How to choose between semi automatic and fully automatic poker card cutting machines?

blog 2024-11-20 00:18:29 51

Differences Between Semi Automatic and Fully Automatic Poker Card Sheet Cutting Machines

Introduction

In the poker card manufacturing industry, cutting machines are indispensable equipment. With the development of technology, cutting machines have evolved from semi-automatic to fully automatic, with significant differences in operation, efficiency, cost, and application scenarios. This article will delve into the differences between semi-automatic and fully automatic cutting machines to help businesses make more suitable choices based on their own needs.

Features of Semi Automatic Cutting Machines

Degree of Automation

Semi-automatic cutting machines require manual operation, including steps such as feeding, positioning, and unloading. Operators need to manually control the movement and tilt of the cutting head, as well as the cutting speed. The operation of this equipment depends on the worker’s skills and experience, which can lead to fluctuations in precision and efficiency.

Precision and Efficiency

Due to the reliance on manual operation, the precision and efficiency of semi-automatic cutting machines are relatively low. The instability of manual operation can lead to variations in cutting quality, and the efficiency is not as good as automated equipment.

Cost and Maintenance

The purchase cost of semi-automatic cutting machines is relatively low, but they may require more manual maintenance and operation. In the long run, this could lead to higher labor costs and maintenance expenses.

Safety

Semi-automatic cutting machines require manual intervention during operation, which poses certain safety risks. Improper operation may lead to work-related accidents.

Features of Fully Automatic Cutting Machines

Degree of Automation

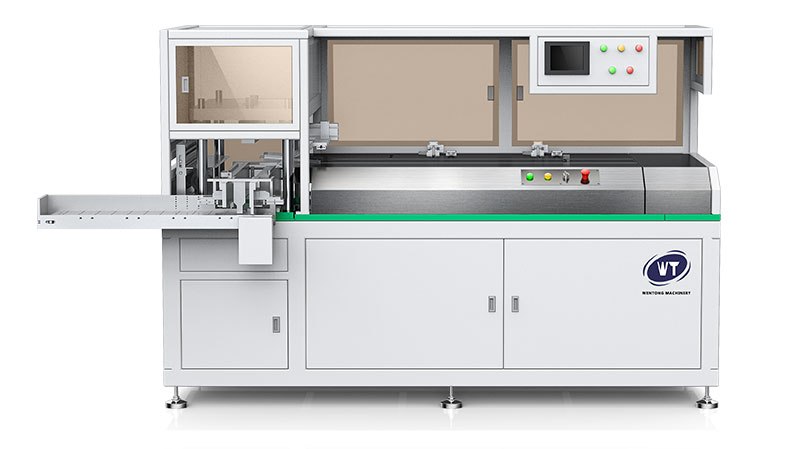

Fully automatic cutting machines achieve a higher degree of automation, capable of automatic feeding, positioning, and cutting. Controlled by computers, they can operate, cut, and position material lengths automatically.

Precision and Efficiency

Fully automatic cutting machines use computer control to achieve higher cutting precision and efficiency. They can control the movement and cutting speed of the cutting tool, resulting in high-precision and low-error products.

Cost and Maintenance

Although the initial investment cost of fully automatic cutting machines is higher, in the long term, their high efficiency and precision can reduce production costs and decrease manual intervention, thereby reducing maintenance needs.

Safety

Fully automatic cutting machines are equipped with multiple safety protection measures, such as safety barriers and emergency stop buttons, to ensure the safety of operators.

Comparison of Semi-Automatic and Fully Automatic Cutting Machines

Function and Application

Semi-automatic cutting machines have relatively simple functions, suitable for cutting parts with regular shapes, and are not suitable for single-piece, small batch, and large workpiece cutting. In contrast, fully automatic cutting machines have strong adaptability, suitable for cutting various materials, and can cut complex geometric shapes.

Waste Material Handling

Fully automatic cutting machines can achieve centralized collection of production waste, keeping the working environment clean, while semi-automatic cutting machines require manual waste handling, which is less efficient.

Market Adaptability

As the poker card market continues to expand, especially with the increase in personalized and customized demands, fully automatic cutting machines, with their high efficiency and precision, are better suited to meet market demands.

Conclusion

Semi-automatic and fully automatic cutting machines each have their advantages and limitations. Semi-automatic cutting machines are cost-effective and flexible in operation but have lower efficiency and precision, making them suitable for small-scale production and simple cutting tasks. Fully automatic cutting machines, although with higher initial investment, are more suitable for large-scale, high-precision production needs due to their high efficiency, precision, and safety. Businesses should make comprehensive considerations based on their production scale, product demands, and budget when choosing. With technological advancements, the advantages of fully automatic cutting machines will become more apparent and are expected to play a greater role in the future poker card manufacturing field.