How to start your Efficient Card Production

blog 2025-08-31 20:46:12 9

Card punching & cutting equipment usage guide: How to make the card production more efficiently

How to start your Efficient Card Production

In modern industrial production, card punching& cutting equipment has become an key equipment for many card manufacturing companies due to its high precision and high efficiency. Whether it is printing, packaging and other industries. Card punching & cutting equipment can also be used to accurately process various materials like PC, PET, PP etc besides paper and PVC. Let us take a deep look at the usage methods and skills of this equipment to help you give full play to its powerful performance.

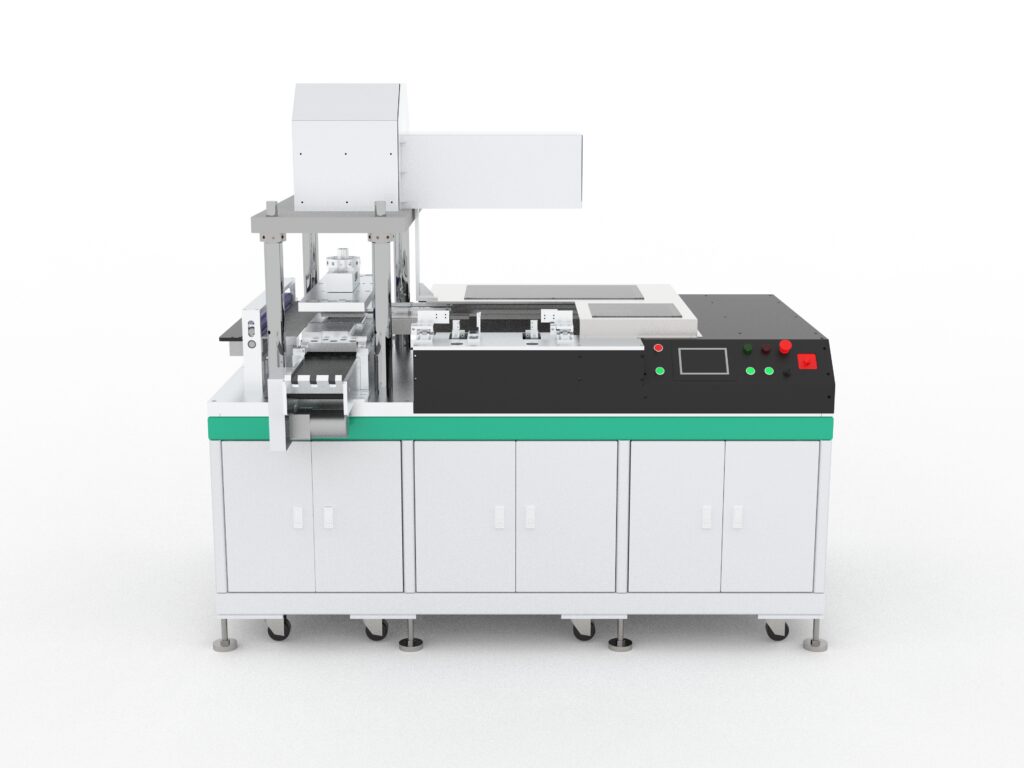

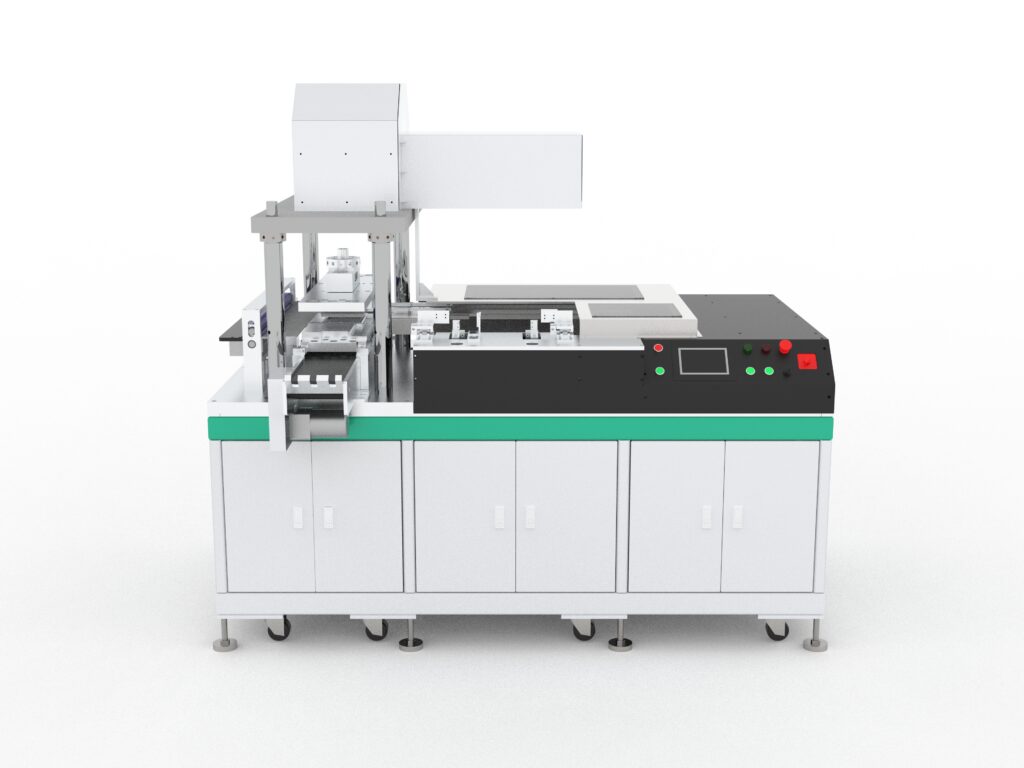

1.card punching machine Appearance and main components of the equipment

From the initial manual, to the later semi-automatic and then to the later fully automatic, the card punching machine has undergone several generations of updates and upgrades. Now the appearance is simple but beautiful, is highlights and sturdy. The main body of the equipment is made of a sturdy metal frame, which provides stable support for the entire operation process. 98% of the whole machine is made of metal, and only a few parts contain plastic. The operation panel is located at the front of the equipment, with various control buttons and display screens distributed on it. They are like the “brain center” of the equipment, allowing you to easily control the operation of the equipment.

In the operation platform of the Card Punching Machine, the core component punching mould is particularly important. The sharp and durable mould can accurately punch the material according to the preset pattern and size. At the same time, the material conveying platform should not be ignored. It is responsible for smoothly delivering the material to be processed into the punching area to ensure the continuity and accuracy of the punching process. In addition, the structural setting of the automatic pallet loading also greatly reduces the labor cost and provides convenience for actual production.

侧视角-1024x868.jpg)

2.Card Punching Machine Equipment installation and commissioning

When installing the card punching machine, please be sure to choose a flat and stable work site to avoid shaking or displacement of the equipment during operation, which will affect the punching accuracy. The main support of the machine is equipped with adjustable foot cups. Please be sure to adjust all foot cups to the best state.

According to the installation instructions attached to the machine, connect the power supply, air source and other lines in sequence, and ensure that the connection is firm and correct. Under normal circumstances, we have completed the testing and trial operation of the machine before leaving the factory. All settings are in accordance with the customer’s card layout and parameters. Basically, you only need to connect the power supply and air supply to power the machine on and start a trial running.

After the installation is completed, first, start the machine through the operation panel to observe whether the equipment runs smoothly and whether there is any abnormal noise or vibration. Before that, you need to print a batch of materials for testing the machine according to the card layout we confirmed (normally all materials are same printed as per the confirmed layout). Then, load the materials to the lifting platform in the correct direction. At the same time, check the current speed of the material conveying platform and whether the visual positioning has captured the printed cross mark point (normally, all have been well-set. If you need to re-set, please refer to the video and instructions we provide). During the trial running, you must be patient, and test repeatedly until the machine reaches the best operating state.

