The market advantage of the intermittent feeding die-cutting machine with the characteristics of short, flat, and fast

blog 2025-10-13 01:40:05 26

The market advantage of the intermittent feeding die-cutting machine with the characteristics of short, flat, and fast

We are a professional manufacturer of step-by-step feeding die-cutting machines in Shenzhen. We focus on overseas markets and understand and meet the needs of overseas card manufacturers (such as manufacturers of game cards, membership cards, smart cards, etc.). We see a clear trend that demand is shifting from “large-volume, large-scale production” to “small-volume, high-frequency switching.” In response to this trend, the stepping die-cutting machine we designed takes “short, flat, and fast” as its core characteristics and effectively solves the problems of efficiency, quality, and cost in the production of small batch orders. We will update and design the equipment for small batch production and high frequency of customer inquiries.

2-1024x868.jpg)

1. What is the “short, flat, fast” of the step-by-step feeding die-cutting machine?

The key pain points of small batch order production include “tight cycle, high cost, and easy rework.” The characteristics of “short, flat, and fast” effectively solve these problems:

“Short”: The mold change time is very short for small batch orders. The entire process of “feeding-die cutting-automatic sorting and sorting” does not require connection to external equipment. Cards of different materials, such as plastic game cards and wooden cultural and creative cards, can be completed in 1 to 2 steps. Traditional equipment requires manual sorting after die-cutting, while our small orders can save 1-2 hours per batch, saving the painful time of small orders.

“Flat”: Small-batch orders have small profit margins, and the equipment minimizes profit losses. High-precision stepper feeding, the edge of the card also has “no connection point,” the yield of plastic cards is more than 99.9%, all cuts are within 0.1 mm, and the edge is intact. This design completely eliminates the auxiliary work of rework at the end of the packaging process after the traditional machine is loaded and positioned for small batch production, and the small batch production is directly packaged.

“Fast”: Customs clients describe their orders as “multiple batches per week, small batches, and high-frequency switching.” For example, in one week, they may order three batches of customized membership cards and two batches of holiday game cards. Traditional systems require 1-2 hours to change orders and debug, while our system only needs 5-15 minutes to change orders and molds. We can arrange 4-5 small order batches a day, exceeding the limit of 2-3 batches a day for traditional units.

2. Express order replacement

It meets the needs of small orders and fast turnover. The long changeover time leads to a sharp decline in overall efficiency. The quick changeover capability of the step-and-repeat die-cutting machine is developed to cope with the high-frequency switching of small batches. Operating the machine requires only two basic steps. The step-and-repeat die cutter’s order changeover template also drives efficiency:

Call preset parameters;

store more than 100 order parameter templates. For example, when sorting, there is no need to re-debug, and the system parameter templates, such as die-cut game cards and feeding speed, as well as the sorting rules for member cards of specific specifications, can be directly called.

Automatic system linkage:

The parameters of the feeding, die-cutting, and sorting systems respond synchronously, and the production of the next batch of small orders can be completed in 5-10 minutes.

In terms of cost savings, taking overseas customers as an example, he processes an average of 4 batches of small orders (500-1000 cards per batch) every day. Traditional production equipment requires 4-6 hours to change orders, while this new equipment only needs 15 minutes. The equipment can produce 1-2 more small order batches per day and increase the revenue by 3,000-5,000 US dollars per month. At the same time, it saves 2 manual debugging personnel, saving $1,000-3,000 in labor costs per month (calculated at $5-25/hour in Europe and the United States).

