Three common problems of self-adhesive bag packaging machines

blog 2025-09-28 01:32:39 35

Three common problems of self-adhesive bag packaging machines

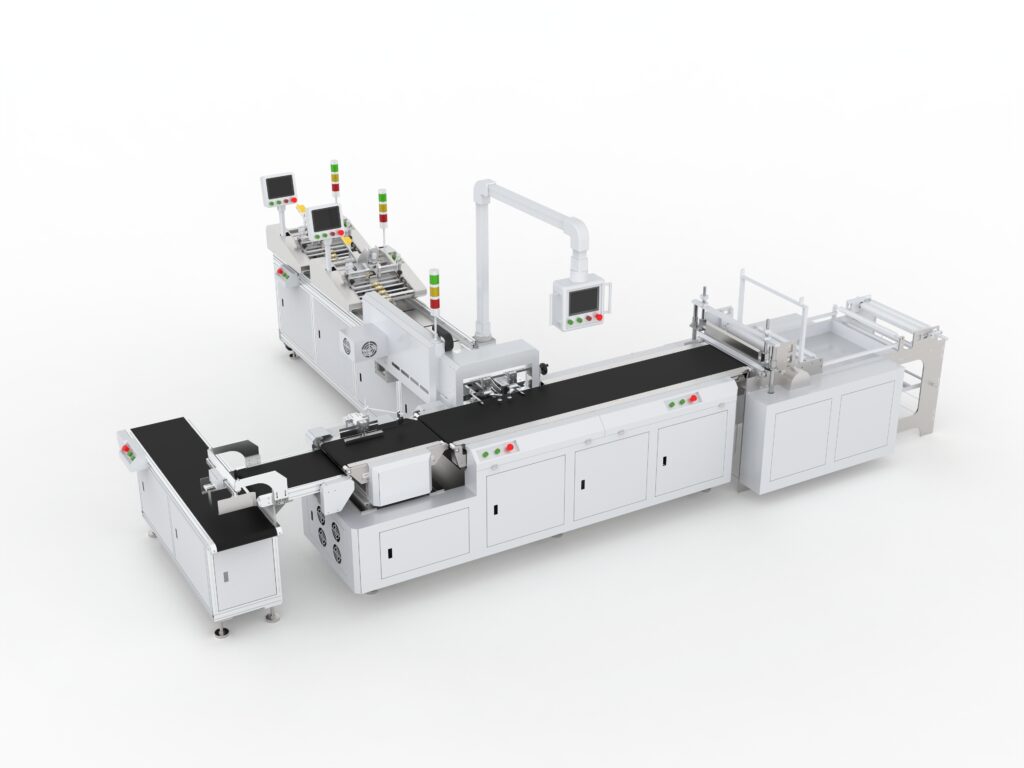

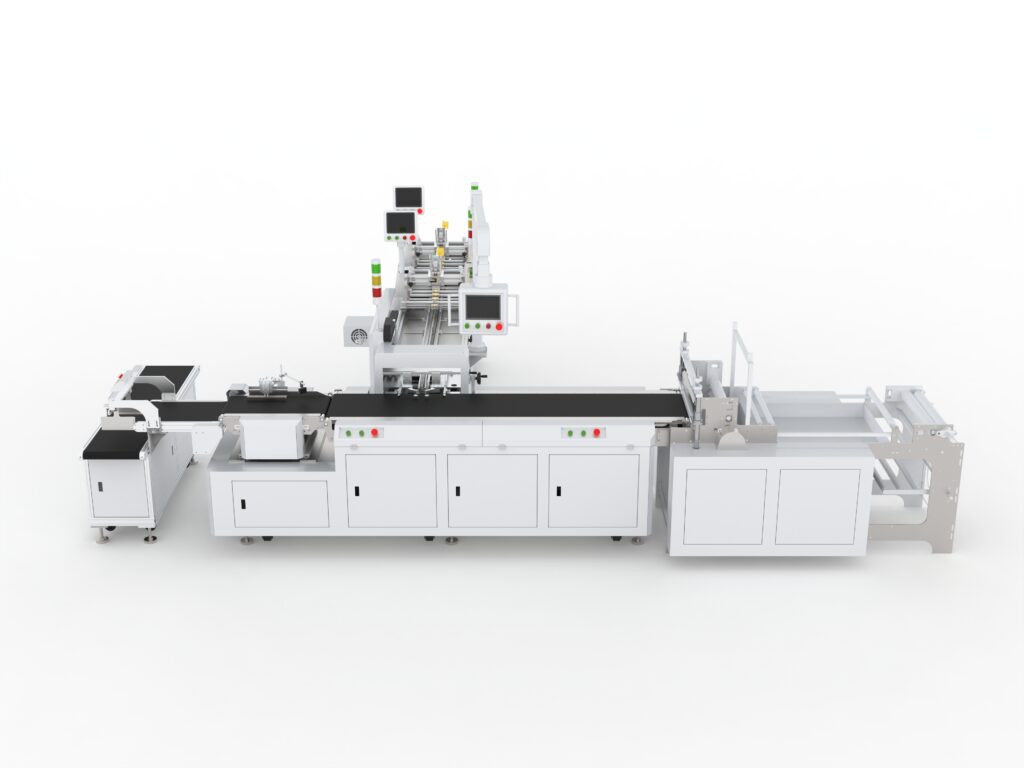

As a Shenzhen self-adhesive bag packaging machine manufacturer, we mainly export our products. According to our experience, we understand the issues that overseas customers are most concerned about when purchasing and using the equipment. Therefore, based on the understanding of the production characteristics of the equipment and the needs of the target population, we strive to clarify the common questions related to the self-adhesive bag packaging machine to facilitate customers making decisions.

1. What are the core factors that affect the price of a self-adhesive bag packaging machine?

There is no clear price for the self-adhesive bag packaging machine because there are many factors that determine the price, so overseas customers need to be more patient in this regard. In this regard, overseas customers should understand the following differences in configuration:

The core configuration differences:

The models with autonomous sorting function are priced higher than the basic packaging models due to the adoption of advanced intelligent sensing modules. Prices also vary depending on the adjustable feeding mechanism and scratch-resistant conveyor, which can accommodate a variety of materials, such as metal, wood, and plastic cards.

Capacity and specifications match:

High-volume models used for large-scale production (more than 5,000 items packaged per hour) are always priced higher than small desktop models. This is because high-volume models contain more powerful and larger hopper drive systems. In addition, there are more expensive wide-format packaging models, because their body structure and packaging modules have been upgraded. They can package extra-large products, such as textbooks.

Customized requirements:

As the packaging of special products such as game cards, membership cards, and smart cards requires hardware modifications such as software coordinates, precise positioning and labeling, and sealing, the increase in customized functions will also increase the cost accordingly. The localization requirements of overseas customers, such as voltage conversion (110V/220V) and language control system, will also be included in the cost.

2. What are the main application scenarios of the self-adhesive bag packaging machine?

Self-adhesive bag packaging machines are used in various fields around the world due to their automation features. The main highlights include

Card manufacturing industry:

