Beginner’s Guide to Die Cutting Knowledge

blog 2024-10-28 02:42:26 143

Beginner’s Guide to Die Cutting Knowledge

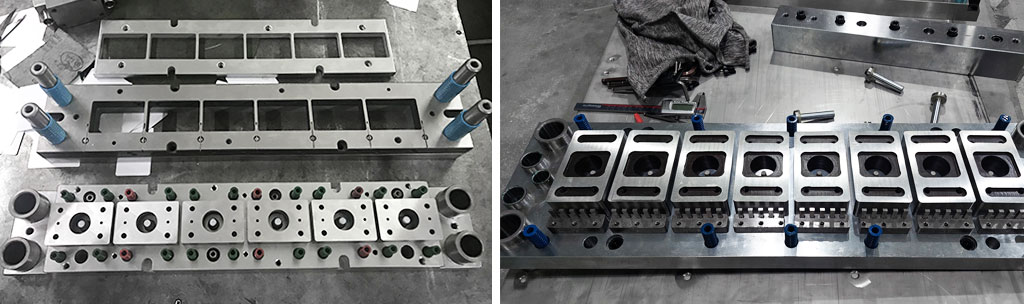

What is a mold?

A mold is a tool used in industrial production for shaping or processing materials, defining the shape, size, and surface characteristics of the finished product. Molds are typically made from metals or other high-strength materials such as steel, aluminum, copper, or other alloys that can withstand the pressures and wear of the forming process. The design and manufacturing of molds is a complex process that takes into account factors like material flow, shrinkage rates, ejection methods, and durability. High-quality molds can increase production efficiency, ensure product consistency and accuracy, and reduce manufacturing costs.

What is die cutting?

Die cutting, also known as die stamping or pressure cutting, is a fabrication technique that uses rigid cutting tools, known as dies, to cut materials. The purpose of die cutting is to precisely cut raw materials into predetermined shapes and sizes to produce the required product components or finished goods.

The die-cutting process usually includes the following steps:

1.Design: Design the pattern or shape to be cut according to the product requirements.

2.Making the knife mold: according to the design drawing to make the corresponding hard tool, knife mold is usually made of steel or high hardness alloy material.

3.Positioning: The die is placed on the material to be cut to ensure accurate positioning.

4.Cutting: The die is cut into the material by pressure, following the shape of the die.

5.Scrap Removal: The scrap produced after cutting is stripped from the product, leaving the desired shape.

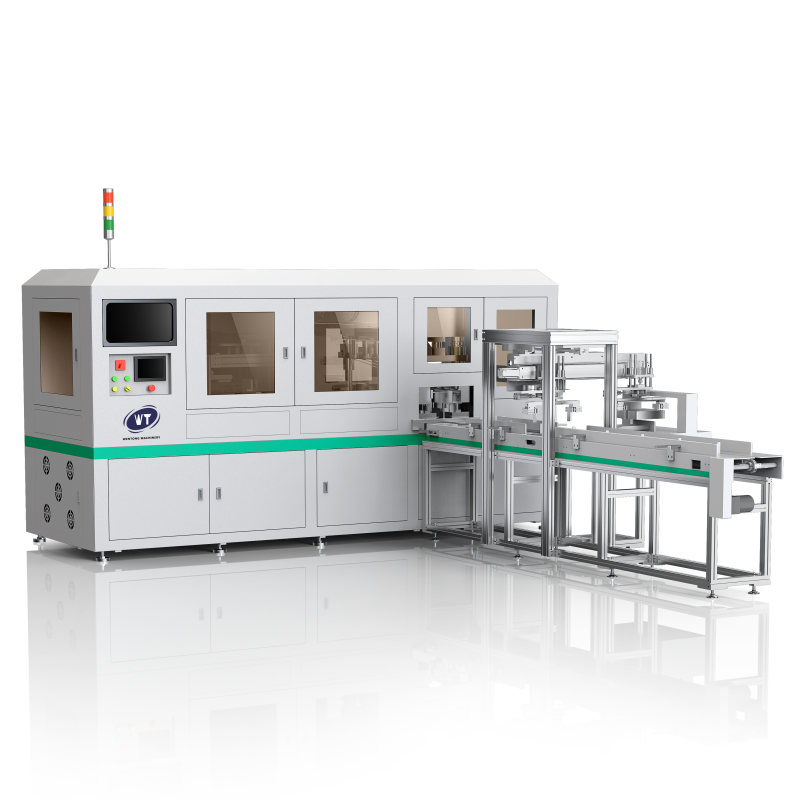

What is a die cutting machine?

