What should be paid attention to when purchasing a bank card die-cutting machine?

blog 2025-09-29 01:30:26 37

What should be paid attention to when purchasing a bank card die-cutting machine?

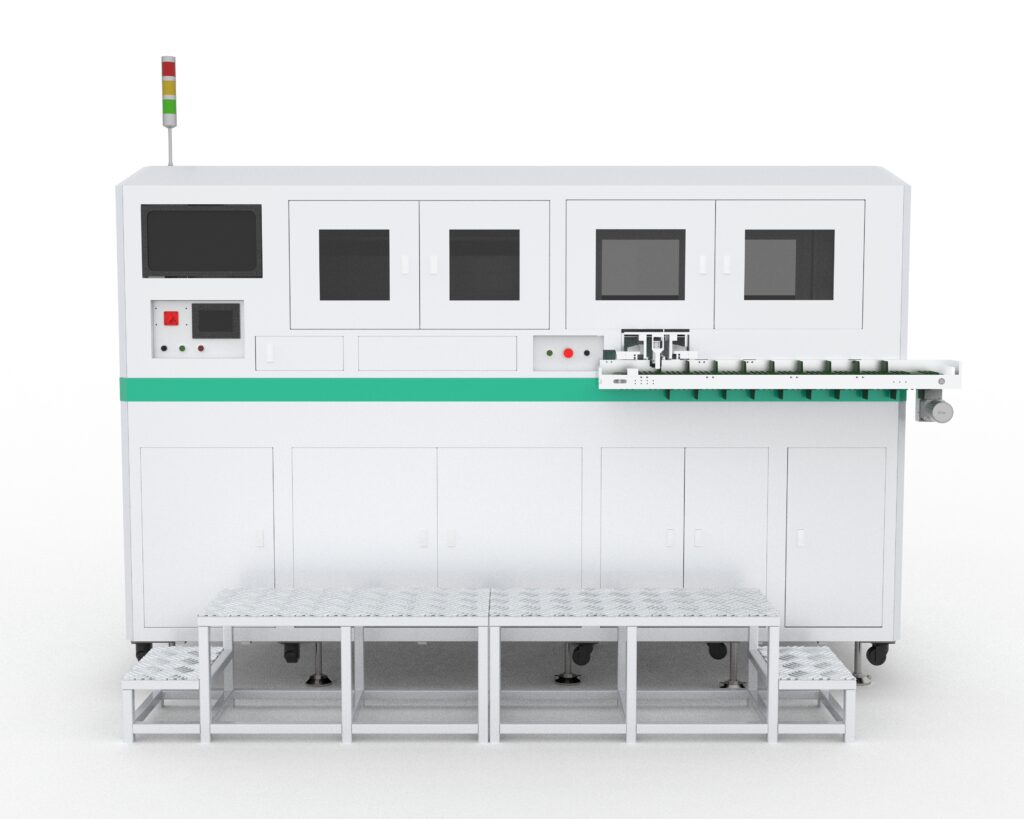

As a Shenzhen bank card punching machine manufacturer, we mainly face the overseas market. We understand that overseas customers have high requirements for the professionalism, practicality, and cost performance of the card punching machine. Our bank card die-cutting machine can process game cards, membership cards, smart cards, bank cards, and other cards. It can also process other products such as metal cards, wood cards, plastic cards, and books, and it has automatic classification and sorting functions. The following will introduce you to several key points to note when purchasing.

1. How to choose the right model of bank card die-cutting machine?

Choosing the right model is the first step in purchasing, and the production needs must be correctly analyzed:

Clarify the type of products to be produced:

If the products to be processed are mainly plastic cards, especially bank cards and smart cards, it is best to choose a model specially designed for plastic processing to ensure that the die-cutting accuracy reaches the best level in the industry. If there is also the production of metal cards, wooden cards, and other products, it is best to choose a model with high strength and wear resistance of the die-cutting tool to avoid excessive shrinkage of the equipment. For large-format materials such as books and periodicals, the maximum processing width of the machine is a key consideration, and it is necessary to ensure that its processing width meets the production needs.

Consider automation needs:

When the production scale is large, the cards need to be classified and sorted after production, and the cards need to be completed quickly; the model integrated with the automatic sorting machine should be selected. This can greatly reduce the need for manual sorting, maximize production efficiency (in most cases, sorting efficiency can be increased by more than 30%), minimize sorting errors, and reduce labor costs.