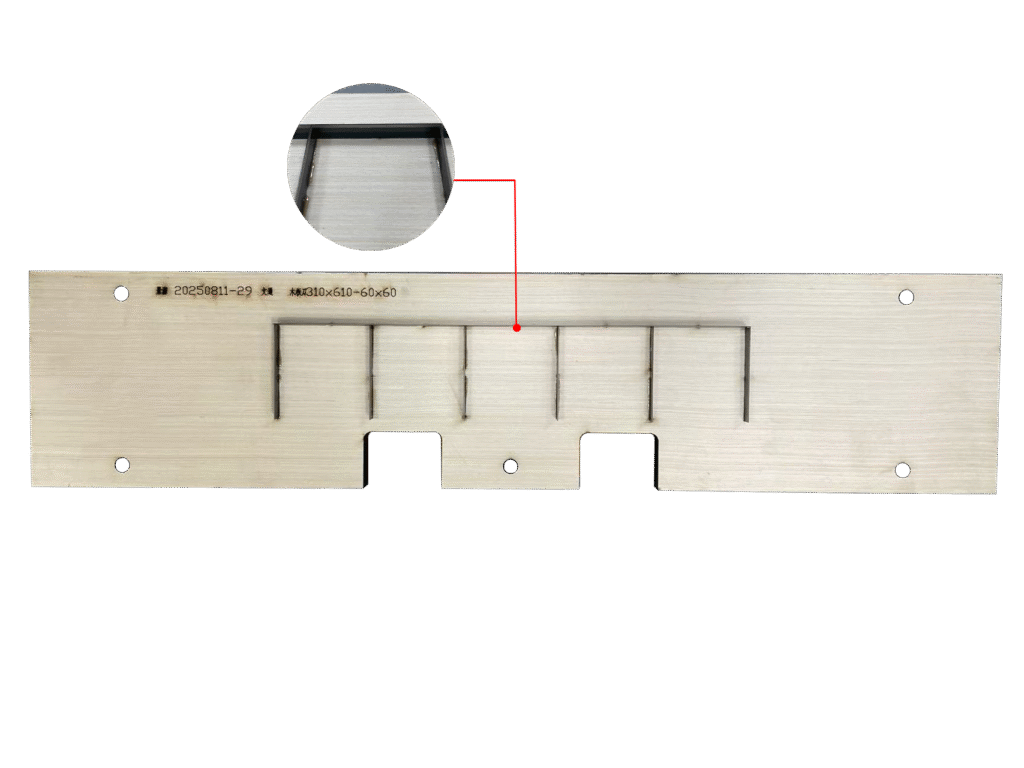

3. Quick mold change

Small-batch orders are often accompanied by the need for “multiple specifications.” For example, a standard 86 mm x 54 mm membership card can be easily turned into a 54 mm x 54 mm mini game card. For traditional production equipment, each time a different mold is used, the equipment needs to be disassembled and recalibrated. This takes 2-3 hours. The “quick mold change” function of this new equipment is designed for small-batch and multi-specification production.

Simple operation:

No professional tools are required. The steps are limited to opening the mold buckle, inserting and replacing the standardized knife mold, and letting the equipment infrared self-calibrate (error ≤ 0.05 mm). The whole process takes only 15 minutes.

Suitable for all materials:

whether they are plastic game cards/smart cards or wooden creative cards, the mold switching is quick and convenient to adapt to production. This technology meets the diverse material and specification requirements of small-batch cards overseas.

4. Automatic sorting and distribution

Overseas, especially in Europe and the United States, labor costs are high (5-25/hour). It is easy to lose money when small batch orders need manual sorting. With our step-and-repeat automatic die-cutting machine, we help customers maintain profits through sorting and automation systems.

Reduce labor: Overseas, especially in Europe and the United States, labor costs are high ($5-25/hour). It is easy to lose money when small batch orders require manual sorting. With our step-and-repeat automatic die-cutting machine, we help customers maintain profits through sorting and automation systems.

Avoid losses: When manually preventing losses of small batches of cards, it is easy to mix orders (such as putting game cards of batch A into membership cards of batch B). The cost of rework can be thousands of dollars per batch. By contrast, the equipment’s ability to sort mixed orders and prevent losses ensures that small-batch orders are profitable. The reason why the equipment sorting can achieve the profit level of the loss-making mixed order is that its accuracy rate is as high as 99.9%.

5. Adaptability and after-sales service of step-by-step feeding die-cutting machine

The overseas expectations of small-batch customers for equipment are “stability” and “after-sales response speed” (once the machine is down, the delivery time of small orders is easily delayed). We provide them with the entire process from design to service.

Localized system. The system is dual voltage for 110V (US/EU standard) and 220V (most of the world), so no additional transformer is required. The system has eight built-in languages, including English, Spanish, and German, to help workers get started quickly.

Global certifications: CE (EU), FCC (US), and ISO9001, ensuring no additional compliance procedures are required for overseas markets.

Fast after-sales service: To ensure a fast response to after-sales service, three overseas service centers have been established in Germany, the United States, and India to provide 24-hour remote fault debugging (minor faults are resolved within 1 hour). If on-site maintenance is required, the service center can reach major customers in Europe and the United States within 72 hours to prevent small-batch production from stagnating due to equipment failure.

Summary

The step-by-step feeding die-cutting machine is outstanding in process efficiency, quality control, risk reduction, and rapid response to switching, and it is most in line with the needs of overseas small-batch card orders for “tight cycle, frequent switching, and cost sensitivity.” Combined with automatic sorting and overseas localization services, it provides cost-effective solutions for small-batch card production enterprises around the world. For small batch production of metal cards, plastic cards, and wooden cards, welcome to contact us; we will tailor a solution for you.