3.Card Punching Machine Detailed explanation of operation steps

(1). Material preparation: According to the corresponding materials and requirements of the mold, and ensure that the surface is flat and free of impurities. Place the materials neatly on the loading platform and lift the platform (the electric eye induction automatically stops lifting the material).

(2). Parameter setting: Enter the punching parameters you need on the operation panel, such as punching speed, quantity, etc. These parameters will guide the equipment to perform precise punching according to your requirements. At the same time, you can also adjust the step distance and correction system according to the characteristics of the material to achieve the best punching effect.

(3). Start the equipment: After confirming that all parameter settings are correct, press the start button. The equipment starts to run automatically, the material is transported to the working platform through the suction cup, the visual automatically identifies the mark point and correction, and the material is transported to the punching area by the chucks on both sides. The punching mold performs fast, continuous and precise punching of the material according to the preset parameters. During the punching process, you can monitor the operating status and punching progress of the equipment in real time through the display screen on the operation panel.

(4). Finished product collection: The finished product after punching is automatically discharged from the discharge port of the equipment. Because the cards are initially arranged according to demand, the finished product is a deck of cards that has been arranged. In this way, you only need to arrange staff at the discharge port to collect the finished products in time for subsequent inspection, packaging and other processes.

(5). (Optional) Packaging streamline: In order to achieve full automation of card production, our card punching machine can be directly connected to the packaging system. Popular packaging systems include strapping machines, cello-wrapping packaging machines, heat shrink machines, deck boxing machines, etc.

We provide all non-standard customized card production equipment and solutions.

4 .Card Punching Machine Daily maintenance and care

In order to ensure that the card punching equipment always maintains a good operating state and prolongs its service life, daily maintenance and care are essential. After work every day, debris, dust and other impurities on the surface and inside of the equipment should be cleaned in time to prevent them from accumulating inside the equipment and affecting the normal operation of the equipment. Regularly check the wear of the punching die. If the tool is found to be severely worn, it should be replaced in time to ensure the punching accuracy. At the same time, the transmission parts and lubrication system of the equipment should be inspected and maintained, and an appropriate amount of lubricating oil (1-2 drops) should be added every day to ensure smooth operation between the various parts of the equipment.

Our card punching machine is simple to operate and easy to use, especially accurate punching. The same machine is compatible with a variety of products, and multi-functional punching includes rounded corners, shapes, punching, etc. Inline packaging brings efficient and high-yield production experience to enterprises, creates greater value for your card production, and helps card production companies stand out in the fierce market competition.

Ready to automate your card production line?

Visit our Website: https://cardmakingmachine.com/ or contact us at 0086 13310872282 or email to WT03@cards-machiney.com for more information and explore a best solution for you.

Use Card punching machine from Wentong to standout your cards.