Used for packaging various cards such as game cards, membership cards, and smart cards. The anti-scratch self-adhesive bag conveying channel is adopted to meet the wear-resistant packaging requirements of metal cards. The integrated ion wind elimination device can relieve the electrostatic protection of plastic cards, and the automatic sorting function can realize the classification and packaging of cards of various specifications and sizes so as to improve the production efficiency.

In the cultural education and handicrafts industries:

Suitable for moisture-proof packaging of wooden cards, paper bookmarks, and other similar products, and small books, albums, and other products are sealed and packaged with plastic film. The equipment can automatically adjust the packaging spacing according to the thickness of the book, and the self-adhesive bag is sealed with firm sealing.

Small commodity manufacturers:

For small-batch, multi-specification products, automatic classification optimizes the “packaging + sorting” operation and minimizes manual sorting. This function is efficient and practical for the production needs of small plastic accessories, hardware jewelry, and other small-batch, multi-specification products of small and medium-sized processing plants overseas.

3. How does the Winton packaging machine’s after-sales service cover the global overseas market?

As a Shenzhen enterprise based on the overseas market, Wentong Packaging Machinery has established a perfect global after-sales service system for overseas customers.

Localized response mechanism: For equipment failures, spare parts warehouses are located in Europe, the United States, and Southeast Asia, providing 48-hour delivery service. A multilingual support team provides 24/7 remote diagnostics and troubleshooting.

Full-cycle technical support: Full-cycle support will include equipment setup, troubleshooting, and operator training on the basic functions of the automated sorting system. As part of the contract, you will also receive one or two on-site maintenance services per year. The maintenance services included cover the drive system, sorting module, and overall system maintenance and focus on the services you will receive. During the years you receive the service, you will enjoy a maintenance contract covering the service each year.

Long-term guaranty policy: The equipment maintains its original function and extends the service life of the equipment. Servo, motor, and control system warranty for 18 months, warranty period maintenance, and functional replacement of defective parts. You will also enjoy upgrade and retrofit services to adjust old equipment to meet the new specifications of new packaging requirements and new functions of old equipment.

In short, the self-adhesive bag packaging machine also includes cost, function, and after-sales support. The company has strong technical strength, can tailor-make for customers, and provides functional packaging, high investment return, and machine uptime support for global customers.