Matching overseas production scenarios:

Adapting to overseas production scenarios:In response to the different voltage and interface standards of overseas customers, as well as the customized needs of production scenarios, our company’s equipment has multi-voltage adaptability (110V-240V) and universal interface selection. Please specify the parameters of the production scene when ordering. We will be happy to provide model adaptation to help the equipment integrate into the local production scene.

2. How to ensure the long-term production benefits of a bank card die-cutting machine when purchasing?

Consider the long-term production efficiency, after-sales support, and equipment maintenance costs of production equipment:

Strictly control the quality of the core components of the equipment:

the core components of the equipment must be of high quality. The die seat of our bank card die-cutting machine adopts imported steel and is equipped with a high-precision servo motor. The expected service life is 8-10 years. This is far higher than the industry average of 5-6 years. In addition, the most critical components of the equipment are equipped with intelligent monitoring sensors to observe the wear of the components in real time and prevent unexpected failures from causing production shutdowns.

Attach importance to overseas after-sales service guaranty:

Shenzhen headquarters has a special overseas after-sales service team. When purchasing, make sure that the supplier can guarantee after-sales support. For example, we offer 24/7 remote technical guidance, and for complex problems, we can dispatch engineers for on-site maintenance within 48 hours, depending on your location (we cover major markets worldwide). In addition, confirm the delivery time of spare parts. We will set up warehouses in various regions around the world to store spare parts to ensure that we meet your needs by delivering damaged parts within 3-5 days, thereby greatly reducing equipment downtime.

Assess long-term maintenance costs:Analyze the long-term cost of ownership:

Quality machinery can reduce maintenance costs. Our machines are modular, allowing for quick and easy part replacement. Specialist technicians make repairs more efficient, while the need for specialist technicians during basic maintenance reduces ongoing costs. In addition, the machine is optimized to minimize energy use, consuming less than five kilowatts per hour, resulting in long-term savings on electricity bills and maintaining production profits.

3.How to consider the return on investment when purchasing a bank card die-cutting machine?

Foreign customers are mainly concerned about the return on investment. The analysis should be conducted from the aspects of investment cost, production efficiency, and profit margin.

Keep initial investment under control:

There is no need to waste money on machines that are too expensive. Instead, the scale of production dictates the choice of models that reflect the best value. We offer multiple tiers based on customer needs. Small businesses can adopt the basic model, which is affordable and supports small- and medium-sized batch production. Large enterprises should adopt the top-level model of automation, flexibility, large scale, and customization to achieve multi-product compatibility. This ensures that the main costs are in line with production needs, thereby minimizing resource waste.

Measuring the impact of production efficiency on returns:

The production efficiency of equipment directly determines the speed of profit acquisition. For example, our terminal equipment can die-cut 1,500-2,000 cards of various types per hour, which is 25% higher than the average equipment. Assuming 8 hours of production, the profit of each card is 0.5 yuan, and the annual profit can reach 100,000-150,000 yuan, shortening the investment payback period. The payback period is 1.5-2 years. Our average model can also achieve this. The die-cutting speed is 1500-2000 cards per hour, and the efficiency is 25% higher than that of standard equipment. With 8 hours of production per day and a profit of 0.5 yuan per card, the annual profit can reach 100,000 to 150,000 yuan, and the investment can be recovered in an average of 1.5 to 2 years.

Expand profit space:

Bank card equipment has flexible equipment processing capacity, and the multi-product processing capacity of the equipment can realize the expansion of business scope. For example, in addition to bank card production, the same equipment can also process game cards, membership cards, or metal commemorative cards. This allows for diversification of product types, thereby improving market competitiveness. The card production equipment also has automatic classification and sorting functions. It can be used to process other jobs, further expand profit opportunities, and optimize the return on investment.

Based on the above factors, it can be seen that the purchase of bank card die-cutting machines should be based on the three core concepts of “selection, long-term profitability, and return on investment.” Comprehensive decision-making includes production needs and the range of profits, overseas utilization scenarios, and profit targets. As a manufacturer based in Shenzhen, we are proud of the value, high-quality equipment, and full range of services we provide to our international customers, which enhance global competitiveness.