What are the advantages of semi automatic poker card cutting machines?

blog 2024-11-19 23:59:21 17

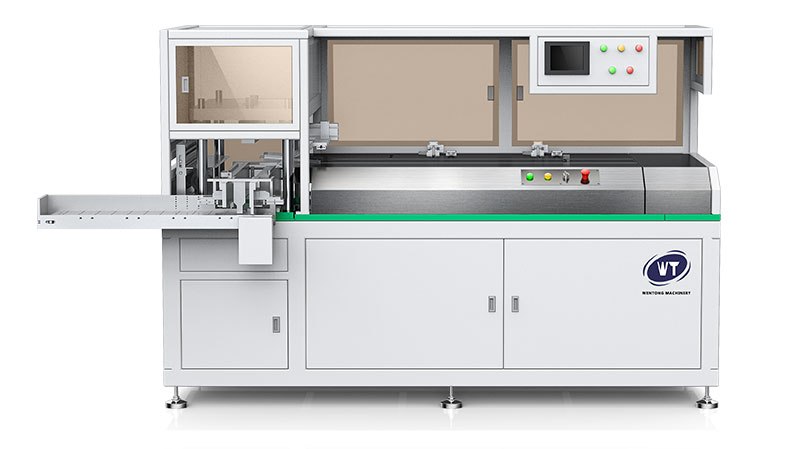

The Advantages of Semi Automatic Poker Card Sheet Cutting Machine

Introduction

In the poker card production industry, cutting machines are indispensable equipment. With the advancement of technology, the semi-automatic poker card sheet cutting machine has gained a foothold in the market with its unique advantages. This article will explore the main advantages of the semi-automatic poker card sheet cutting machine and how they improve production efficiency and product quality.

Technical Specifications Overview

Before delving into the details, let’s take a look at some key technical specifications of this semi-automatic poker card sheet cutting machine:

- Power Supply: AC 380V 150 HZ, with a total power of 6.5KW.

- Air Source: 6 kg/cm², with an air consumption of approximately 30L/min.

- Punching Pressure: 2T-6T, adaptable to cutting different paper thicknesses.

- Weight: Approximately 1000KG, ensuring stable machine operation.

- Cutting Precision: ±0.10mm, guaranteeing the consistency of poker card dimensions.

- Sheet Format: Maximum 1100700MM, minimum 297210MM, accommodating various paper sizes.

- Control Method: PLC control + servo/hydraulic system, enhancing the level of automation.

- Operators Needed: Only 1 person, reducing labor costs.

- Dimensions: L2400W1500H1700MM, suitable for most production environments.

- Drive Method: Servo/hydraulic system, providing stable power output.

- Punched Card Size: Maximum 210210MM, minimum 5454MM, meeting the size requirements of different cards.

- Productivity: 15000~30000PCS/H, significantly increasing production capacity.

High Efficiency and Capacity

The semi-automatic poker card sheet cutting machine boasts an extremely high production efficiency, capable of producing 15,000 to 30,000 decks of poker cards per hour. Such high capacity makes it an ideal choice for large-scale production. This increase in efficiency not only reduces production cycles but also lowers per-unit costs, enhancing market competitiveness.

Precise Cutting Precision

Cutting precision is one of the key factors in poker card quality. The machine’s cutting precision reaches ±0.10mm, which means that the dimensions of each deck of poker cards can be kept consistent, meeting strict quality control standards in terms of length, width, and thickness.

Easy Operation and Automation Level

The machine uses PLC control and a servo/hydraulic system, making operation more straightforward. Only one operator is needed to manage the entire production process, significantly reducing labor requirements and operational complexity. Additionally, this level of automation reduces the possibility of human error, improving product consistency and reliability.

Maintenance and Durability

The semi-automatic poker card sheet cutting machine has been designed with maintenance and durability in mind. The machine weighs approximately 1000KG, ensuring stability during high-speed operation. At the same time, all components of the machine are from well-known domestic and international brands, ensuring high performance and long life, reducing maintenance costs and downtime.

Safety Performance

Safety is an essential consideration for any mechanical equipment. The machine is equipped with necessary safety devices, such as an emergency stop button and limit switches, to ensure the safety of operators. Moreover, the machine’s design also considers dust and dirt protection to safeguard delicate parts from damage.

Conclusion

The semi-automatic poker card sheet cutting machine demonstrates significant advantages in the poker card production field with its high efficiency, precise cutting, easy operation, and strong durability. These advantages not only improve production efficiency but also ensure product quality, providing operators with a safer and more comfortable working environment. As technology continues to advance, the semi-automatic poker card sheet cutting machine will continue to play a vital role in the poker card manufacturing industry.