp blades to cut the sheets with pinpoint accuracy.

4. Quality Control

After cutting, each card is inspected for any defects, such as misalignments, cuts, or color inconsistencies. This quality control step is vital to ensure that each deck meets the high standards expected by players and collectors.

5. Finishing Touches

Once the cards pass quality control, they may undergo additional processes such as coating with a protective layer to enhance durability and provide a smooth finish. Some high-end decks may also be embossed or feature metallic inks for a luxurious feel.

The Role of Craftsmanship

While technology plays a significant role in the production of playing cards, the element of craftsmanship cannot be overlooked. Skilled workers are often involved in the design, quality control, and finishing processes, ensuring that each deck is not just a product, but a work of art.

The Future of Playing Card Production

As technology advances, we can expect further innovations in the production of playing cards. From eco-friendly materials to augmented reality integration, the future holds exciting possibilities for this classic form of entertainment.

Conclusion

The process of cutting sheet materials to create individual playing cards is a fascinating blend of history, technology, and craftsmanship. From the selection of paper to the final product, each step is crucial in producing a deck that is both functional and aesthetically pleasing. As we continue to innovate and refine this process, the playing card remains a timeless symbol of entertainment and tradition.