Die cutting machine is a kind of mechanical equipment used to cut paper, plastic, leather, fabric and other materials into various shapes. It is widely used in packaging and printing, shoe making, clothing, bags and other industries. The working principle of the die cutting machine is through the movement of the upper and lower knife die, the blade on the knife die contact with the material and apply a certain strength, so as to cut the material into the required shape. The main components of the die cutting machine include the frame, transmission system, upper and lower knife die and control system. The frame is the main structure supporting the whole machine, the transmission system is responsible for transmitting power and motion control, the knife die is an important part of the cutting, and the control system is used to control the operation of the whole machine.

The working process of the die cutting machine can be divided into the following steps:

1.Preparation: First, prepare the material to be cut and fix it on the working table. At the same time, select the appropriate knife die according to the need and make sure it is firmly installed.

2.Motion control: Start the control system and set the parameters of cutting size, depth and speed through the operation panel or computer interface. The control system will control the motion of the transmission system according to these parameters.

3.Upper and lower knife die movement: the transmission system will drive the movement of upper and lower knife die through the motor, reducer and other devices. The upper die is pressed down, the blade is in contact with the material and exerts a certain force to cut the material. Then, the upper die lifts up, disengaging the material. The lower die rises, ready for the next cut

There are many types of die cutting machine, including automatic die cutting machine, full automatic die cutting machine, circular pressure circular die cutting machine, self-adhesive die cutting machine, flat pressure die cutting machine, hot stamping die cutting machine, manual die cutting machine, circular pressure die cutting machine, printing die cutting machine and so on.

What materials can be die cut?

1.Adhesive materials: These include double-sided adhesives, such as 3M468, 467, etc. These materials can be further categorized into substrate-free and adhesive with substrate. Substrate-free adhesive is directly coated on the release paper, while adhesive with substrate is coated on PET film, cotton paper or non-woven fabric. Acrylic adhesive and silicone rubber are common adhesive system materials used to bond different object surfaces.

2.Paper materials: die-cutting machines can die-cut all kinds of paper and cardboard, which are widely used in packaging, printing and other industries.

3.Non-paper materials: including self-adhesive, foam, mesh, etc. These materials are widely used in electronics, automotive, medical and other fields.

4.Release materials: generally used in die cutting as isolation, filling, protection, tape release, product cover, etc., with the benefit of easy peeling. Commonly used release substrates include Grazian paper, CCK kaolin coated paper, lamination paper, PE film, PET film, etc.

5.Adhesive series materials: these materials are very important in the die-cutting industry, including a variety of double-sided tape and other adhesive products.

6.Conductive shielding materials: used in the electronics industry to provide electromagnetic shielding effect.

7.Surface protection series materials: used to protect the product surface, to prevent scratches and pollution.

8.Sealing/cushioning series materials: used to provide sealing and cushioning effects, such as sealing gaskets, cushioning pads and so on.

9.Insulation and Flame Retardant Series Materials: Used in electronic and electrical products to provide insulation and flame retardant functions.

10.Waterproof and Dustproof Series Materials: Used in products that require waterproof and dustproof protection.

11.Backlight Module Series Materials: Used in the manufacture of LCD backlight modules.

12.Other materials: including rubber and plastic products, automotive parts, electronic parts, medical devices and accessories, shoe uppers, shoe soles, and fabrics.

What Do You Need To Start Die Cutting?

To start a die cutting operation, you need to prepare the following basic equipment and materials:

1.Die cutting machine: This is the core equipment for the die cutting process and can be manual, semi-automatic or fully automatic, depending on your production needs and budget.

2.Dies (knife dies): customized dies based on the shape and design you need to die cut. Dies are usually made of steel or other hard materials to ensure accuracy and durability.

3.Material: the material you want to die cut, such as paper, plastic, metal, fabric, etc.

4.Cleaning tools: Used to remove waste and dust generated during the die-cutting process and keep the working environment clean.

5.Waste Collection Container: Used to collect the waste materials generated during the die cutting process.

6.Operator’s Manual and Safety Guide: The operator’s manual and safety guide for the die cutting machine to ensure proper and safe use of the equipment.

7.Software: If the die cutting machine supports automation and computer control, you may need appropriate software to design and control the die cutting process.

8.Training: Proper training for operators to ensure they understand how to operate the die cutting machine safely and efficiently.

Does mold size matter?

The size of the mold is very important in the die-cutting process because it directly affects the precision and quality of the product.

1.Matching of product size and mold size: The size of the mold needs to be closely matched with the size of the product design drawing. If the size of the mold is out of tolerance, it will lead to inaccurate dimensions of the die-cut product, thus affecting the quality and use of the product.

2.Mold precision: The precision of the mold directly affects the dimensional accuracy of the product. When designing the mold, it is necessary to take into account the characteristics of the special die-cutting materials and scale the dimensions appropriately according to the design and die-cutting experience.

3.Blade angle and finish: The blade angle and side finish of the mold have a significant impact on the quality and accuracy of the die-cut product. Sharp blade and smooth side can reduce the deformation and indentation of the product during the die cutting process.

4.Mold material and type: Different materials and types of molds have different effects on die cutting accuracy. For example, etching molds have higher precision and service life, and are suitable for die cutting products with higher precision requirements.

5.Maintenance and upkeep of dies: Regular inspection and maintenance of dies to ensure they are in good condition is critical to maintaining the accuracy and quality of die cut products. Worn or damaged molds can lead to poor product dimensions and cosmetic defects.

6.Consideration of Material Characteristics: The characteristics of different materials, such as shrinkage and flexibility, will also affect the selection of die size. For example, for materials with strong shrinkage, it may be necessary to make appropriate adjustments to the mold size during design.

7.The rationality of the production process: a reasonable die cutting process has a great impact on product quality. This includes the way the mold is used, die cutting speed, pressure and other factors, which are related to the adaptability of the mold size.

Therefore, the selection and control of the die size is one of the key factors to ensure the quality of the die cut products. In the die-cutting process, the die size must be accurately controlled to meet the requirements of product design and ensure the functionality of the product.

How do I store mold sets?

There are several key factors you need to consider when storing your mold sets to ensure their safety, ease of access, and long-term durability.

1.Using a Magnetic Storage System

Magnetic storage is ideal for molds because they prevent molds from sliding or falling and are easy to access. You can use magnetic boards or magnetic strips to store molds.

2.Mold Storage Boxes

Purchase or customize specialized mold storage boxes, which usually have separated slots to accommodate different sized molds. Make sure the box has enough space to store the molds and that the lid can be tightly closed to keep out dust and debris.

3.Drawer Storage

If you have a limited work area, consider using a storage cabinet with multiple drawers. Each drawer can be dedicated to a specific type of mold and can be distinguished by labels or color coding.

4.Upright Storage

For larger molds, consider using upright storage. Place molds in upright positions on shelves or cabinets to ensure they don’t tip over or bump into each other.

5.Sorting and labeling

Sort molds by type, size or frequency of use. Use a labeling or marking system to identify each mold so you can quickly locate the mold you need.

6.Protective measures

When storing molds, use soft cloths, foam, or other protective materials to prevent scratches or damage between molds.

7.Environmental Controls

Ensure that the environment in which you store your molds is dry, clean and at the proper temperature. Avoid storing molds in humid or extreme temperature environments as this may affect their performance and longevity.

8.Regular Maintenance

Regularly inspect molds for signs of rust, damage or wear. If any problems are found, clean or repair them promptly.

9.Avoid overloading

Do not place too many molds in the storage unit; this may result in deformation or damage to the molds. Make sure there is proper space for each mold.

10.Easy Access

Keep the most frequently used molds within easy reach for quick access. Less frequently used molds can be stored in more distant or less accessible locations.

Recommendations for two card die-cutting machines!

Exploring the world of die cutting machinery can be challenging, but there’s no need to go it alone. If you are new to the die-cutting field or have encountered difficulties in your practice, we are always ready to welcome your inquiries. With more than a decade of industry experience, our team can provide you with professional guidance and solutions to help you quickly overcome obstacles and improve your skills. Don’t hesitate to contact us!